Method for controlling thermal insulation after lifting of electric kettle

A control method and technology for an electric kettle, which are applied in the field of kettle lifting and heat preservation, can solve problems such as dry burning, fire danger, detection and judgment of electric kettles, and achieve the effects of preventing dry burning, avoiding damage or danger, and improving user experience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

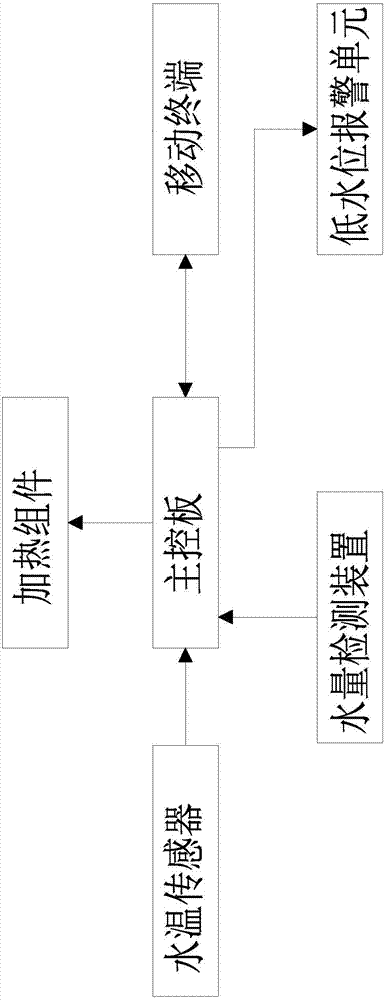

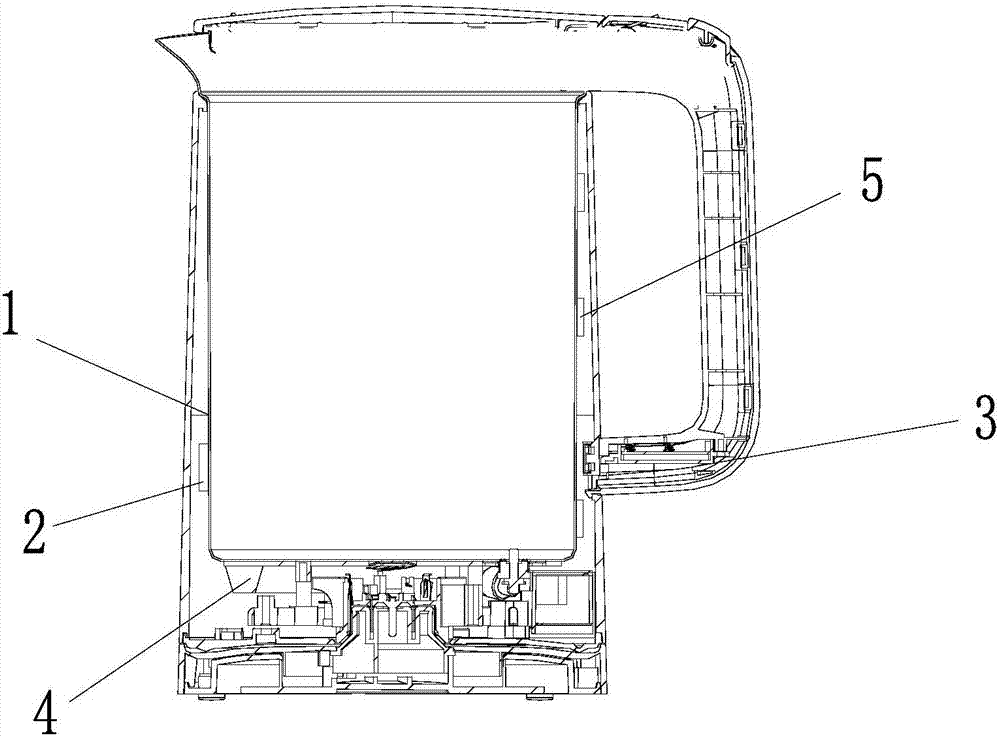

[0051] like Figure 1-2 As shown, a method for controlling heat preservation of an electric kettle is provided. The electric kettle is provided with a water temperature sensor 2 assembled in the kettle body 1, a water quantity detection device 5, a main control board 3 and a heating assembly 4, and the water temperature sensor 2 is arranged in the kettle body. Inside, the water temperature sensor 2 transmits the detected water temperature information in the pot to the main control board 3 , and the water volume detection device 5 transmits the detected water volume information to the main control board 3 .

[0052] According to the water temperature information and water quantity information, the main control board 3 controls the heating component 4 to heat and regulate the water temperature in the kettle only when the water quantity in the kettle is greater than the anti-dry threshold.

[0053] When the user lifts the kettle body 1 and puts it back after adding water in the h...

Embodiment 2

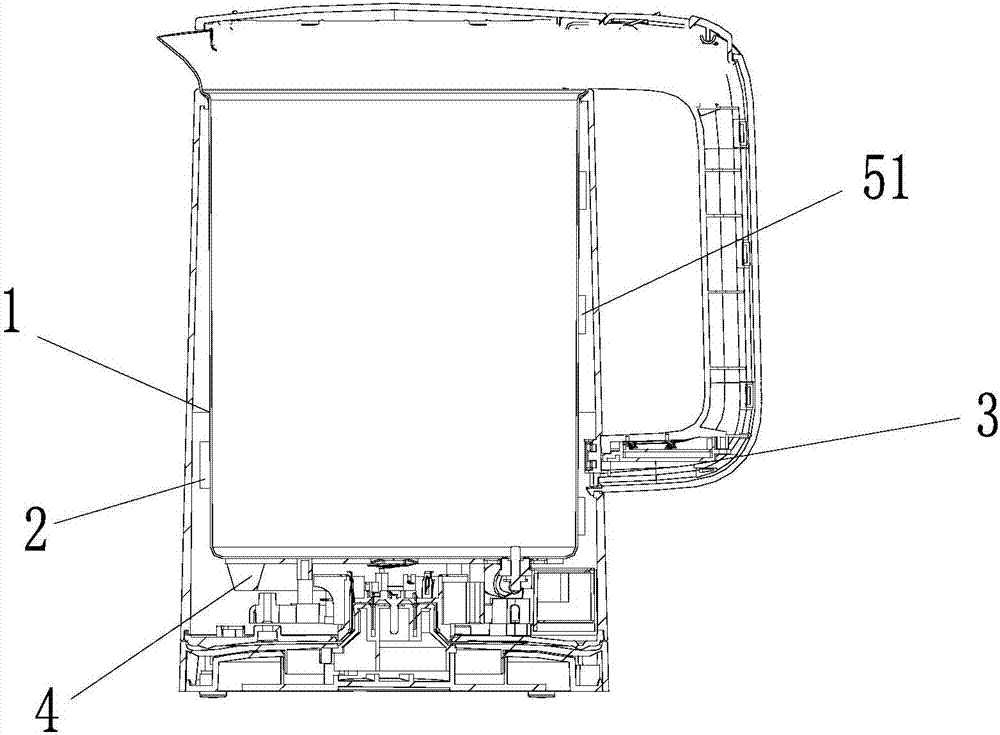

[0063] A method for controlling the heat preservation of an electric kettle, the other features are the same as in Embodiment 1, the difference is that: image 3 As shown, the water quantity detection device 5 includes a plurality of capacitive sensors 51 mounted on different water levels and a processor connected to the plurality of capacitive sensors 51, and the plurality of capacitive sensors 51 compare the detected capacitance with each capacitive sensor 51 Compare with the initially set capacitance;

[0064] If the capacitance detected by the sensor is greater than or equal to the corresponding capacitance initially set, it is determined that there is water at the water level;

[0065] If the capacitance detected by the sensor is less than the corresponding capacitance initially set, it is determined that there is no water at the water level;

[0066] The capacitive sensors 51 at multiple water levels send the detection results to the processor, and the processor compare...

Embodiment 3

[0069] A method for controlling the heat preservation of an electric kettle, the other features are the same as in Embodiment 1, the difference is that: Figure 4 As shown, the water quantity detection device 5 includes a plurality of water level probes 52 assembled at different water level heights and a processor connected to the plurality of water level probes 52, and the plurality of water level probes 52 compare the detected conductivity with each The capacitance initially set by the water level probe 52 is compared;

[0070] If the detected conductivity is greater than or equal to the initially set conductivity, it is determined that there is water at the water level;

[0071] If the detected conductivity is lower than the initially set conductivity, it is determined that there is no water at the water level.

[0072] It should be noted that in this embodiment, the water level probe 52 is used as the detection device to detect the water level information, and at the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com