Method and apparatus for nodule control in titanium-tungsten targets

A target and contract technology, which is applied in metal material coating process, vacuum evaporation plating, coating, etc., can solve the problems affecting the quality of titanium-tungsten film, pollution, and formation on the sputtering surface of the target, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

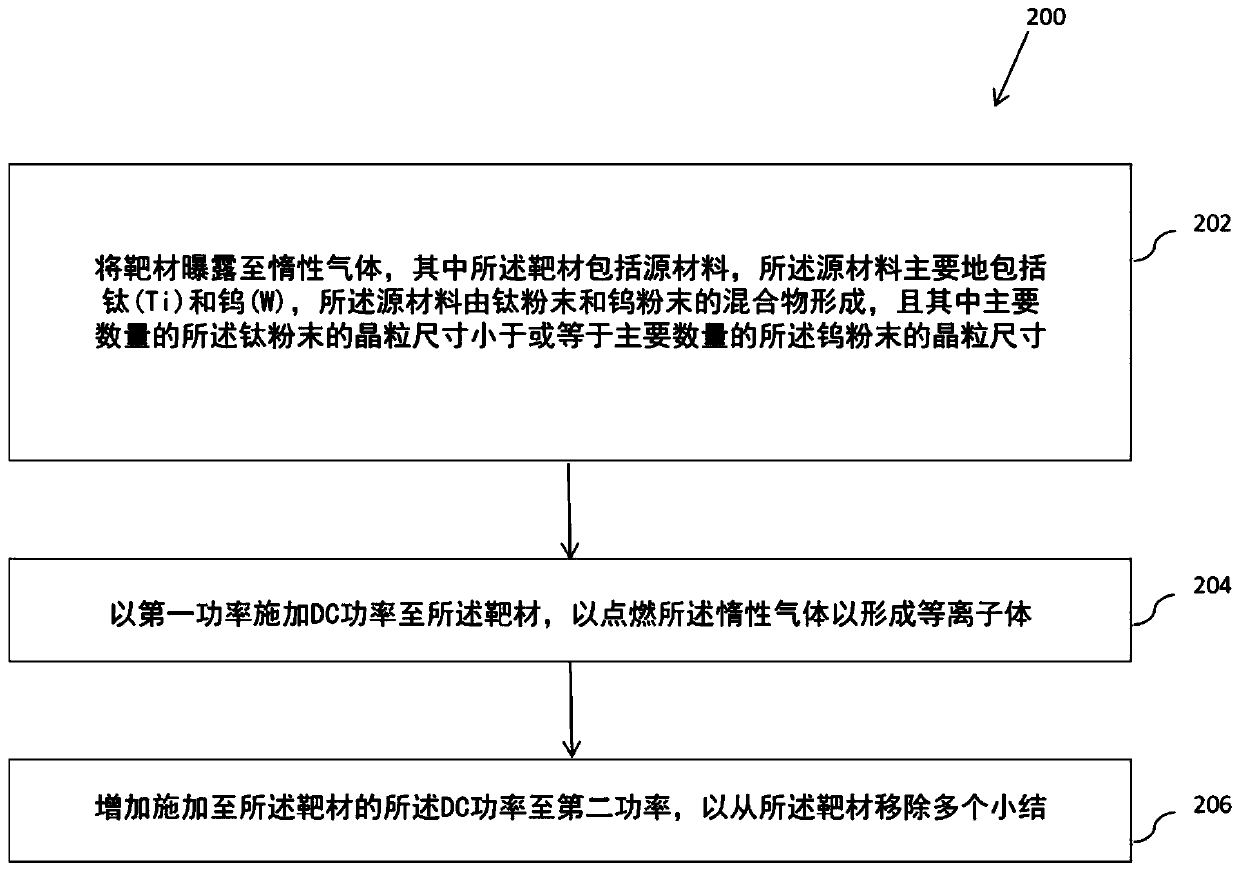

[0013] Embodiments of the present disclosure include methods and apparatus for controlling nodule formation in a titanium-tungsten (TiW) target. In embodiments of the present disclosure, the formation of nodules on titanium-tungsten (Tiw) targets can be advantageously reduced, eliminated, or eliminated by control of the target raw material grain size and by an optional periodic cleaning process. virtually eliminated. In embodiments of the present disclosure, the target grain size control advantageously prevents or delays nodule formation, while the cleaning process advantageously removes any nodules generated on the surface of the target.

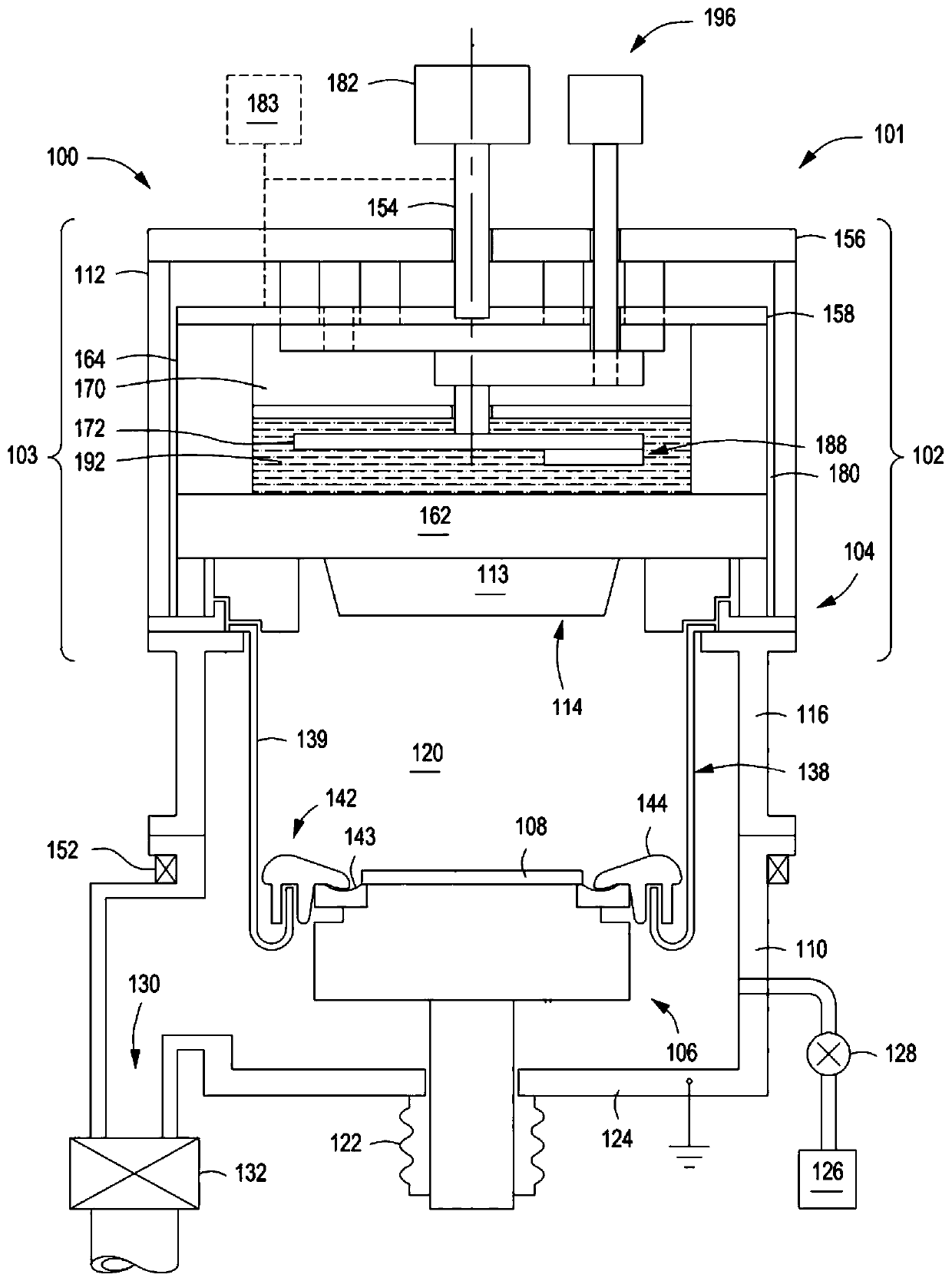

[0014] figure 1 A simplified, cross-sectional view of a physical vapor deposition (PVD) chamber 100 is depicted. PVD chamber 100 includes a substrate support 106 according to some embodiments of the present disclosure. Examples of PVD chambers suitable for modification in accordance with the teachings provided herein include chambers wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com