Tunnel surrounding rock deformation distributed optical fiber monitoring method and device based on pipe-shed support

A technology of distributed optical fiber and surrounding rock deformation, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of lack of perfect distributed optical fiber and monitoring technology, and achieve simple data collection and extraction, and low monitoring cost. Low, favorable effect on data collection, transmission and construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

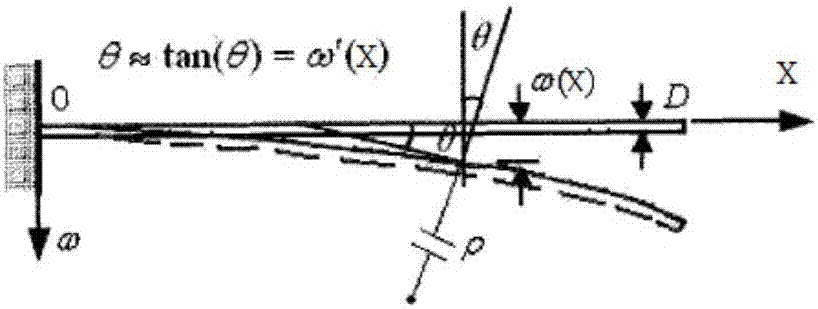

[0053] according to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 It can be seen that a distributed optical fiber monitoring method for tunnel surrounding rock deformation based on pipe shed support specifically includes the following steps:

[0054] Step 1. Use the pipe shed drilling rig 10 to drill holes from the guide pipe 2 and the steel pipe 4 to follow up. Drill the monitoring hole 3 and lay the steel pipe 4 horizontally along the set position outside the tunnel excavation outline; the pipe shed steel pipe 4. It is jacked by machinery, and the 4 sections of the steel pipe are connected with screws;

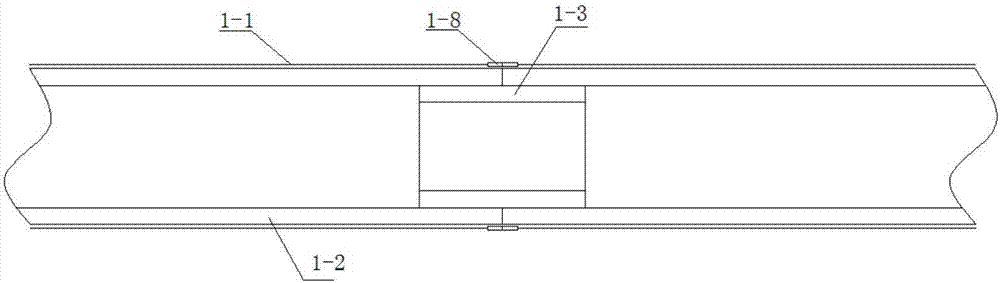

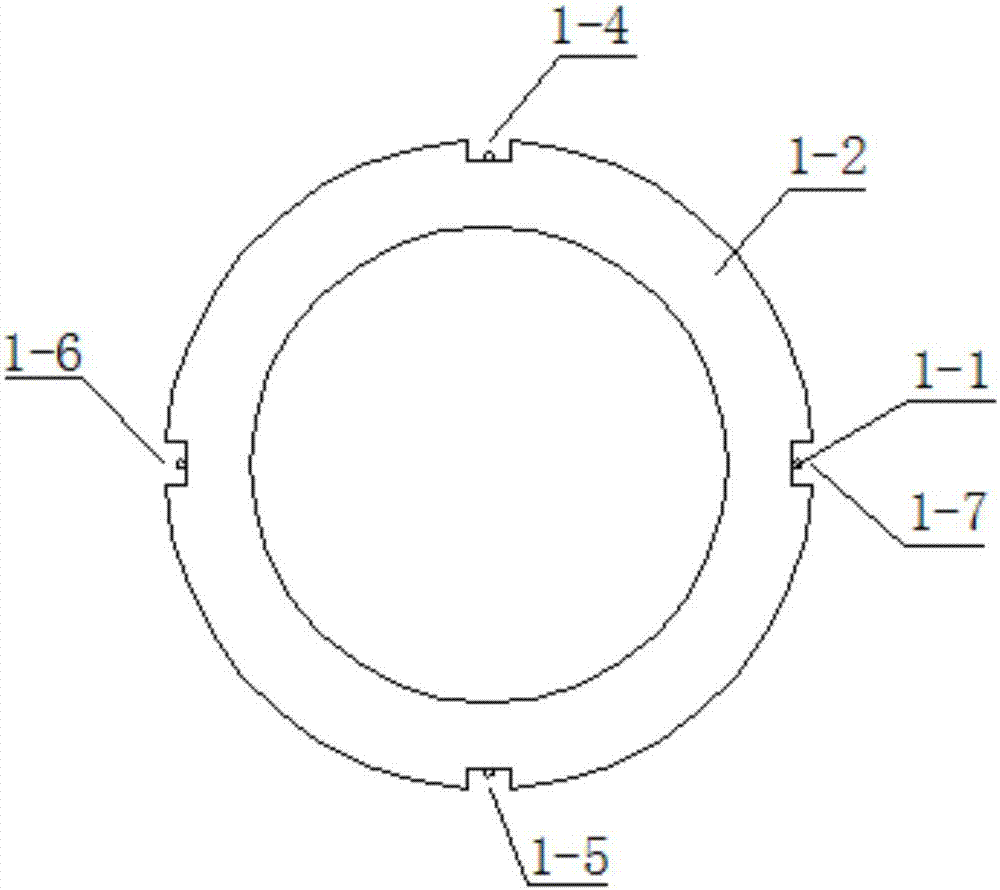

[0055] Step 2. After the top of the steel pipe 4 in the pipe shed is in place, the first groove 1-4 and the second groove 1-5 at the beginning of the first segment of the fiber optic tube single segment 1 are overlapped in series with the fiber conversion extension connector 1-8 , the third groove 1-6 and the fourth groove 1-7 optical ...

Embodiment 2

[0063] according to figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 It can be seen that a distributed optical fiber monitoring device for tunnel surrounding rock deformation based on pipe shed support consists of a single segment of optical fiber measuring pipe 1, optical fiber 1-1, hollow circular pipe 1-2, inner connecting pipe 1-3, the second First groove 1-4, second groove 1-5, third groove 1-6, fourth groove 1-7, extension adapter 1-8, guide pipe 2, monitoring hole 3, pipe shed steel pipe 4 , grout hole 5, guide wall 6, steel arch frame 7, grouting hole 8, optical fiber lead-out pipe 9, and drilling rig 10. The connection relationship is: single segment 1 of optical fiber measuring tube is composed of optical fiber 1-1, extension conversion joint 1-8 and a hollow circular tube 1-2, the outer wall of the single segment 1 of the optical fiber measuring tube is provided with an orthogonally symmetrical first groove 1-4, a second groove 1-5, and a thi...

Embodiment 3

[0070] A method for preparing a single segment of an optical fiber measuring tube, the steps of which are:

[0071] A. According to the length 16m of the supporting steel pipe 4 of the tunnel pipe shed, the single length of the hollow circular pipe 1-2 is determined to be 4m and the quantity is 4 pieces, and the hollow circular pipe 1-2 is grooved, that is, the outer wall of the hollow circular pipe 1-2 The cross-sectional dimensions of the first groove, the second groove, the third groove and the fourth groove opened on the top are all 3mm×3mm, the hollow tube 1-2 the first groove 1-4, the second groove 1-5, the angles between the third groove 1-6 and the fourth groove 1-7 are 180 degrees, 90 degrees (counterclockwise direction) and 90 degrees (clockwise direction);

[0072] B. After the groove is completed, clean the hollow circular tube 1-2 with absolute ethanol to clean the first groove 1-4, the second groove 1-5, the third groove 1-6 and the fourth groove 1-7 The paste s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com