A kind of oil release agent for grid casting of lead-acid battery

A lead-acid battery and release agent technology, applied in the direction of electrode carrier/collector, etc., can solve the problems of low viscosity, grid quality, drop rate of oily release agent, etc., to achieve low viscosity, The effect of improving production efficiency and improving fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] An oil-based release agent for grid casting of lead-acid batteries. The release agent consists of the following components in terms of mass percentage: rapeseed oil 98.85%, polymethyl methacrylate (viscosity of 1000-1300mm at 100°C 2 / s) 1.1%, organic molybdenum extreme pressure agent (Vanderbilt Company, L) 0.05%. Mix according to the above ratio, stir, heat and cool to form a release agent. The field trial product has good high-temperature spreadability and strong adhesion. After 31 minutes, the dropping speed drops, and manual tapping is required.

Embodiment 2

[0037] An oil-based release agent for grid casting of lead-acid batteries. The release agent is composed of the following components in terms of mass percentage: 98.60% rapeseed oil, polymethyl methacrylate (viscosity at 100°C is 1000-1300mm 2 / s) 1.1%, calcium petroleum sulfonate (total base number 22mgKOH / g) 0.25%, organic molybdenum extreme pressure agent (Vanderbilt Company, L) 0.05%. Mix according to the above ratio, stir, heat and cool to form a release agent. The dripping speed of the field trial product is uniform during the painting process, and the dripping speed drops after 48 minutes. Greatly reduces the frequency of manual knocking, reduces problems such as burrs and mold sticking caused by drop or uneven drop speed, effectively improves production efficiency and product quality, and is suitable for the production of continuous casting lead-calcium alloy grids .

Embodiment 3

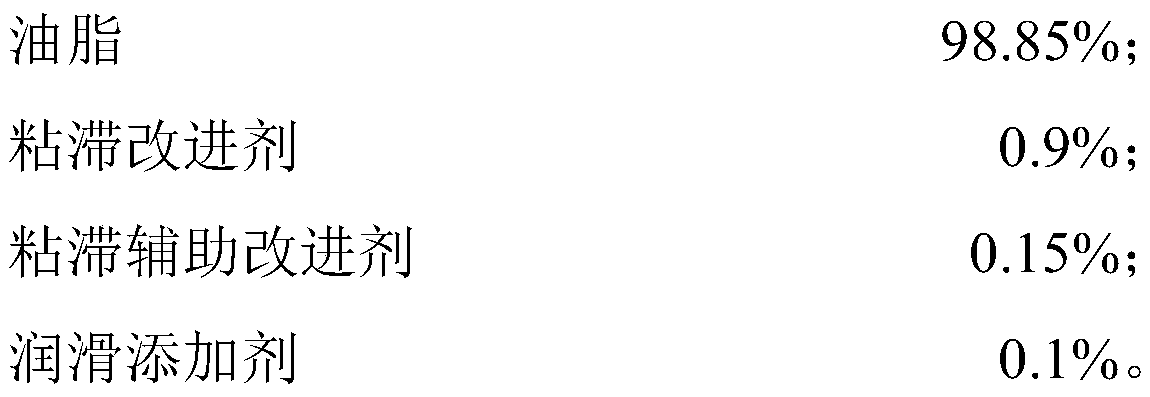

[0039] An oily release agent for the casting of lead-acid battery grids, the release agent consists of the following components in terms of mass percentage: trimethylolpropane oleate 98.85%, polymethyl methacrylate (100 °C viscosity 900~1100mm 2 / s) 0.9%, calcium petroleum sulfonate (total base number 72mgKOH / g) 0.15%, organic molybdenum extreme pressure agent (Vanderbilt Company, L) 0.1%. Mix according to the above ratio, stir, heat and cool to form a release agent. The dripping speed of the field trial product is uniform during the painting process, and the dripping speed drops after 51 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com