A method for testing lens focal length without mechanical movement

A lens focal length and testing method technology, which is applied in the testing of machine/structural components, optical instrument testing, optical performance testing, etc., can solve the problems of difficult adjustment of the lens focal length testing device, low measurement accuracy, high cost, etc., and achieve simplification. The process of measuring the focal length of the lens, the effect of high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Principle of the present invention is:

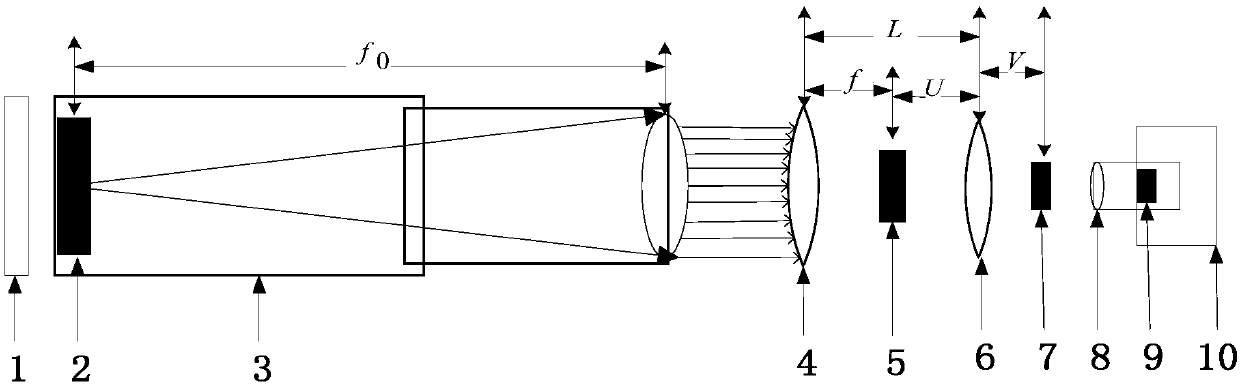

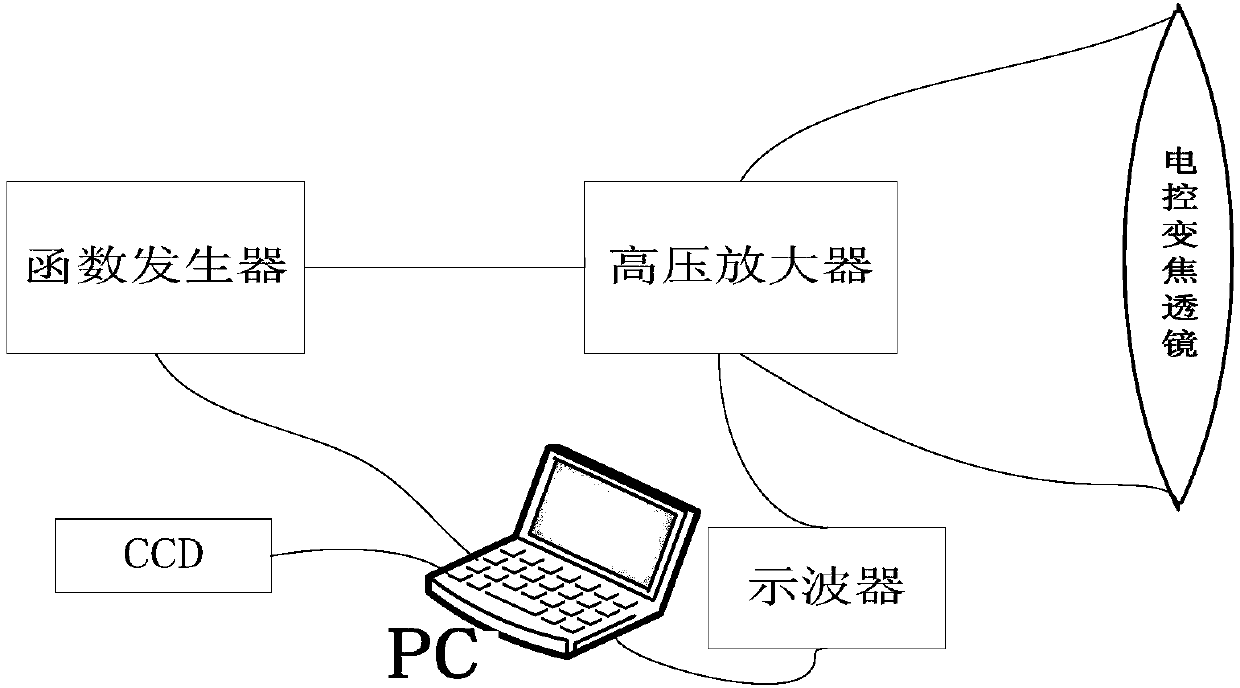

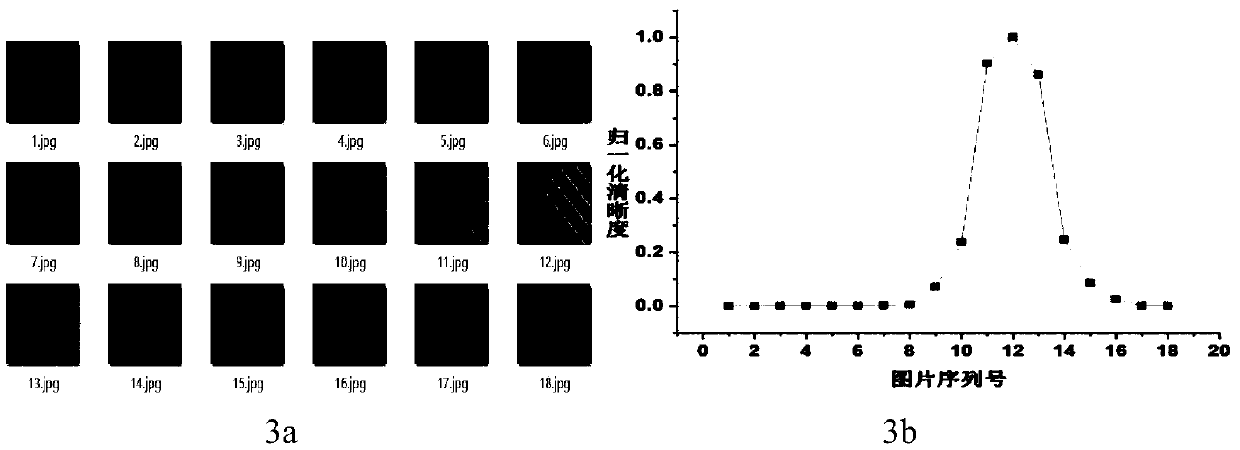

[0040] Such as figure 1 As shown, the size of Ronchi grating 2 is y 0 , image 5 at the focal plane of the lens to be tested through the collimator 3 and the lens to be tested 4, and the size of the image of the Ronchi grating through the lens to be tested is y 1 , and then through the electronically controlled zoom lens 6 to image 7, the size of the image through the zoom lens is y 2 , and finally form an image on the CCD10 through the microscope objective lens 8, and the size of the image 9 formed on the CCD through the microscope objective lens is y 3 . When the focal length of the lens to be tested changes, a clear image can be obtained on the CCD by adjusting the driving voltage of the electronically controlled zoom lens. The focal length of the collimator is f 0 , the focal length of the lens to be tested is f, and the focal length of the electronically controlled zoom lens is f 1 , the distance between the lens to be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com