crushing device

A technology of crushing device and containing device, which is applied in the direction of grain processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

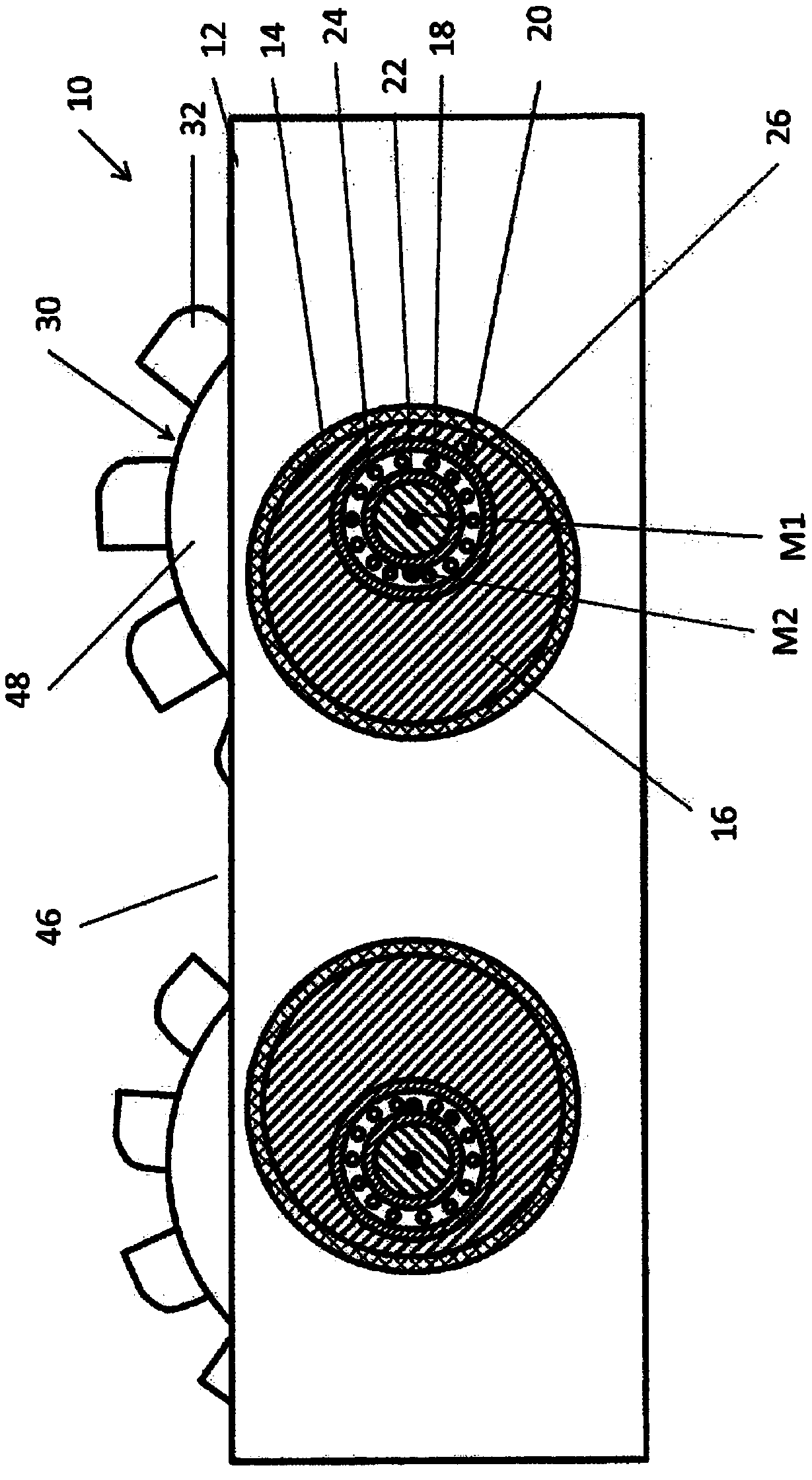

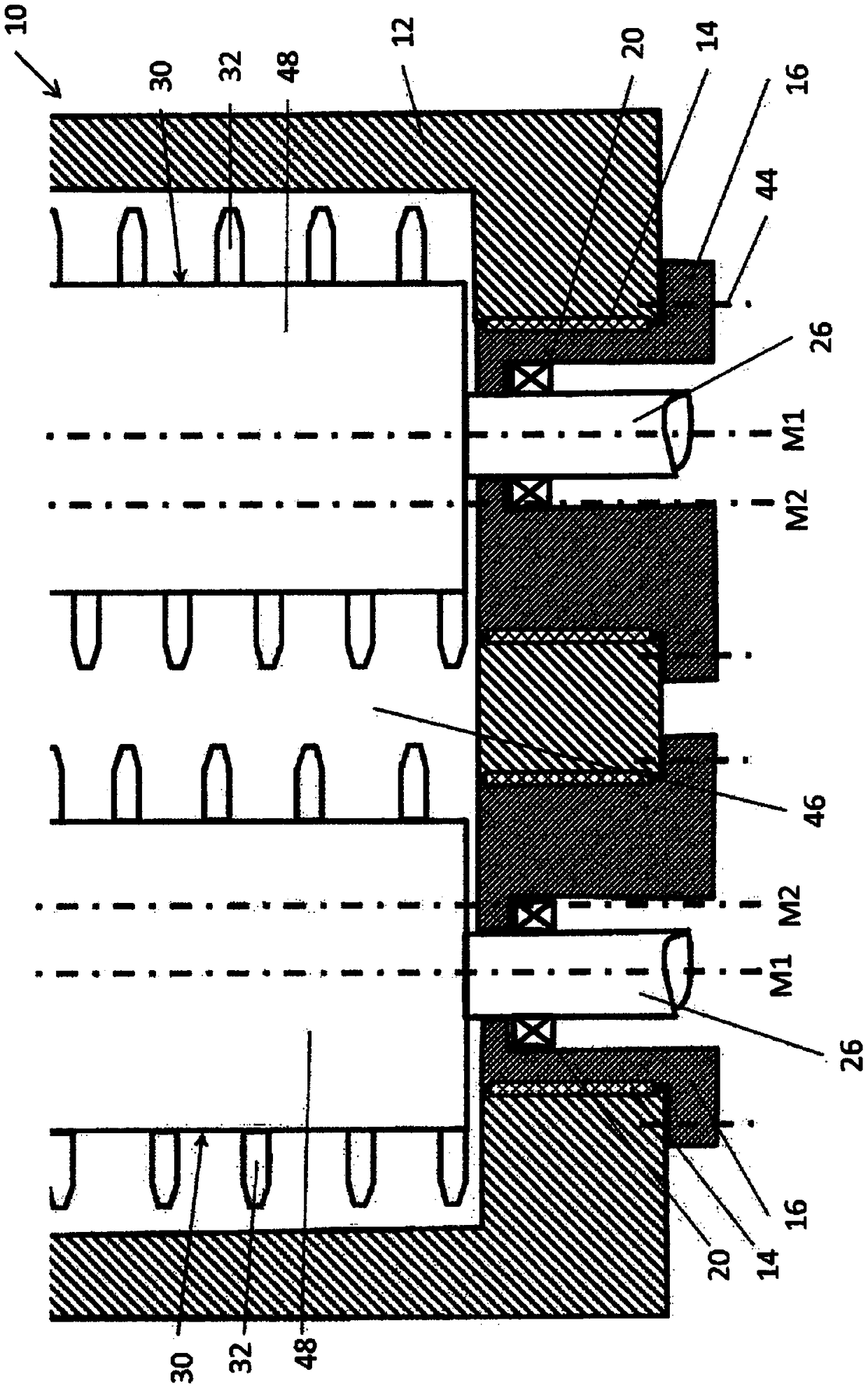

[0032] figure 1 A schematic sectional view of a crushing device, in particular a roller crusher 10 with two crushing rollers 30 is shown. The crushing rollers 30 are arranged parallel to one another and form a crushing gap 46 between one another. The crushing rollers 30 each comprise a shaft portion 26 which extends axially via a roller body 48 fixedly connected to the shaft portion. The roller body 48 has a circular cross section, wherein a plurality of circumferentially spaced apart crushing teeth 32 are arranged on the surface of the roller body 48 .

[0033] The roll crusher 10 has the figure 1 The housing 12 , shown in a rectangular shape, has two circular recesses arranged at the same height, in which a sleeve-shaped receptacle 16 is arranged in each case. The housing is shown in one piece by way of example. It is also conceivable that the housing consists of several housing sections, in particular two housing sections, which will be figure 1 The housing shown in is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com