A composite steel box girder and its construction method

A construction method and technology of steel box girder, applied in the field of bridge structure, can solve the problems of increasing hoisting weight, complicated on-site operation, large width, etc., and achieve the effect of ensuring dynamic stability, facilitating hoisting operation, and increasing frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

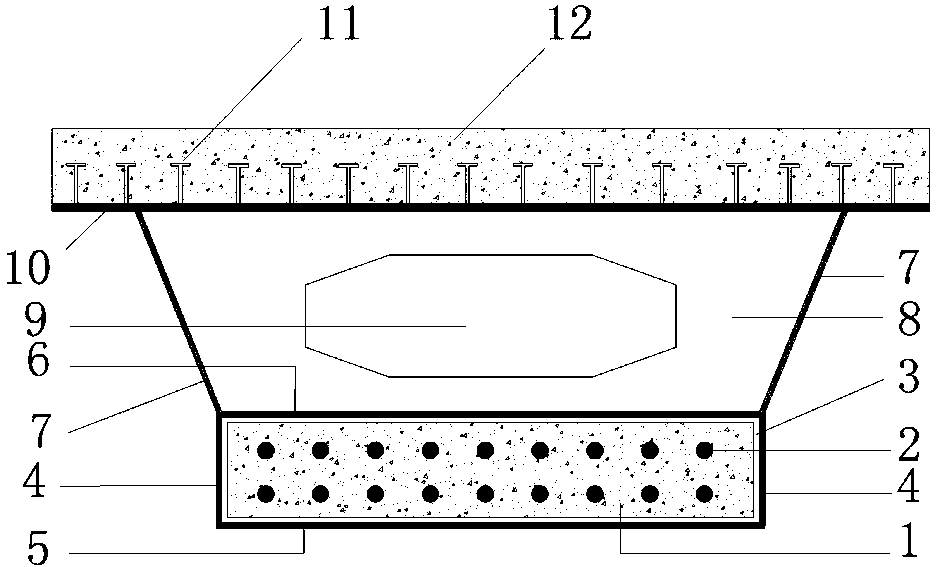

Embodiment 1

[0036] For the schematic diagram corresponding to this embodiment, see Figure 5. This embodiment is applied to the manufacture and installation of high-speed railway bridges. The steel box in the present invention includes an upper steel box and a lower steel box. The upper steel box is composed of the upper steel box web (7), the two steel box partitions (6) and the upper flange plate (10). There is a manhole (9) in the middle of the steel box transverse partition (8); the lower steel box is composed of the lower steel box web (4), two steel box partitions (6) and the lower steel box bottom plate (5), the lower steel box A prestressed concrete slab (1) is installed inside, a bonding layer (3) is arranged between the two, and prestressed tendons (2) are arranged inside the prestressed concrete slab (1). A prefabricated concrete top plate (12) is connected to the upper flange plate (10), and the two are connected through cluster shear studs (14) welded on the upper surface ...

Embodiment 2

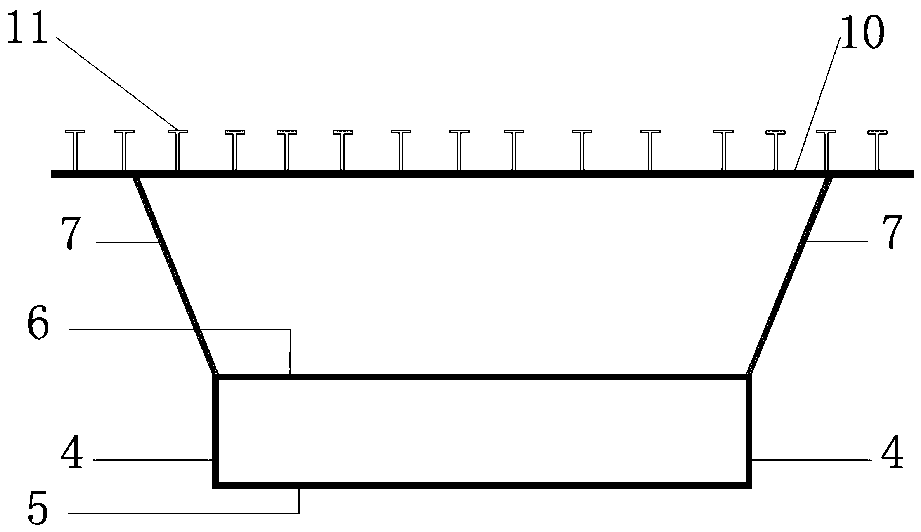

[0045] For the schematic diagram corresponding to this embodiment, see Figure 4 , applied to urban bridges, the number of bridge spans in the corresponding project is relatively small. This embodiment is a modification of Embodiment 1. The concrete roof (12) is constructed by the cast-in-place method, and the upper surface of the upper flange (10) is welded with stud connectors (11). Correspondingly, the step (b) in the construction method is omitted, and the installation of the prefabricated concrete roof (12) in the step (d) is replaced by on-site pouring. After pouring, it should be maintained for 7 days according to the construction requirements before the next step of construction can be carried out. The manufacture of the upper steel box is the same as the conventional steel box girder, and U-shaped channel steel members are welded under the bottom plate to form the lower steel box. This embodiment reduces the workload of prefabrication and installation, but needs to ...

Embodiment 3

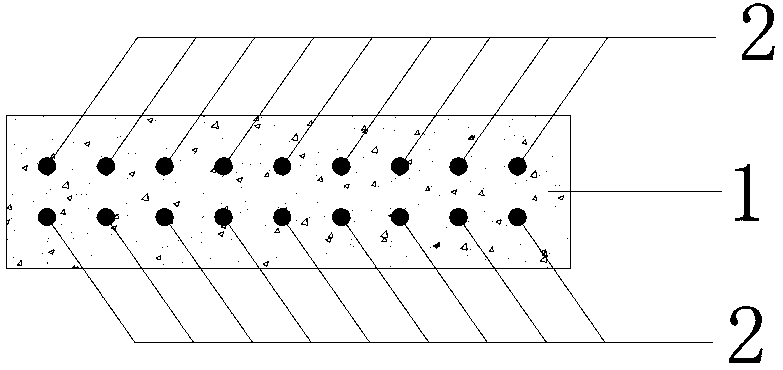

[0047] The schematic diagram corresponding to this embodiment is shown in figure 1 , figure 2 and image 3 . This embodiment is a modification of Embodiment 2. Mainly because the bottom of the fastening bolt (13) is outside the lower surface of the lower steel box floor (5), that is, the outer side of the steel box, which affects the appearance, it is canceled, thereby simplifying prefabrication and on-site construction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com