Construction method of prestressed pipe pile in sand bed or pebble bed

A technology of prestressed pipe piles and pebble layers, applied in sheet pile walls, buildings, infrastructure projects, etc., can solve problems such as weak resistance to horizontal shear force, achieve strong lateral slip resistance, good quality stability, increased The effect of bending resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

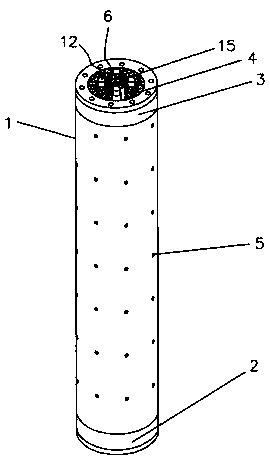

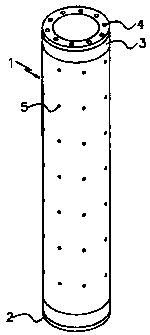

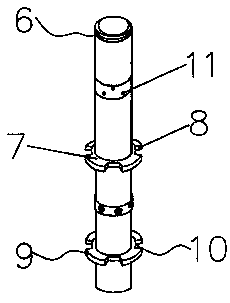

[0029] The present invention is described in detail below in conjunction with accompanying drawing:

[0030] A prestressed pipe pile in a sand layer or pebble layer, including a weak foundation pit in a sandy soil layer, a first pipe pile section 1, a first section grouting pipe 6 and a steel rod 12, and the first section pipe pile Slurry diffusion holes 5 are processed on the pipe wall of section 1, and the slurry diffusion holes 5 are arranged on the pipe wall in a quincunx shape; the upper sleeve chuck 7 and the lower sleeve chuck are socketed on the first section grouting pipe 6 Disk 9, on the outer circle of the sleeve chuck 7 at the top, there are steel bar upper clamping gaps 8 at equal intervals on the outer circle, and on the outer circle of the lower sleeve chuck 9, there are steel rod lower clamping joints at equal intervals on the outer circle. Gap 10, a steel rod 12 is clamped between the clamping gap 8 on the steel rod and the clamping gap 10 under the steel rod,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com