A kind of preparation method of copper zinc aluminum zirconium catalyst

A copper-zinc-aluminum, catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc. Improve the effect of promotion, performance improvement, and promotion of promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

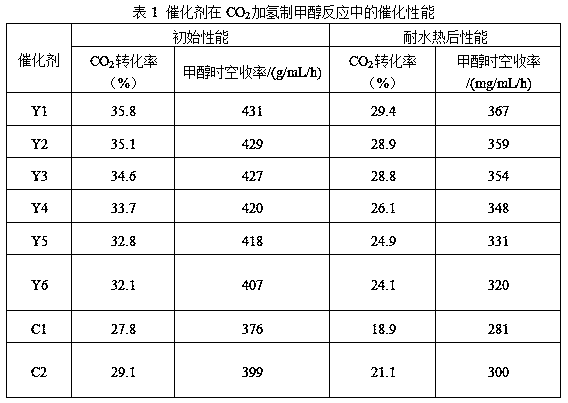

Examples

Embodiment 1

[0016] Weigh 188g Cu(NO 3 ) 2 , 56.7g Zn(NO 3 ) 2 and 21.3g Al(NO 3 ) 2 Dissolve in 2000mL water and preheat to 80°C to form a mixed solution; use 1mol / L Na preheated to 80°C 2 CO 3 The aqueous solution and the above mixed solution were added to 500mL deionized water at 80°C in parallel flow, and the flow rate of the two solutions was controlled to maintain the pH of the deionized water=7. After aging for 1, the primary precipitate was obtained, and the Na was washed with deionized water + , and suction filtered to obtain copper-zinc-aluminum precipitate; weigh 15.95g Zr(NO 3 ) 4 Dissolve in 500mL, 0°C deionized water to obtain a zirconium solution, add ammonia water diluted to 1 / 10 to the above zirconium solution, control the end point pH=6, and obtain α zirconium hydroxide Zr 4 (OH) 8 (OH) 8 Stir the copper-zinc-aluminium-aluminum precipitate and α-zirconium hydroxide in 2000mL deionized water at 0°C for 30 minutes to obtain a copper-zinc-aluminum-zirconium precurs...

Embodiment 2

[0018] Weigh 169.2g Cu(NO 3 ) 2 , 85.05g Zn(NO 3 ) 2 and 191.7g Al(NO 3 ) 2 Dissolve in 2000mL water and preheat to 75°C to form a mixed solution; use 1mol / L NaHCO preheated to 75°C 3 Add the aqueous solution and the above mixed solution into 500mL deionized water at 75°C in parallel flow, control the flow rate of the two solutions to maintain the pH of the deionized water=7.2, obtain the primary precipitate after aging for 1, wash with deionized water to remove Na + , suction filtration to obtain copper-zinc-aluminum precipitate; weigh 54g α zirconium hydroxide Zr 4 (OH) 8 (OH) 8 Stir the copper-zinc-aluminium-aluminum precipitate and α-zirconium hydroxide in 2000mL deionized water at 1°C for 30min to obtain a copper-zinc-aluminum-zirconium precursor; wash the copper-zinc-aluminum-zirconium precursor with 100mL ethanol suction and filter the filter cake in It was dried in a drying oven at 70°C, then calcined at 350°C in a dry air atmosphere for 8 hours, and then flake...

Embodiment 3

[0020] Weigh 150.4g Cu(NO 3 ) 2 , 151.2g Zn(NO 3 ) 2 and 255.6g Al(NO 3 ) 2 Dissolve in 5000mL water and preheat to 80°C to mix the solution; use 0.5mol / L K preheated to 70°C 2 CO 3 Add the aqueous solution and the above mixed solution into 500mL deionized water at 70°C in parallel, control the flow rate of the two solutions to maintain the pH of the deionized water=7.5, and obtain the primary precipitate after aging for 1, wash with deionized water to remove K + , and suction filtered to obtain a copper-zinc-aluminum precipitate; weigh 51.04g Zr(NO 3 ) 4 Dissolve in 1000mL, 2°C deionized water to obtain a zirconium solution, add ammonia water diluted to 1 / 10 to the above zirconium solution, control the end point pH=7.0, and obtain α zirconium hydroxide Zr 4 (OH) 8 (OH) 8 ; Stir the copper-zinc-aluminum precipitate and α-zirconium hydroxide in 5000 mL of deionized water at 2°C for 30 minutes to obtain a copper-zinc-aluminum-zirconium precursor; wash the copper-zinc-a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com