Dry ice freezing treating and conveying line

A conveying line and dry ice technology, applied in the field of processing lines, can solve the problems of high cost, insignificant cooling effect, and difficulty in improving the freezing processing speed, etc., and achieve the effect of reasonable structure, fast and thorough dry ice freezing processing without dead ends.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

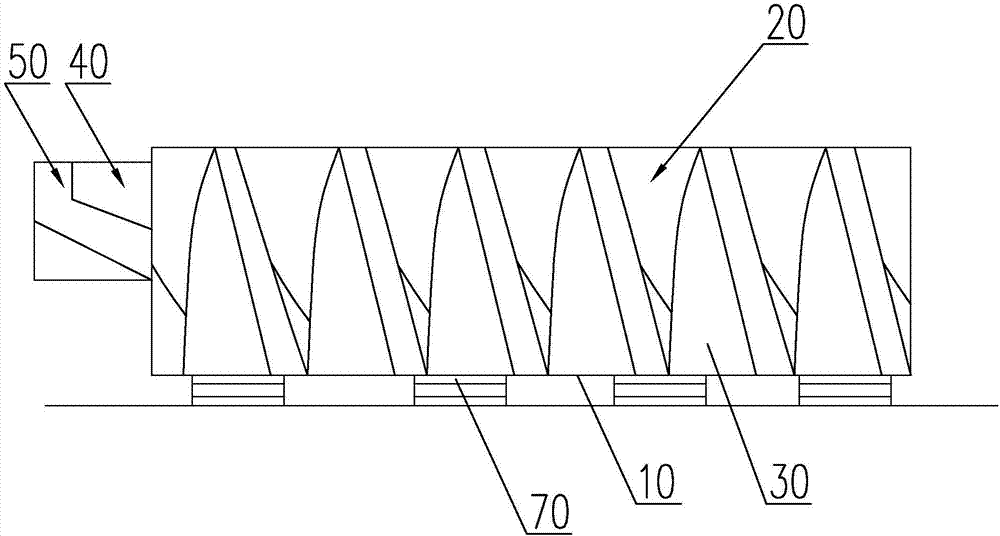

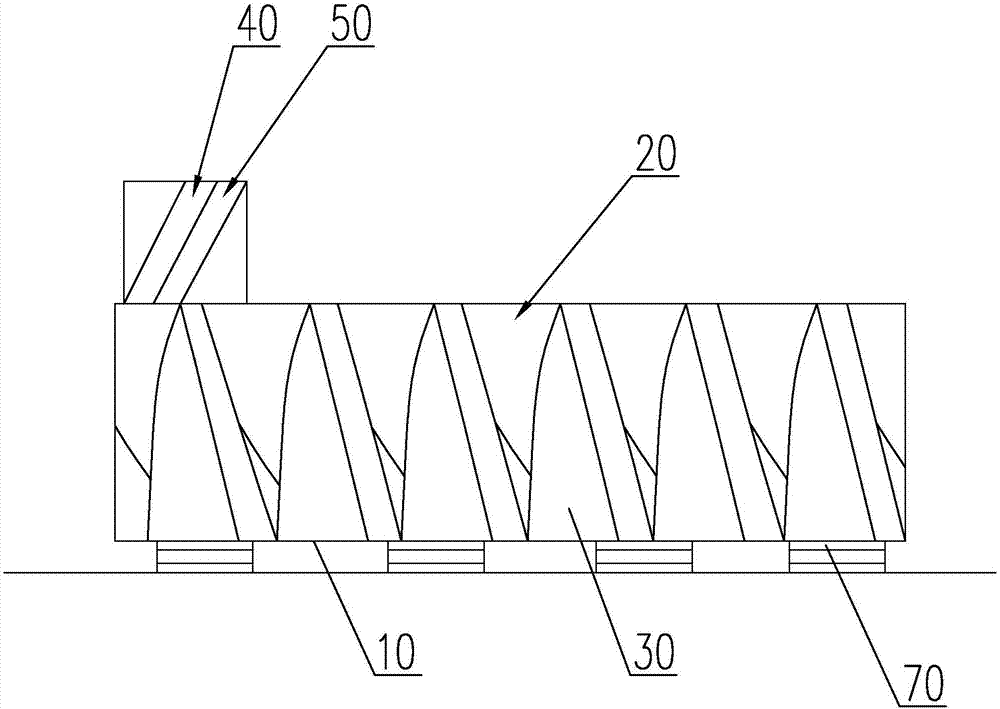

[0022] A dry ice freezing processing conveying line, such as Figure 1 to Figure 5 As shown, it includes a helical rotatable body and a rotating drive body for driving the helical rotatable body to rotate; the helical rotatable body is determined according to its rotation direction at one end as the beginning of the helical rotation, and at the other end as the end of the helical rotation; It includes a material feed port and a dry ice feed port. The material feed port and the dry ice feed port can supply some materials and some dry ice to enter and mix on the spiral rotating body through the beginning of the spiral rotation; There is also a dry ice screening device on the rotating body, which can screen the dry ice during the rotation of the spiral rotating body so that it is always on the spiral rotating body and cannot be transported to the end of the spiral rotation synchronously with the material.

[0023] In Embodiment 1 of the present invention, the helically rotatable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com