Device and method for increasing germination rate of alfalfa under continuous cropping

A technology of germination rate and alfalfa, applied in germination equipment, seed and rhizome treatment, application, etc., can solve problems such as soil deterioration, low seed germination rate, and reduced forage yield, and achieve the goal of increasing contact times and improving shell breaking efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

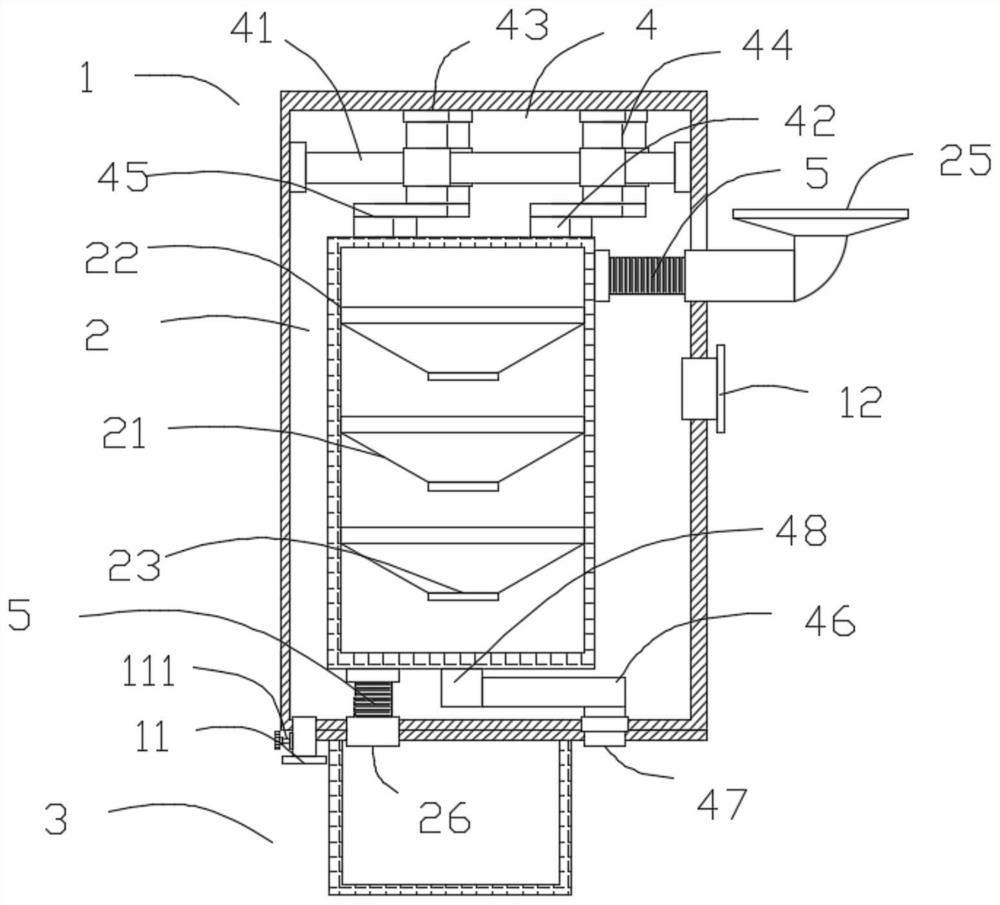

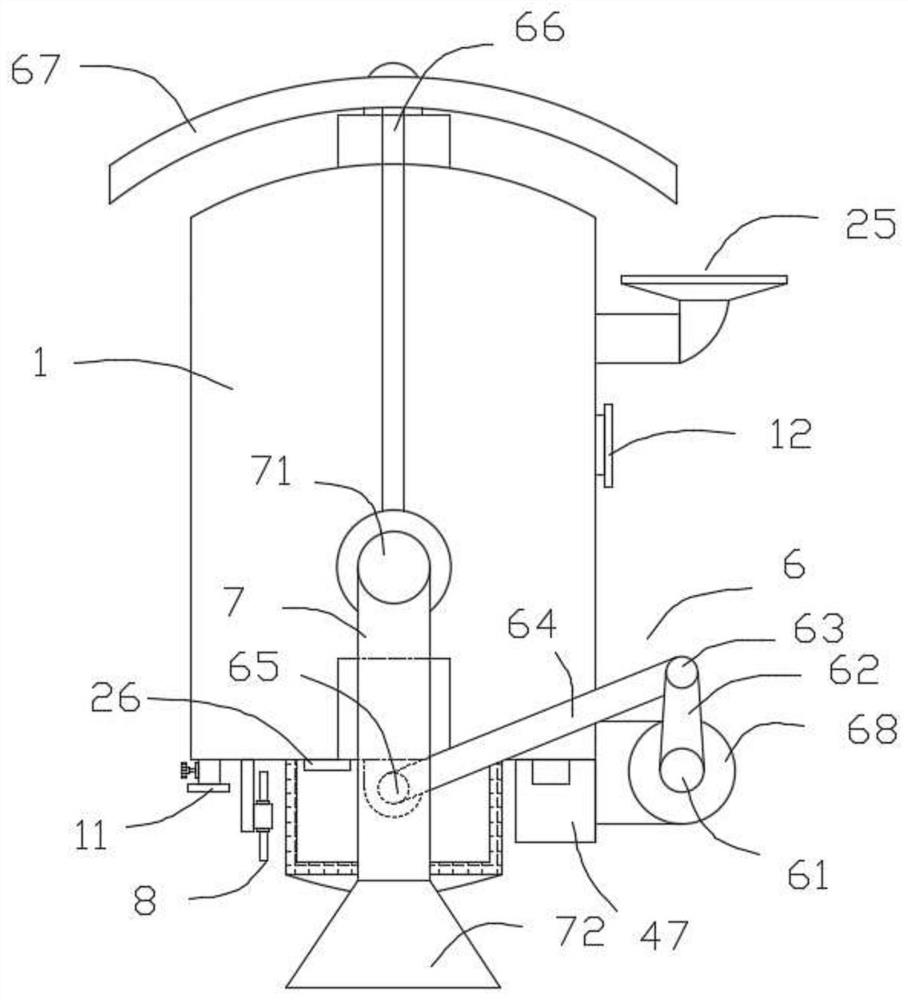

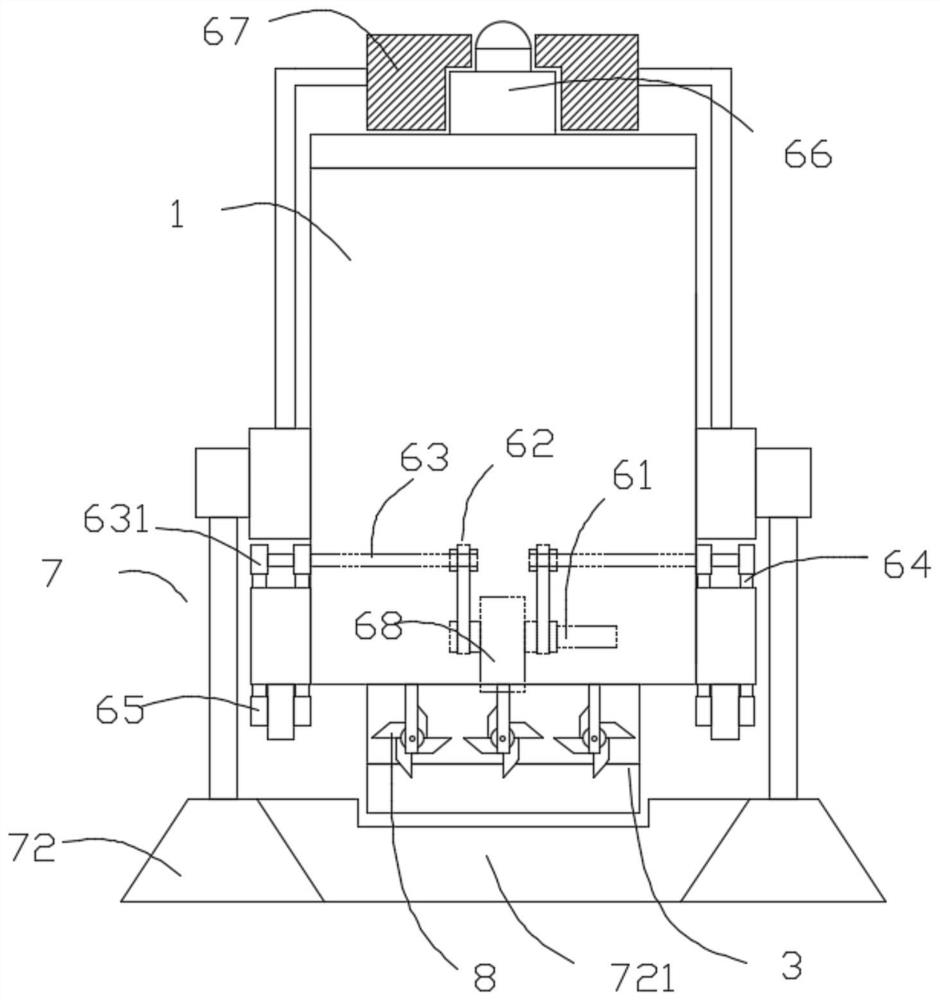

[0033] Such as figure 1As shown, a device for improving the germination rate of alfalfa under continuous cropping mainly includes: a shell 1 for storing water, a shell breaking mechanism 2 arranged inside the shell 1 to accelerate seed breaking, and a shell breaking mechanism 2 arranged in the shell 1. The sieve 3 for collecting and processing the seeds at the bottom, and the power mechanism 4 that can provide power for the shell breaking mechanism 2;

[0034] The shell 1 is provided with a water inlet pipe 12 and a water outlet pipe 11, and the water outlet pipe 11 is also provided with a valve 111;

[0035] Such as figure 1 As shown, the shell breaking mechanism 2 is a cylinder whose shell is a screen, including: a plurality of vertical shell breaking cylinders 21, a feed pipe 25 for seeds to enter and a shell for treated seeds. The discharge pipe 26 that is discharged, the feed pipe 25 penetrates to the outside of the shell 1, the discharge pipe 26 is connected to the scr...

Embodiment 2

[0051] Described embodiment 2 differs from described embodiment 1 in that:

[0052] In the S1 step of the method for promoting the germination of alfalfa seeds in the described embodiment 2, the concentration of the hydrogen peroxide solution is 100ppm.

[0053] The germination rate of alfalfa in this embodiment: 91%

Embodiment 3

[0055] Described embodiment 3 differs from described embodiment 2 in that:

[0056] In the S1 step of the method for promoting the germination of alfalfa seeds in the described embodiment 2, the concentration of the hydrogen peroxide solution is 150ppm.

[0057] The germination rate of alfalfa in this embodiment: 88%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com