An electric heating tube pickling equipment

A technology of pickling equipment and electric heating tube, which is applied in the field of electric heating tube pickling equipment, can solve the problems of waste of pickling liquid and unavoidable dust entering the pickling container

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

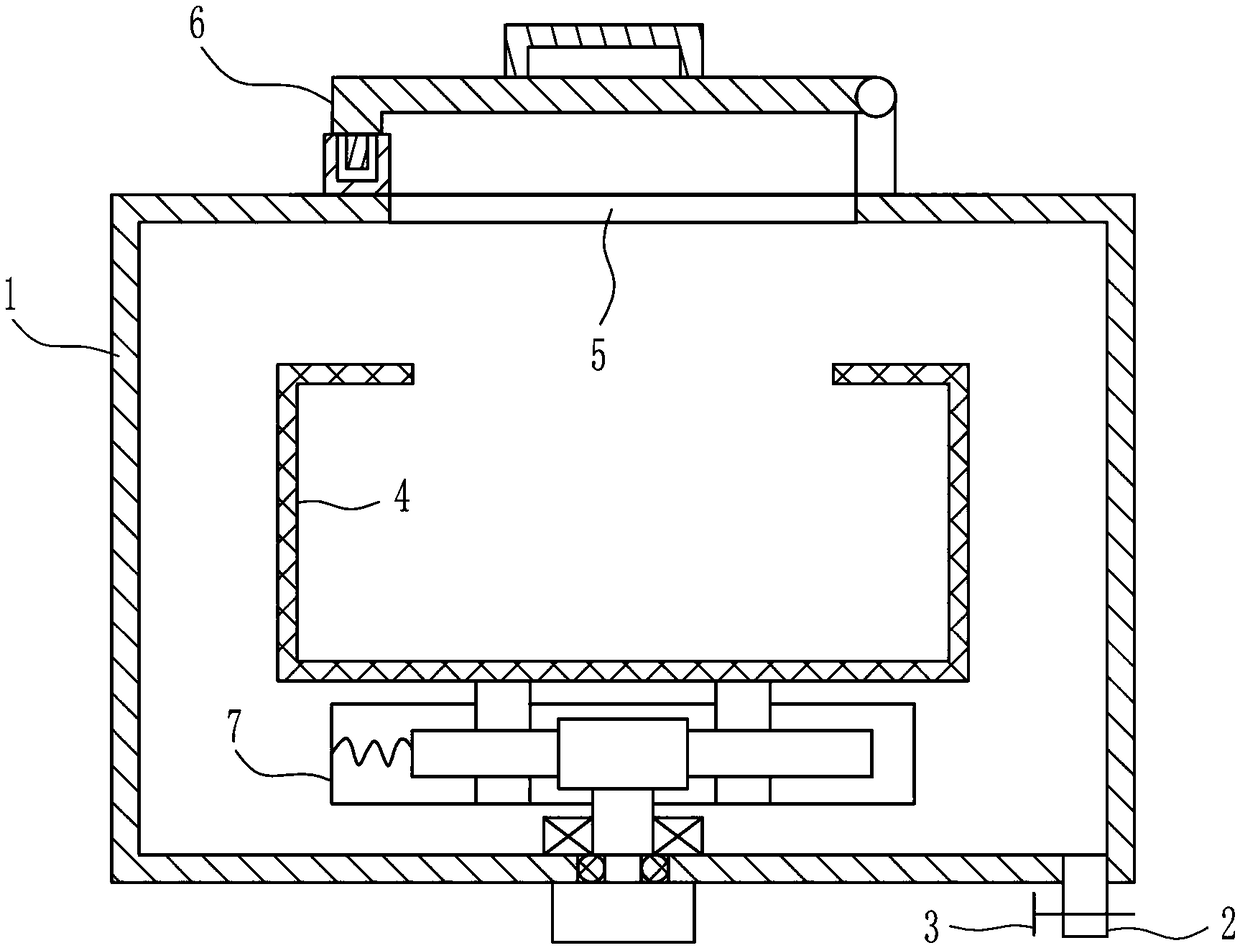

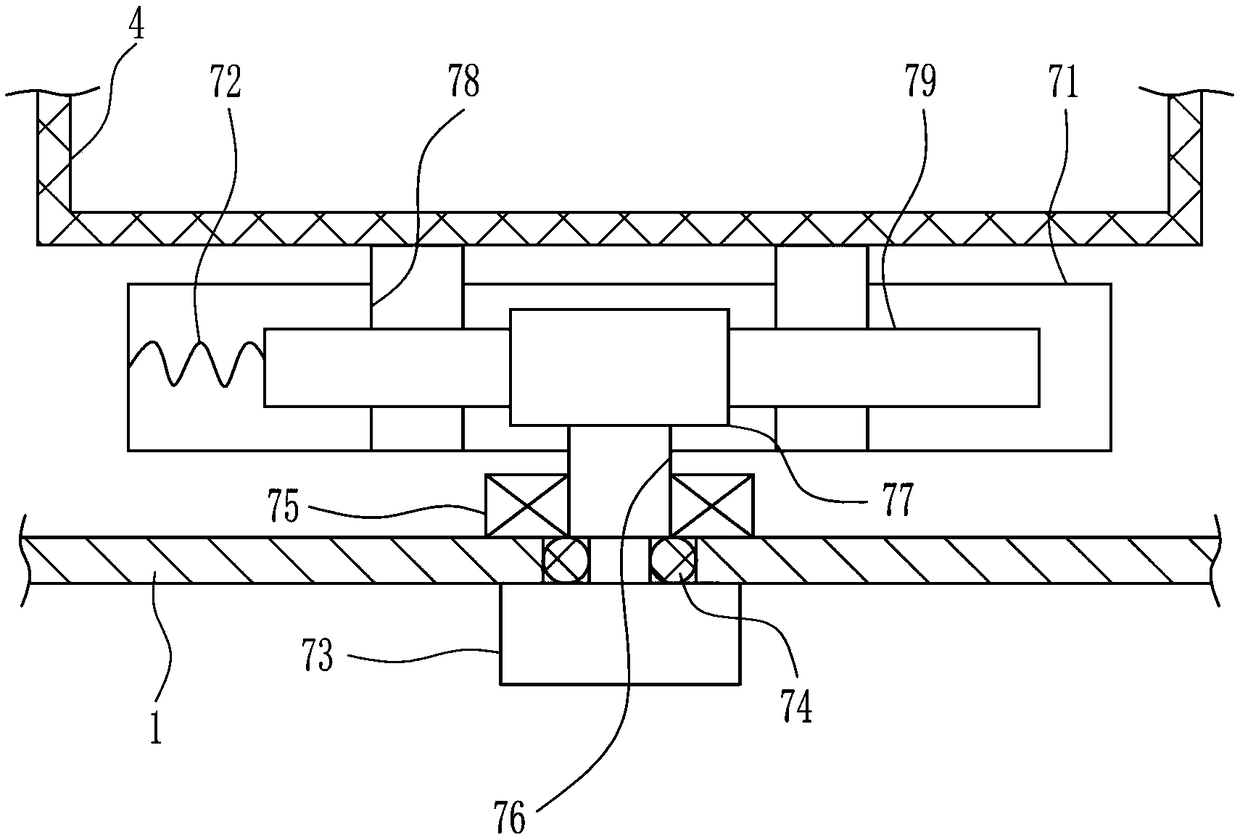

[0034] An electric heating tube pickling equipment, such as Figure 1-5As shown, it includes a pickling box 1, a first liquid outlet pipe 2, a first valve 3, a screen frame 4, a cover tightening mechanism 6 and a moving mechanism 7, and the right part of the inner bottom wall of the pickling box 1 is connected with the first liquid outlet Pipe 2, the first liquid outlet pipe 2 is provided with a first valve 3, a moving mechanism 7 is arranged in the middle of the inner bottom of the pickling tank 1, and a screen frame 4 is connected to the moving mechanism 7, and a valve is opened in the middle of the inner top wall of the pickling tank 1. The first through hole 5 and the top of the pickling box 1 are provided with a capping mechanism 6 .

Embodiment 2

[0036] An electric heating tube pickling equipment, such as Figure 1-5 As shown, it includes a pickling box 1, a first liquid outlet pipe 2, a first valve 3, a screen frame 4, a cover tightening mechanism 6 and a moving mechanism 7, and the right part of the inner bottom wall of the pickling box 1 is connected with the first liquid outlet Pipe 2, the first liquid outlet pipe 2 is provided with a first valve 3, a moving mechanism 7 is arranged in the middle of the inner bottom of the pickling tank 1, and a screen frame 4 is connected to the moving mechanism 7, and a valve is opened in the middle of the inner top wall of the pickling tank 1. The first through hole 5 and the top of the pickling box 1 are provided with a capping mechanism 6 .

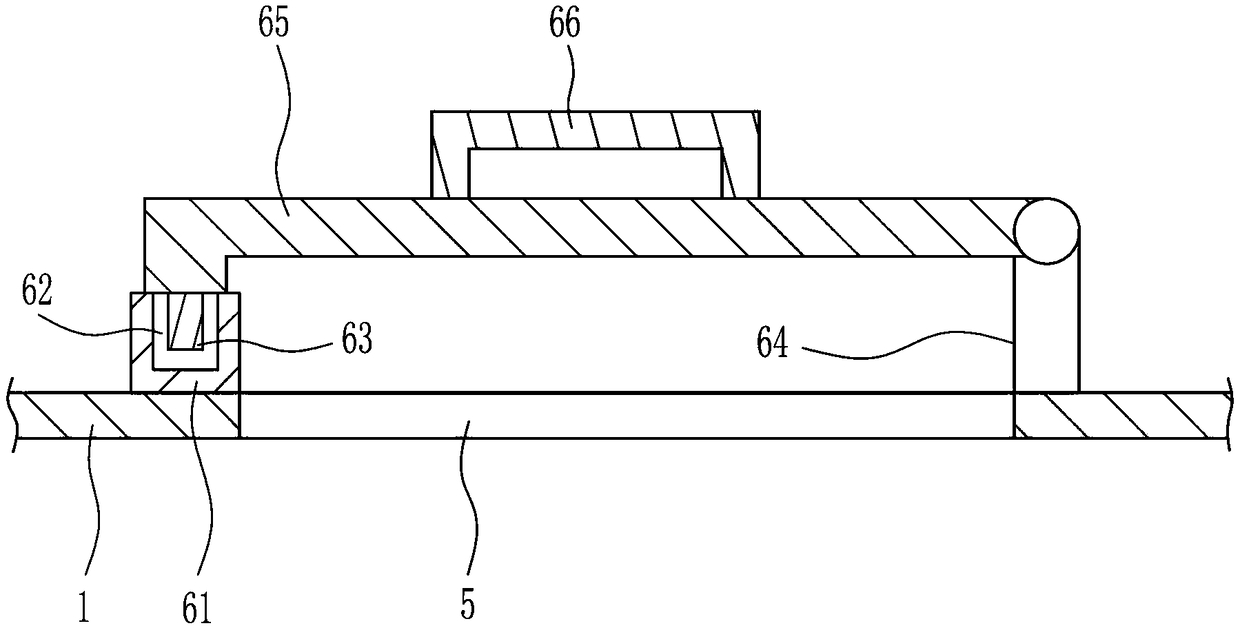

[0037] The capping mechanism 6 includes a fixed block 61, a clamping block 63, a fixed rod 64, a cover plate 65 and a handle 66. The left side of the top of the pickling box 1 is connected with a fixed block 61, and the fixed block 61 has ...

Embodiment 3

[0039] An electric heating tube pickling equipment, such as Figure 1-5 As shown, it includes a pickling box 1, a first liquid outlet pipe 2, a first valve 3, a screen frame 4, a cover tightening mechanism 6 and a moving mechanism 7, and the right part of the inner bottom wall of the pickling box 1 is connected with the first liquid outlet Pipe 2, the first liquid outlet pipe 2 is provided with a first valve 3, a moving mechanism 7 is arranged in the middle of the inner bottom of the pickling tank 1, and a screen frame 4 is connected to the moving mechanism 7, and a valve is opened in the middle of the inner top wall of the pickling tank 1. The first through hole 5 and the top of the pickling box 1 are provided with a capping mechanism 6 .

[0040] The capping mechanism 6 includes a fixed block 61, a clamping block 63, a fixed rod 64, a cover plate 65 and a handle 66. The left side of the top of the pickling box 1 is connected with a fixed block 61, and the fixed block 61 has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com