Polishing structure for inner surfaces of bent pipe pieces

A technology for inner surface and pipe bending, applied in the field of inner surface treatment of pipe bending, can solve problems such as sharp reduction in service life, and achieve the effect of prolonging service life, improving practicability and increasing rotation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

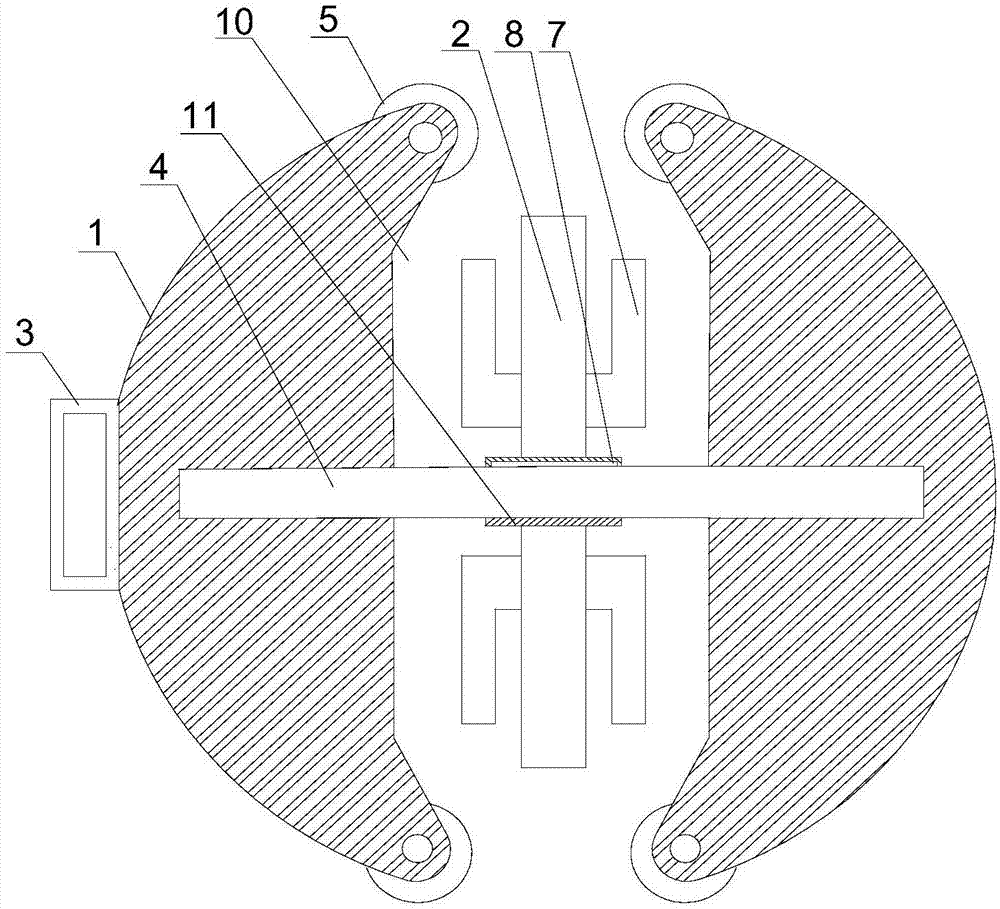

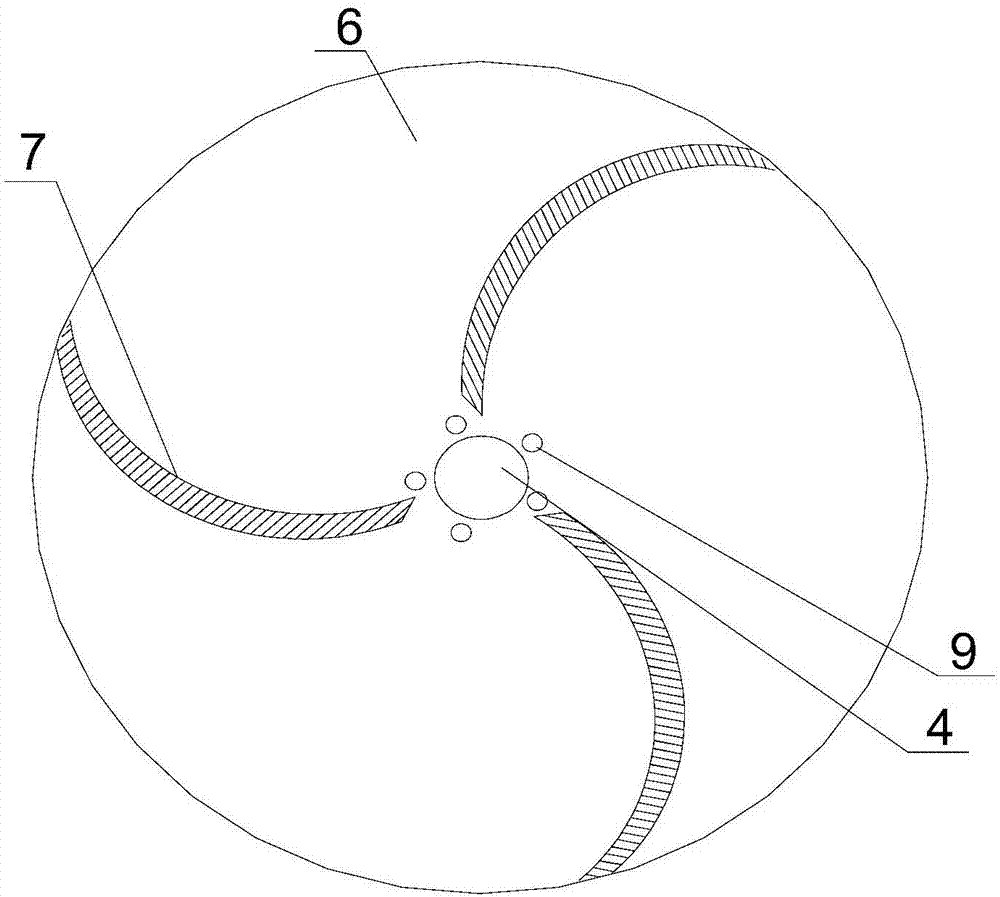

[0024] Such as figure 1 and figure 2 As shown, this embodiment includes two semi-spherical bodies 1 oppositely arranged and a rotating shaft 4 for connecting the two semi-spherical bodies 1, a sleeve 11 is provided in the middle of the rotating shaft 4, and a sleeve 11 is arranged in the middle along the axis of the rotating shaft 4 The outer wall of the sleeve 11 is provided with a strip-shaped protrusion 8, and the inner peripheral wall of the sleeve 11 is provided with a groove that cooperates with the protrusion 8, and the protrusion 8 can rotate freely in the groove around the axis of the rotating shaft 4. In the sleeve 11 A runner 2 is installed on the outer peripheral wall, the runner 2 includes a body 6, the body 6 is arranged on the sleeve 11, a plurality of blades 7 are arranged on both sides of the body 6, two adjacent blades 7 form a vane groove, and rollers 5 are installed at the ends of the upper and lower ends of the semi-spherical body 1 . Aiming at the defe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com