Device, method and system for ultrasonic signal transducer

A sensor device, ultrasonic signal technology, applied to measuring devices, using sound waves/ultrasonic waves/infrasonic waves for material analysis, instruments, etc., can solve problems such as unsuitable for finding faults or indications, poor resolution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

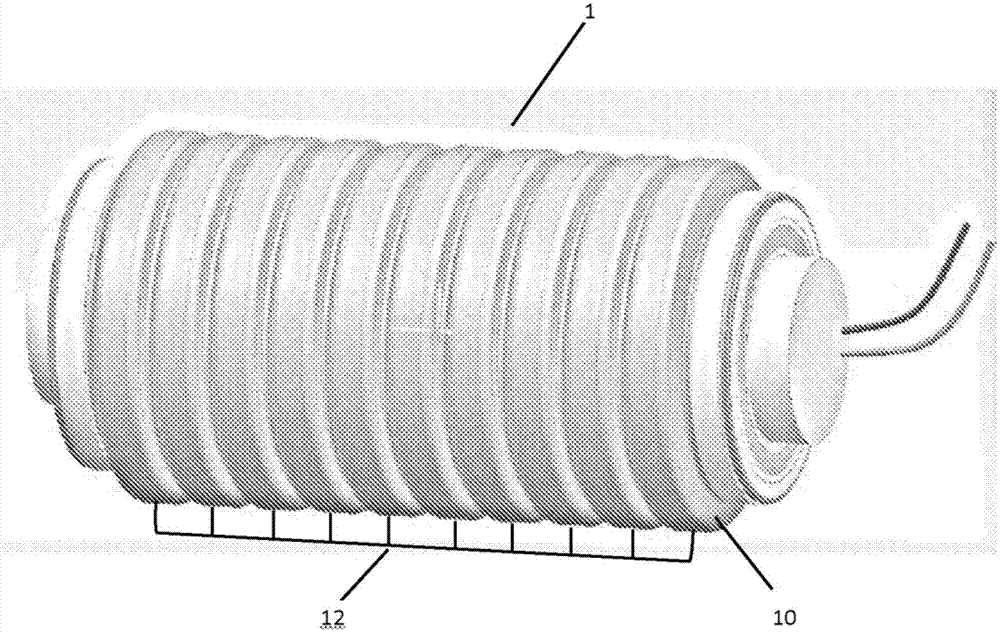

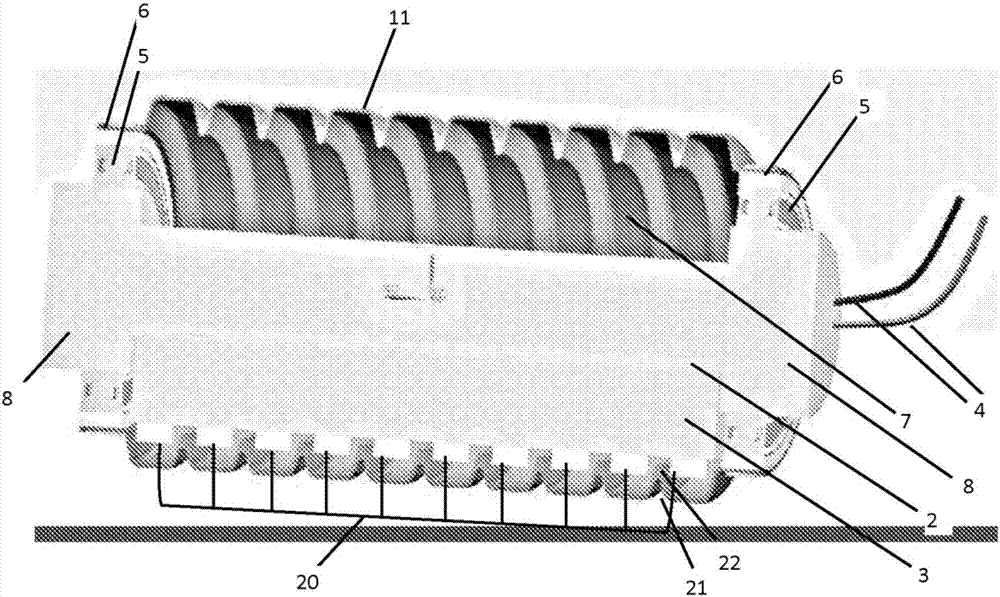

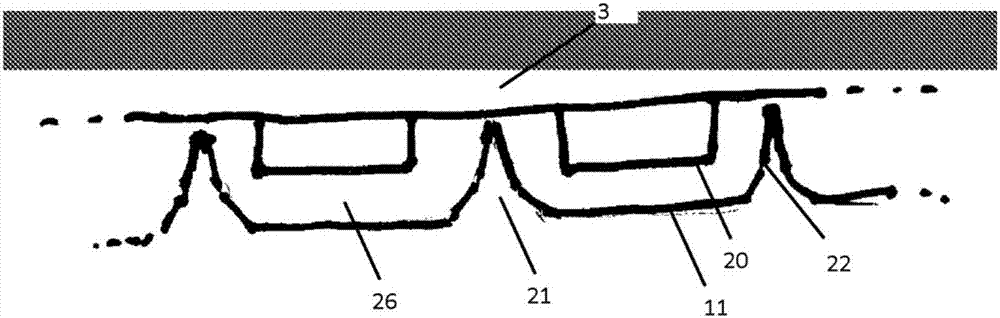

[0057] The present invention is an apparatus for transmitting ultrasonic signals and receiving reflected signals for analysis of test materials, the apparatus comprising an array of ultrasonic sensors located inside a wheel structure with flexible adaptive segmented tires around the sensor array to provide also as a surrounding sensor The sealing fluid of the array fills the rolling motion features of the housing to provide a coupling fluid between the sensor and the tire material in rolling contact with the test material.

[0058] The invention also provides a device for transmitting ultrasonic signals and receiving reflected signals for non-invasive analysis of test materials. This apparatus includes one or more sensor arrays located inside a single wheel structure with flexible adaptive segmented tires around the sensor arrays to provide rolling motion characteristics that also act as a sealed fluid-filled enclosure around the sensor arrays so that the sensors are in contact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com