Lifting sun-drying frame with loop-chain supporting arms

A technology of supporting arms and lifting racks, applied in the field of lifting drying racks, can solve the problems of complex structure of lifting racks, affecting the use function, and high folding height, achieving outstanding anti-interference performance, easy cleaning, and overcoming the effects of unbalanced loads.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

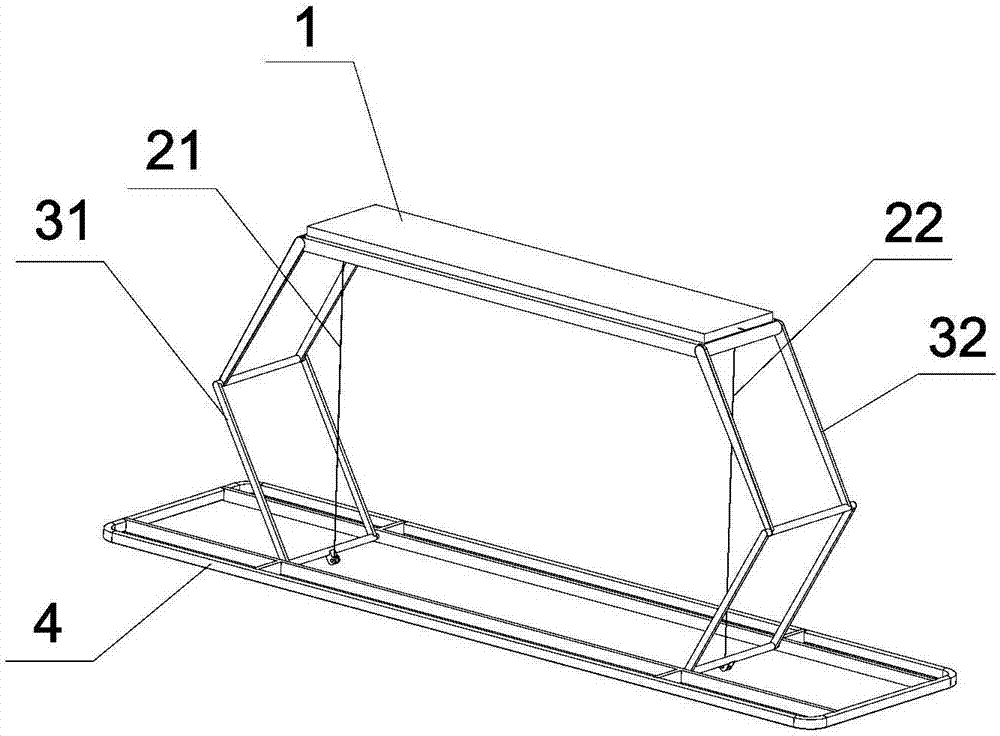

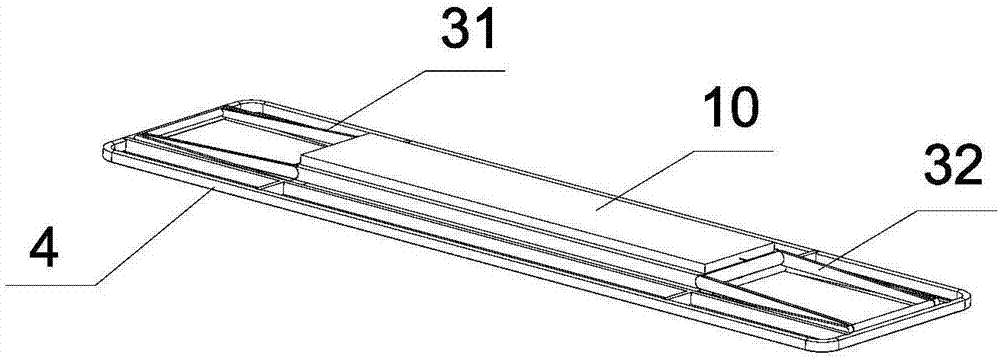

[0032] Embodiment 1, with reference to attached figure 1 , 2 , 3, 4:

[0033] The elevating drying rack with chain support arms provided by the present invention comprises a top mounting frame 1, and the top mounting frame 1 is fixed on the ceiling through a suspension mechanism. The top mounting frame can be a whole mounting frame or shell, or it can be divided into two sections. Because it is fixed on the ceiling, the position cannot change between the two sections. Therefore, these two sections can still be regarded as forming a top mounting bracket and form a link in the chain link structure described below.

[0034] The drying frame also includes a foldable lifting frame, and the lifting frame includes a left chain support arm 31 , a right chain support arm 32 and a bottom frame 4 . The left chain support arm 31 and the right chain support arm 32 are as symmetrical as possible, and the left chain support arm 31 and the right chain support arm 32 both include an upper a...

Embodiment 2

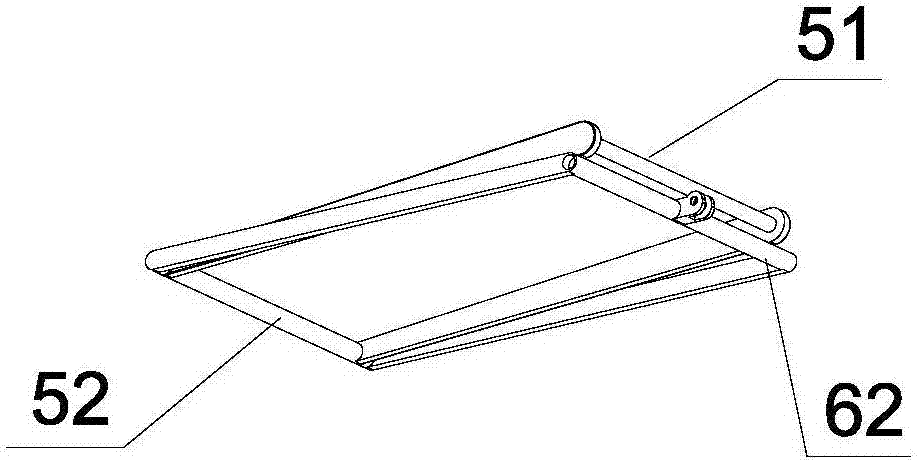

[0044] Embodiment 2, with reference to Figure 5-8 , 9a, 9b, 10:

[0045] In this embodiment, the lower part of the lower arm frame 6 is hinged to the bottom frame 4, and the lower frame bar of the lower arm frame has a sunken part 63, which can accommodate the upper arm frame 5 when folded and reduce the thickness in the folded state. Other parts of this embodiment are the same as Embodiment 1, in Figure 5-8 , 9a, 9b, 10, the reference numerals and Figure 1-4 The same means the same.

Embodiment 3

[0046] Embodiment 3, with reference to Figure 11 , 12a , 12b, 13a, 13b:

[0047] This embodiment mainly introduces the connection structure between the stay rope and the lifting frame. Such as Figure 11 As shown, the middle part of the lower frame bar of the lower arm frame is provided with a connecting mechanism 70 connected with the rotating shaft 7, and the connecting mechanism 70 with the rotating shaft 7 in the left part is connected with the left pull cord 21, and in the right part The connecting mechanism 70 with the rotating shaft 7 is connected with the right stay cord 22 . The force point of the connecting mechanism with a rotating shaft and the pull rope is located on one side of the hinge axis of the lower arm frame and the bottom frame, and is on the opposite side to the bending direction of the side chain support arm, so as to provide side support when the pull rope is pulled up. The partial force makes this side link chain support arm easy to fold.

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com