Universal crusher suitable for seed processing and operation method of universal crusher

A general-purpose shell breaking machine technology, which is applied in the fields of seed and rhizome treatment, application, agriculture, etc., can solve the problems of wide application range, poor versatility, and low quality of seed shell breaking, so as to improve the quality of shell breaking and improve the versatility , Improve the effect of shell breaking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

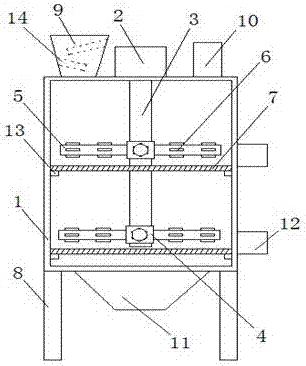

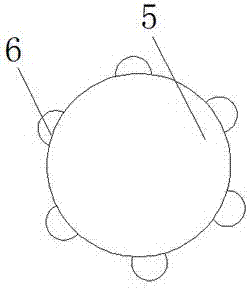

[0021] as attached figure 1 with 2 As shown, a general-purpose cracking machine suitable for seed processing includes a cracking chamber 1, a motor 2, a transmission shaft 3, a connecting block 4, a stirring rod 5, a cracking knife 6 and a vibrating screen 7, and is characterized in that: The shell-breaking chamber 1 is arranged on the bracket 8, and the shell-breaking chamber 1 is provided with a feed inlet 9, a dust outlet 10, a miscellaneous outlet 11, and a material outlet 12, and is provided on the inner wall of the shell-breaking chamber 1. There is a vibrating motor 13, a dividing plate 14 is arranged in the described feeding port 9, the described motor 2 is arranged on the outer wall of the cracking chamber 1, the described transmission shaft 3 is arranged in the cracking chamber 1, and the One end passes through the cracking chamber 1 and is connected to the motor 2, the connecting block 4 is set on the transmission shaft 3, the stirring rod 5 is set on the connectin...

Embodiment 2

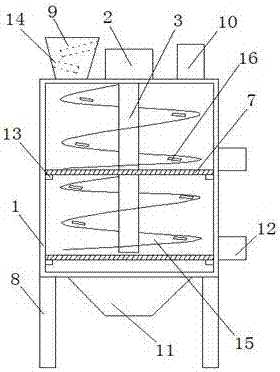

[0028] as attached image 3 As shown, a general-purpose cracking machine suitable for seed processing includes a cracking chamber 1, a motor 2, a transmission shaft 3, a vibrating screen 7 and a lifting plate 15, and is characterized in that: the cracking chamber 1 is set On the support 8, a feed port 9, a dust outlet 10, a miscellaneous outlet 11, and a discharge port 12 are provided on the cracking chamber 1, and a vibration motor 13 is provided on the inner wall of the cracking chamber 1. A partition 14 is arranged in the feed port 9, the motor 2 is arranged on the outer wall of the shell breaking chamber 1, the transmission shaft 3 is arranged in the shell breaking chamber 1, and one end thereof passes through the shell breaking chamber 1 and the shell breaking chamber 1. Motor 2 is connected, and described vibrating screen 7 is arranged on the vibrating motor 13, and described material lifting plate 15 is arranged on the transmission shaft 3, and is provided with broken s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com