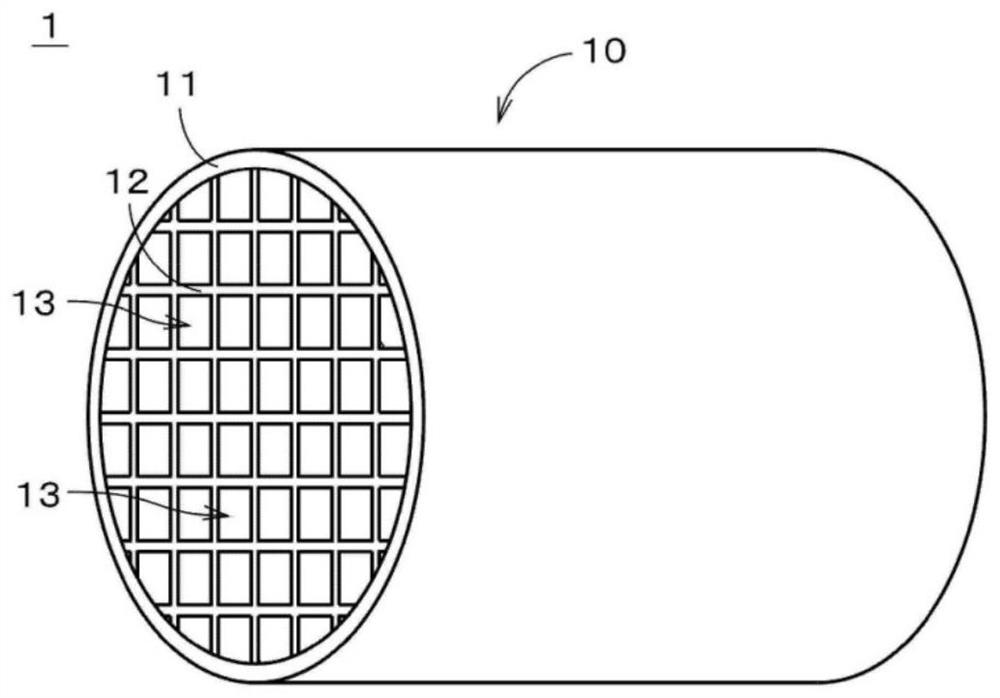

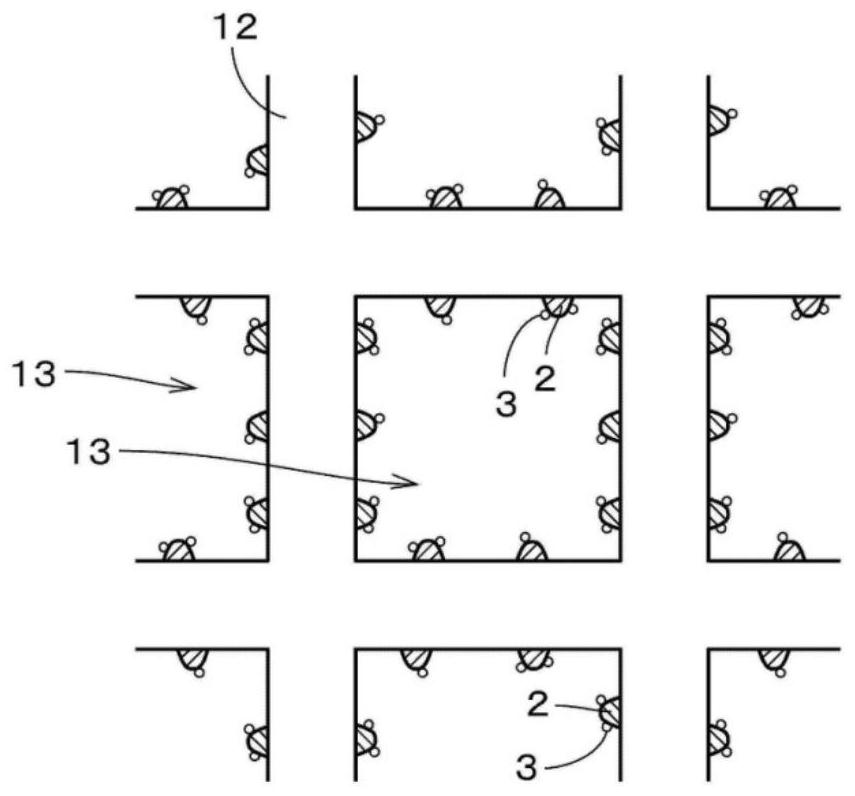

Porous ceramic structure

A ceramic structure, porous technology, applied in ceramic products, gas treatment, catalyst carrier and other directions, can solve problems such as pressure loss increase, and achieve the effect of improving catalytic ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

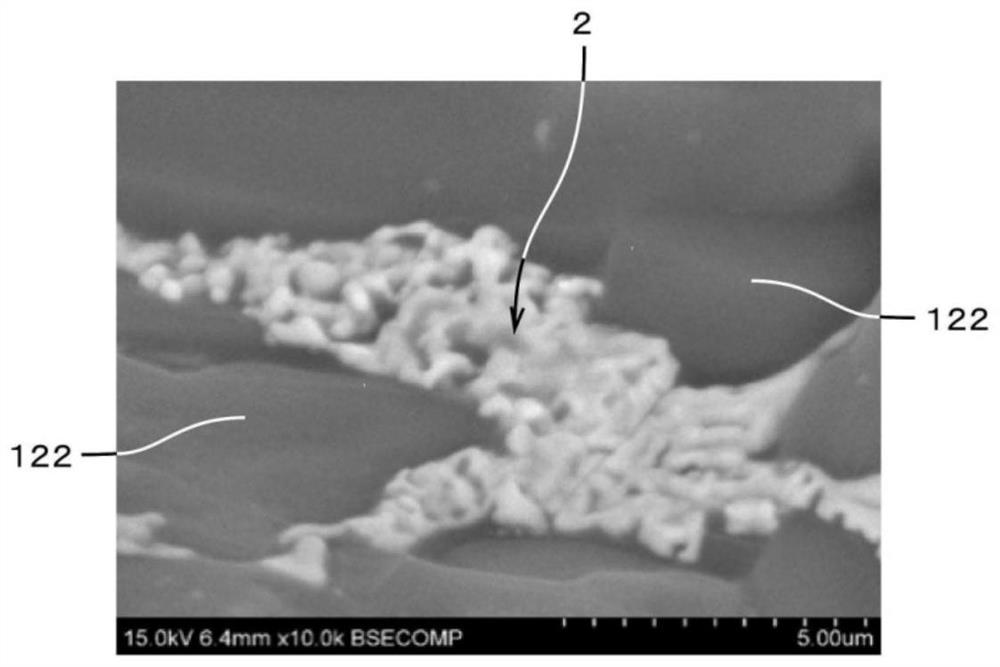

[0063] In embodiment 1, the CeO in material composition 2 and ZrO 2 The content ratios of are 6.1% by mass and 2.0% by mass, respectively. ZrO 2 The content rate of CeO 2 About 1 / 3 of the content rate. The content rate of the Ce-Zr containing particle 2 was 8.1 mass %. The solid solution rate of Zr was 17.2 mol%. The average particle diameter of the Ce—Zr-containing particles 2 was 55 nm. The oxygen storage capacity is as high as 0.0007.

Embodiment 2

[0064] In embodiment 2, the CeO in material composition 2 and ZrO 2 The content rates of and are 7.9% by mass and 2.6% by mass, respectively. ZrO 2 The content rate of CeO 2 About 1 / 3 of the content rate. The content of the Ce—Zr-containing particles 2 was 10.6% by mass. The solid solution rate of Zr was 18.3 mol%. The average particle diameter of the Ce—Zr-containing particles 2 was 120 nm. The oxygen storage capacity is as high as 0.0008.

Embodiment 3

[0065] In embodiment 3, the CeO in material composition 2 and ZrO 2 The content rates of and are respectively 9.6% by mass and 3.2% by mass. ZrO 2 The content rate of CeO 2 About 1 / 3 of the content rate. The content of the Ce—Zr-containing particles 2 was 12.9% by mass. The solid solution rate of Zr was 17.8 mol%. The average particle diameter of the Ce—Zr-containing particles 2 was 630 nm. The oxygen storage capacity is as high as 0.0007.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com