Multilayer separate injection experiment system and method for carrying out indoor experiment thereof

An experimental device and a technology for dressing, which is applied in the field of experimental devices, can solve problems such as the inability to realize multi-layer dispensing requirements, troublesome use and operation, etc., and achieve the effect of simple structure, convenient operation, and meeting experimental requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing, the present invention will be further described:

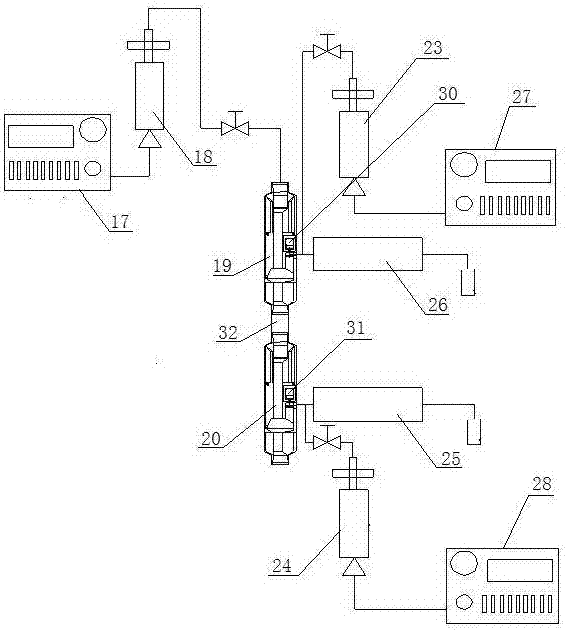

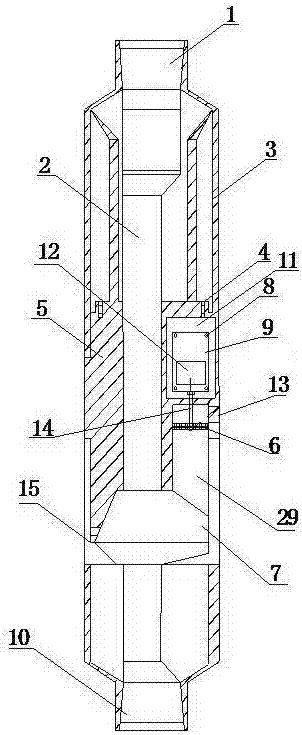

[0021] combine figure 1 , figure 2 , image 3 As shown, this multi-layer dispensing experimental device includes a plurality of advection pumps, a plurality of piston containers, wherein the first advection pump 17 is connected to the first piston container 18, the first piston container 18 holds the polymer solution, and the first piston container 18 Connected to the upper joint 1 of the first chemical flooding distributor 19 through a pipeline, the first chemical flooding distributor 19 is connected to the second chemical flooding distributor 20 through the connecting cylinder 32; the liquid outlet of the first chemical flooding distributor 19 The hole 13 is connected to the inlet end of the first sand filling pipe 26, the second advection pump 27 is connected to the second piston container 23, the second piston container 23 is connected to the inlet end of the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com