Method for machining angle groove of graphite distribution ring through radial drilling machine

A technology of radial drilling machine and distribution ring, which is applied in the direction of working accessories, stone processing tools, stone processing equipment, etc., can solve the problems of complex process and large error, and achieve the effect of simple operation, small angle error and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

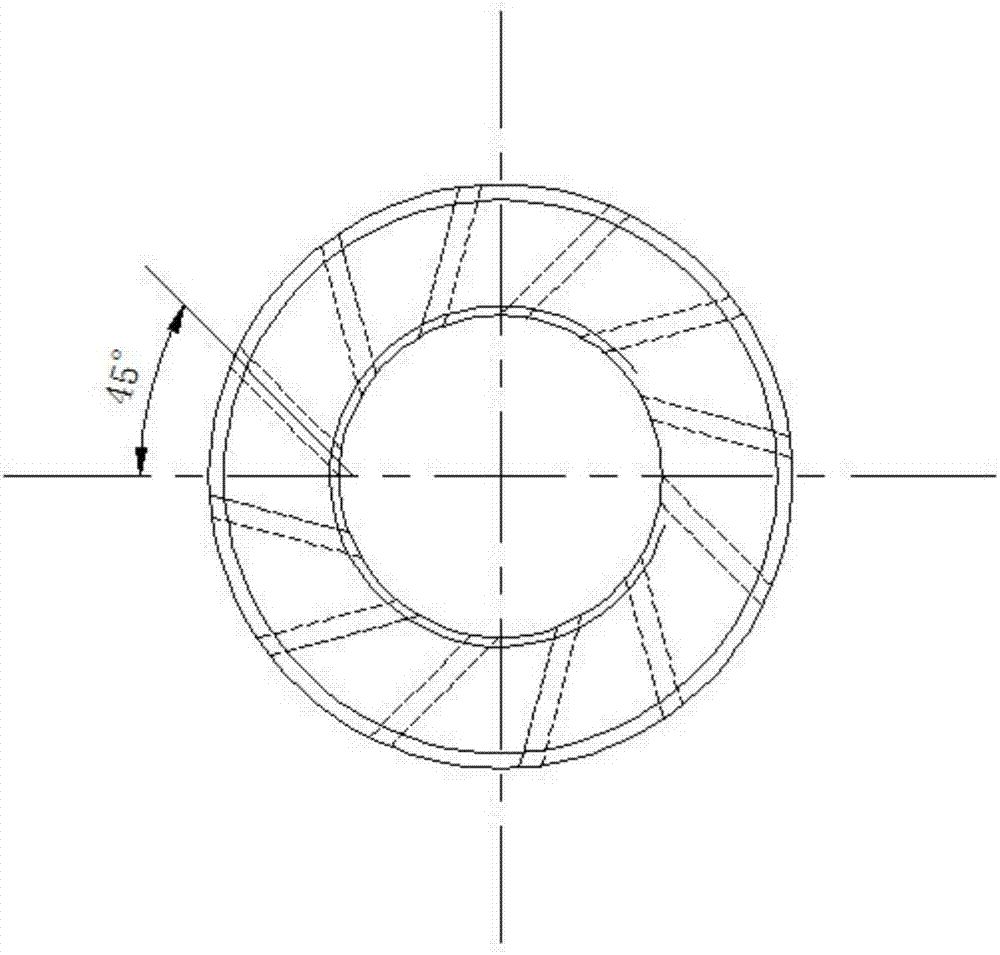

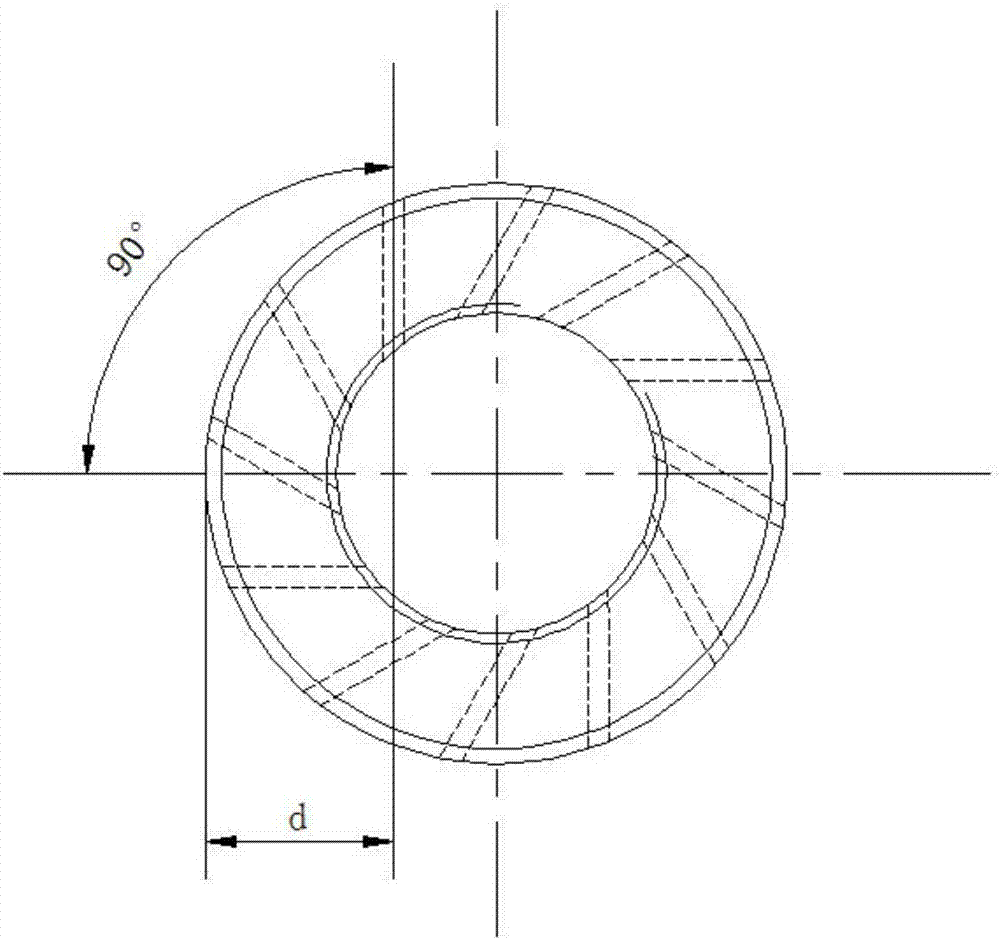

[0015] Such as figure 1 , 2 As shown, a method for processing graphite distribution ring angle grooves by a radial drilling machine in the present embodiment, wherein: comprises the following steps:

[0016] 1) Rotate the graph of the graphite distribution ring to be slotted 45 degrees clockwise along the center of the circle through the drawing software;

[0017] 2) Mark the distance d between the angle groove perpendicular to the axis and the outer edge of the distribution ring in the drawing software;

[0018] 3) Clamp the distribution ring into the dividing head, and adjust the distance between the milling cutter and the distribution ring outer edge according to the distance d between the angle groove perpendicular to the axis in step 2) and the outer edge of the distribution ring;

[0019] 4) Start the radial drilling machine to mill g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com