Ginkgo crust breaker

A technology of shelling machine and ginkgo, applied in the fields of shelling, pod removal, food science, etc., can solve the problems of low production efficiency, slow speed, inconvenient distance fixing, etc., and achieve increased friction, low labor intensity, and broken shells. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

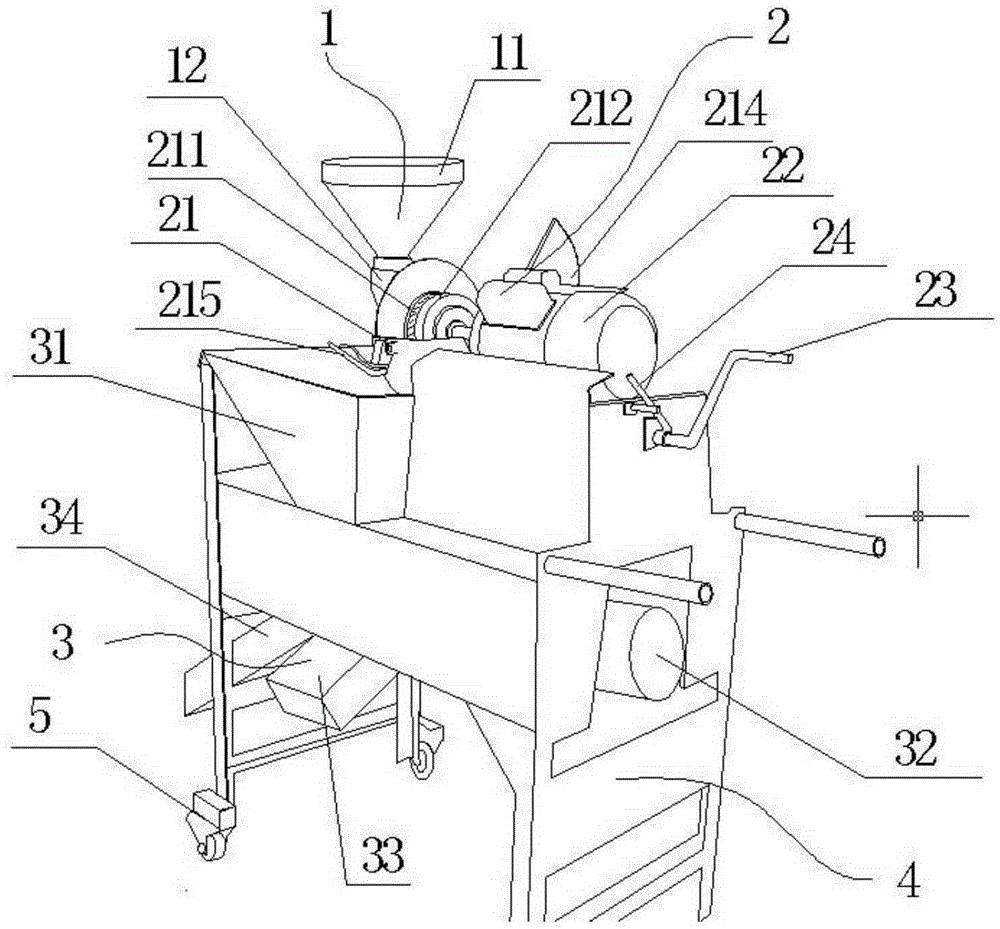

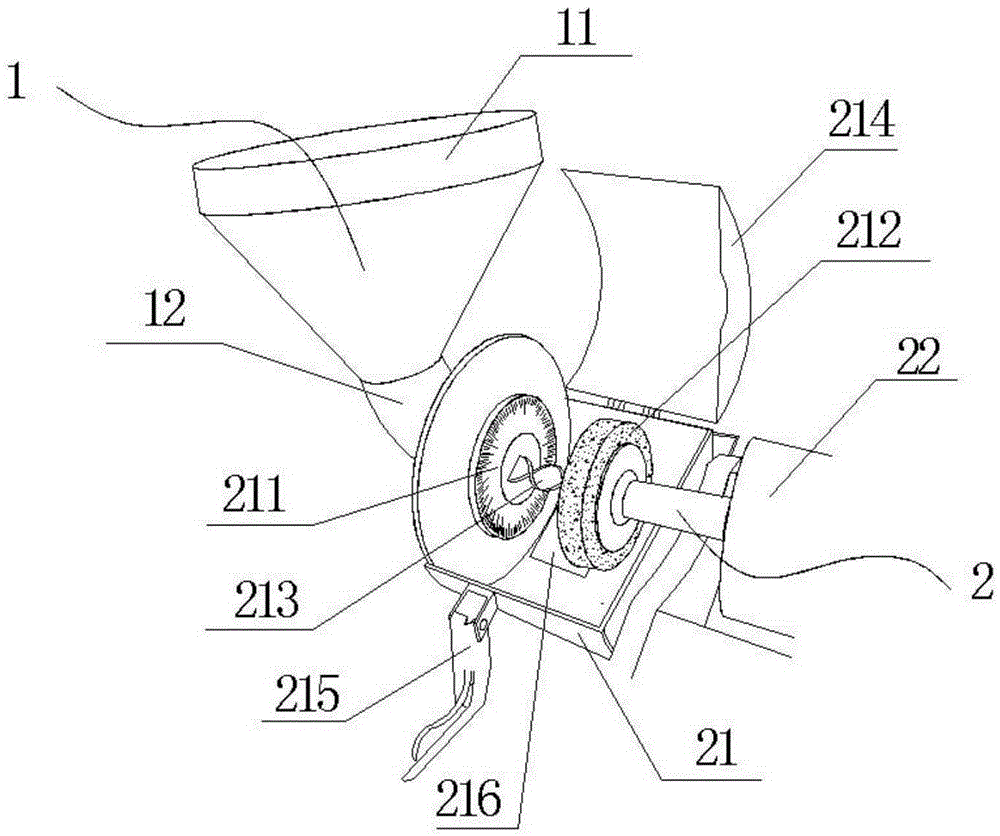

[0022] combined with figure 1 , 2 , the specific embodiment of the present invention is described as follows:

[0023] A ginkgo shelling machine includes a machine body 4, a foot pulley 5, and a ginkgo input device 1, a husk crushing device 2, and a ginkgo separation device 3. The ginkgo input device 1 and the fruit core crushing device 2 are installed on the body 4 , and the ginkgo separation device 3 is installed in the body 4 . The ginkgo input device 1 is used to input the ginkgo core into the shell crushing device 2, the shell crushing device 2 is used to crush the shell of the ginkgo, and the ginkgo separating device 3 is used to separate the broken ginkgo shell and kernel effective separation.

[0024] The ginkgo input device includes a storage bin 11 and a delivery pipe 12. The delivery pipe 12 is arranged below the storage bin 11 and is connected to the discharge port of the storage bin 11. The storage bin 11 is set as a loudspeaker with a large top and a small bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com