Grille composite for air openings

A composite, vent technology, used in vehicle safety arrangements, superstructures, radiators, etc., to solve problems such as uneconomical handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

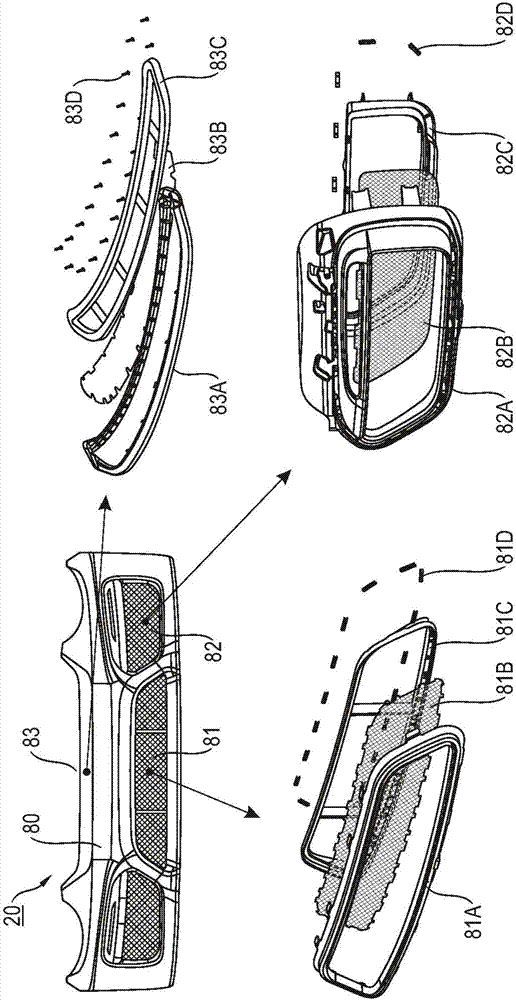

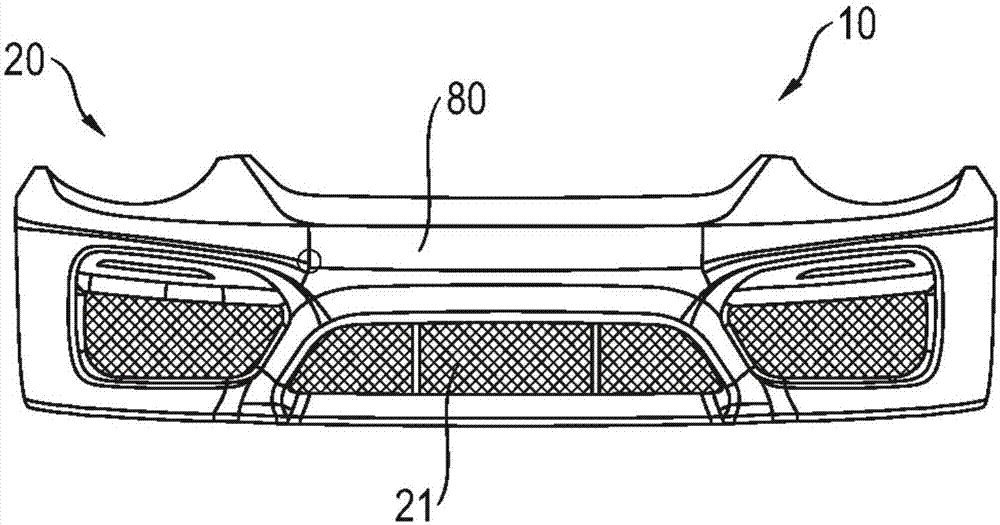

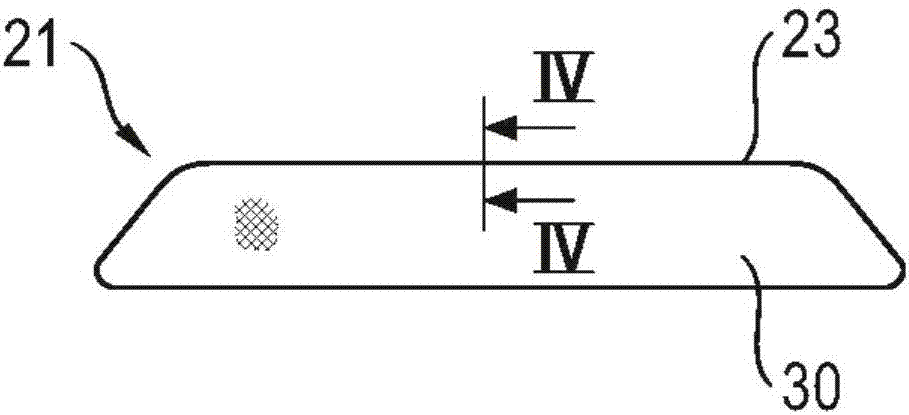

[0039] figure 1 A front region (front region) 20 of a motor vehicle, in particular a passenger car, according to the prior art is shown.

[0040] A front hood 80 is provided in which, for example, a central air intake grille 81 , two lateral air intake grilles 82 and an upper air intake grille 83 are provided as air intakes.

[0041] The central air intake grille 81 has, for example, a front holding frame 81A, a metal grille 81B, a rear holding frame 81C and U-clips 81D as fastening means 18 .

[0042] The lateral air intake grille 82 has a front holding frame 82A, a metal grid 82B, a rear holding frame 82C and U-shaped clips 82D as fastening means 10 .

[0043] The upper air intake grille 83 has an upper holding frame 83A, a metal grid 83B, a lower holding frame 83C and bolts 83D as fastening means 23 .

[0044] The air intake grilles 81 , 82 , 83 are thus realized by a sandwich construction and the metal grilles are correspondingly clamped between two holding frames. Here...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com