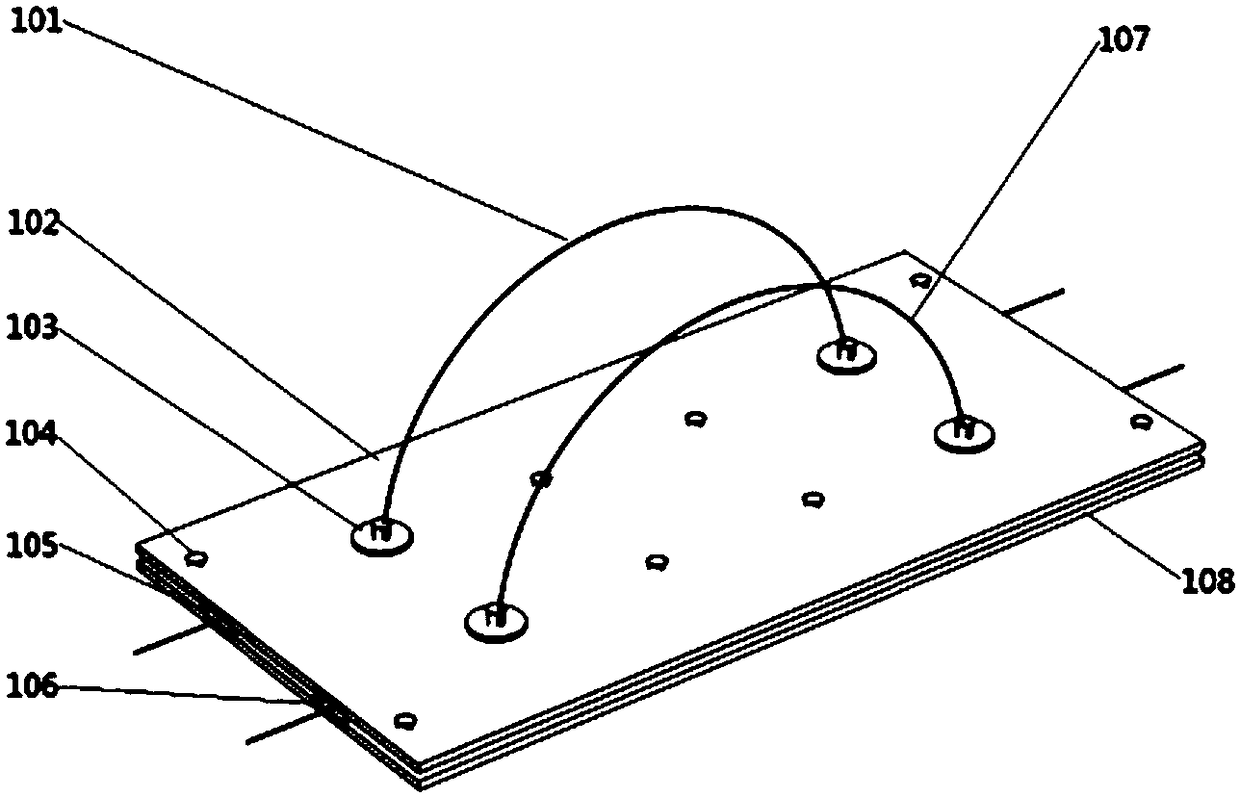

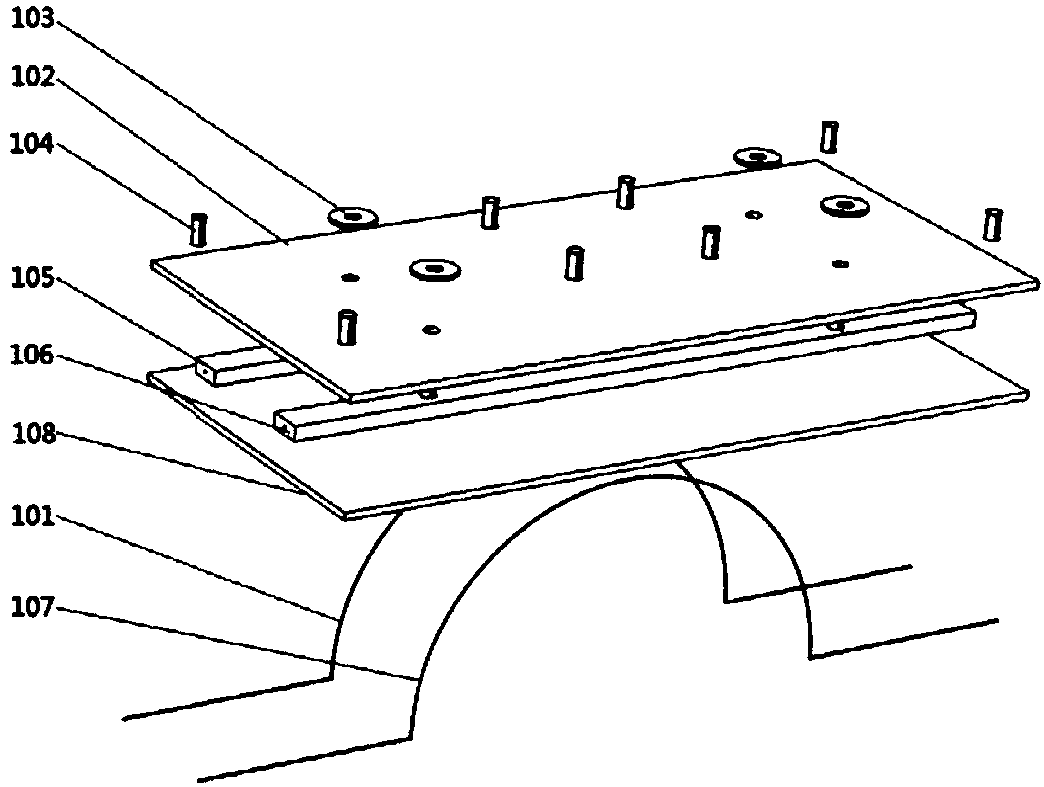

Near space electrodynamic patch

A near-space, electric power technology, applied in the direction of motor vehicles, lighter-than-air aircraft, rigid spacecraft, etc., can solve the problems of high thrust lower limit, loud noise, and inability to actively control, etc., and achieve the requirements of no-rotational torque balance and infrared visibility Low, simple design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0025] Embodiment 2 is attached Figure 4 As shown, the material of each part is the same as that of Embodiment 1, but the embodiment 2 increases the cathode wire 401 and the anode wire 407 of the inner ring in structure; The bottom of the base 406 penetrates and passes through from their other side; the insulating rivets passing through the cathode base 405 and the anode base 406 are reduced to one, so the fixing is also increased between the cathode base 405 and the anode base 406 Insulated rivets 404 for location.

[0026] In Embodiment 2, the number of cathode wires 401 and anode wires 407 in the inner ring can be determined according to the size of the electrodynamic patch, and a distance of 1 cm to 2 cm is usually maintained between the inner and outer rings of the cathode wire 401 or anode wire 407; The number of loops may be less than or equal to the number of loops in the anode wire 407 .

[0027] The connection mode of embodiment 2 is the same as that of embodiment...

Embodiment 3

[0028] Embodiment 3 is attached Figure 5 As shown, the materials of each component are the same as in Embodiment 1, the cathode wire 501 and the anode wire 507 penetrate through the bottom of the lower insulating layer 508, pass through the cathode base 504 and the anode base 505, and pass through the upper insulating layer 506, Keep vertical to the surface of the upper insulating layer, and the height on the surface of the upper insulating layer is 1mm to 3cm; there are no lead holes on the left and right sides of the cathode base 504 and the anode base 505, but the top circular tube vertically penetrates the bottom to form Through holes: Insulation rivets 503 are located between the round tubes of the cathode base 504 and the anode base 505 except that the four corners of the patch remain unchanged.

[0029] The connection mode of embodiment 3 is the same as that of embodiment 1, the anode wire 507 is connected to the output terminal of the high voltage power supply, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com