A continuous dehydration equipment for pickled vegetable raw materials

A technology for dehydration equipment and raw materials, which is applied in the field of continuous dehydration equipment for pickled vegetable raw materials, which can solve problems such as the inability to adjust the dehydration extrusion force, and achieve the effects of avoiding crushing or insufficient dehydration, ensuring the effect of turning, and saving labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

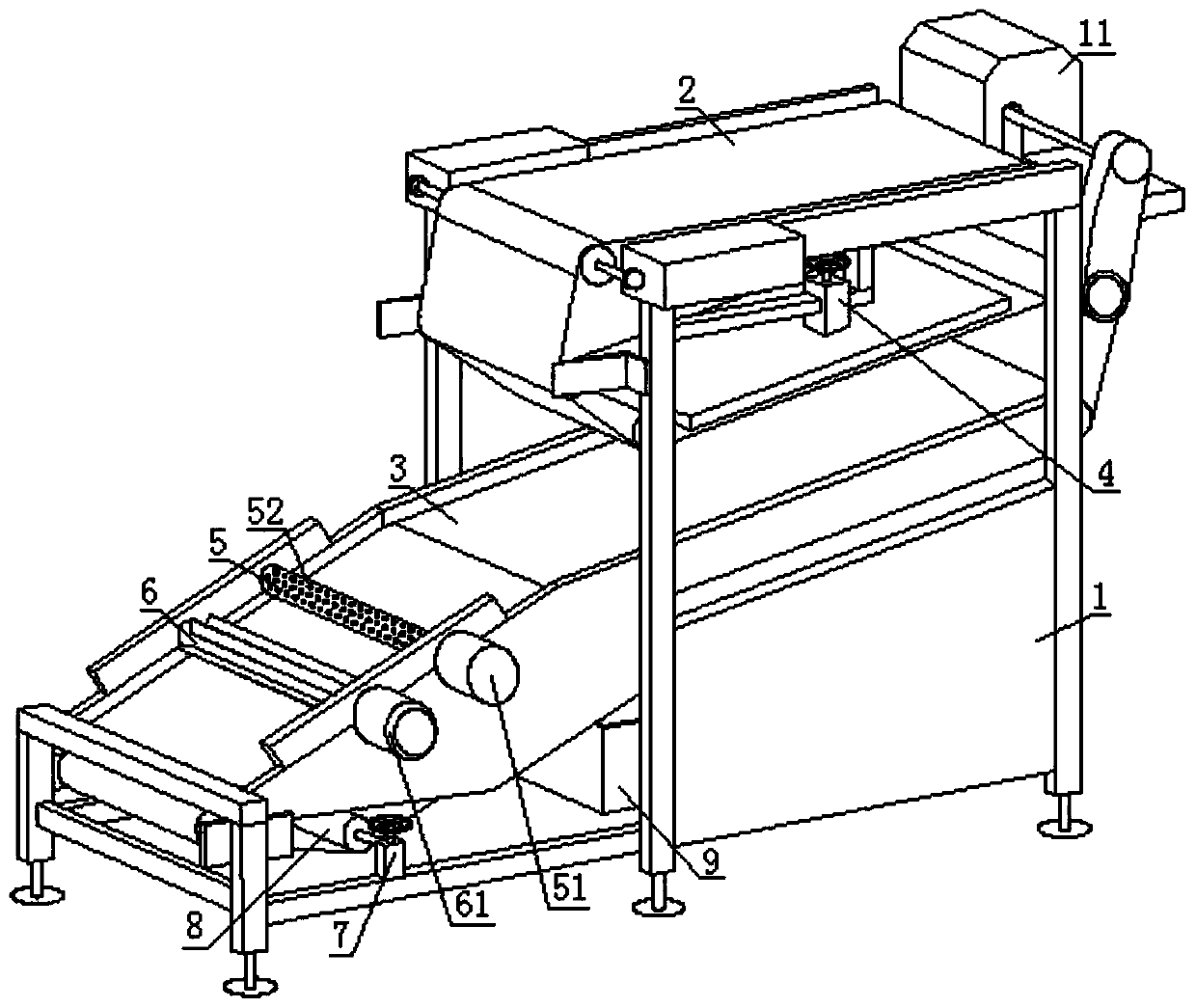

[0032] Such as figure 1 Shown, the present invention comprises frame 1, and upper extruding conveyer belt 2, lower extruding conveyer belt 3, variable speed driving device 11 are respectively installed on frame 1, and the output shaft of variable speed driving device 11 is respectively connected with the driving force of upper extruding conveying belt 2. The driving wheel of the wheel and the lower extrusion conveyor belt 3 is driven by a belt; it is characterized in that the frame 1 is also fixed with a booster device 4 for adjusting the extrusion force between the upper extrusion conveyor belt 2 and the lower extrusion conveyor belt 3 , the pressurizing device 4 is arranged in the upper extrusion conveyor belt 2; the frame 1 is also equipped with an air blowing mechanism 5 for blowing the extruded raw material from the lower extrusion conveyor belt 3 and for extruding The last raw material is turned over by the material turning mechanism 6, and the lower extrusion conveyor b...

Embodiment 2

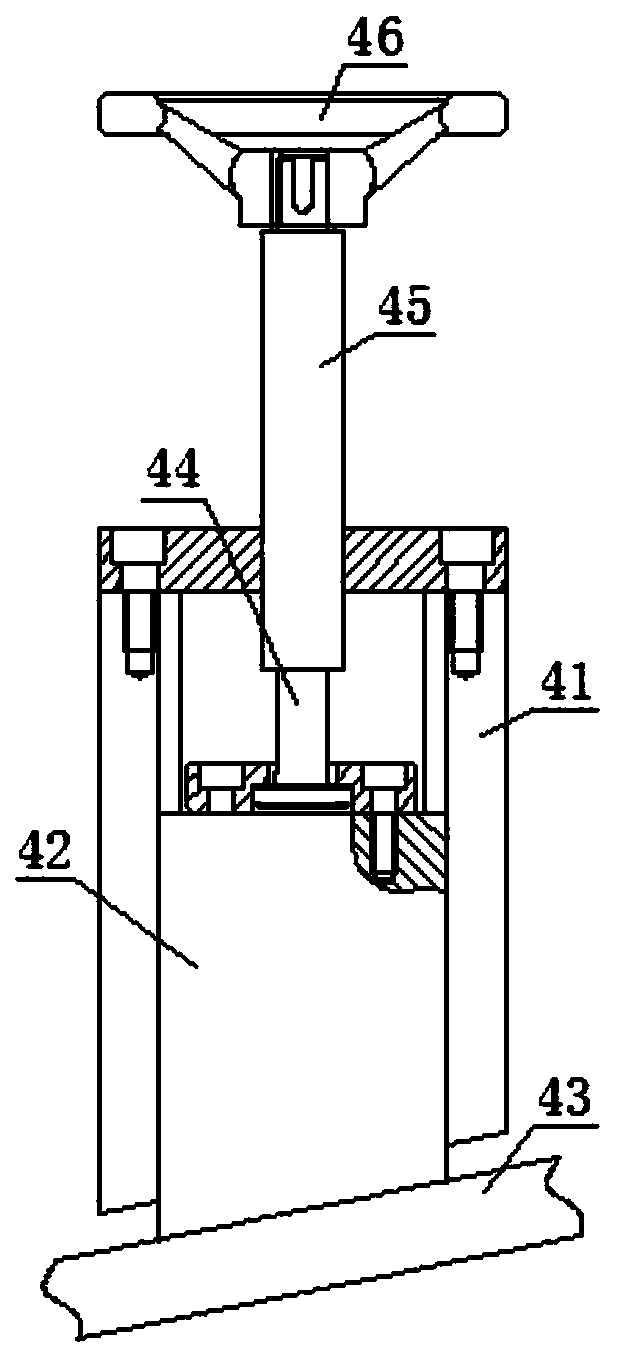

[0035] On the basis of Example 1, as figure 2 As shown, the booster device 4 includes a booster chute 41, and the booster chute 41 is fixed on the frame 1, and the booster chute 41 is provided with a booster slider 42, and the booster slider 42 is fixed There is a pressing plate 43, and the pressing plate 43 is arranged in the upper extruding conveyor belt 2, and the booster slide 42 is rotatably connected with a moving rod 44, and the booster moving rod 44 is externally threaded with a booster guide rod 45, and the booster guide rod 45 is fixed On the booster chute 41 , the other end of the booster moving rod 44 is fixed with a booster hand wheel 46 .

[0036] When the increasing handwheel 46 is turned, the pressurization moving rod 44 is stretched out or retracted in the pressurization guide rod 45 , thereby driving the lifting or lowering of the pressing plate 43 . The movement of the pressing plate 43 pushes the upper extruding conveyor belt 2 closer to or away from the ...

Embodiment 3

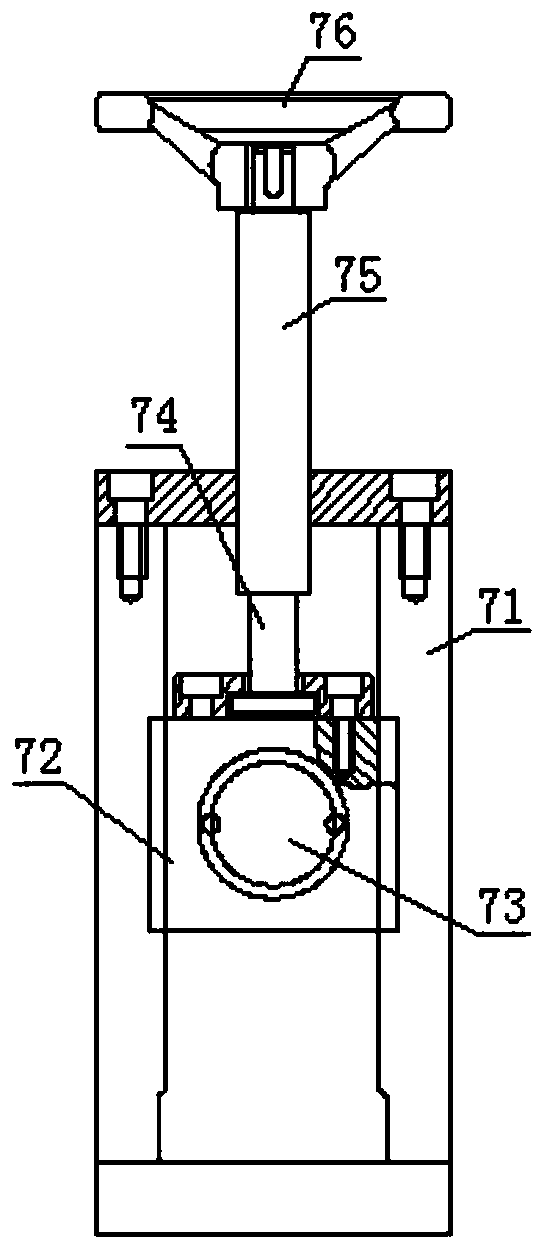

[0038] On the basis of Embodiment 1 or Embodiment 2, the material turning mechanism 6 includes a material turning motor 61, the material turning motor 61 is fixed on the frame 1, and the output shaft of the material turning motor 61 is connected with a material turning roller 62. The material turning roller 62 is installed on the frame 1 through the bearing, the turning material turning roller 62 is located above the conveying section, and a number of turning material turning plates 63 are arranged on the turning material turning roller 62 .

[0039] When the material turning motor 61 drives the turning roller 62 to rotate, the turning plate 63 on the turning roller 62 can turn the raw materials of pickled dishes, thereby breaking up the raw materials in pieces.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com