Ventilation detection equipment for textiles

A testing equipment and ventilation technology, applied in the direction of measuring devices, instruments, mechanical devices, etc., can solve the problems of difficulty in comprehensively testing the ventilation of textiles, inability to give full play to the ventilation, and inability to freely adjust the wind power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

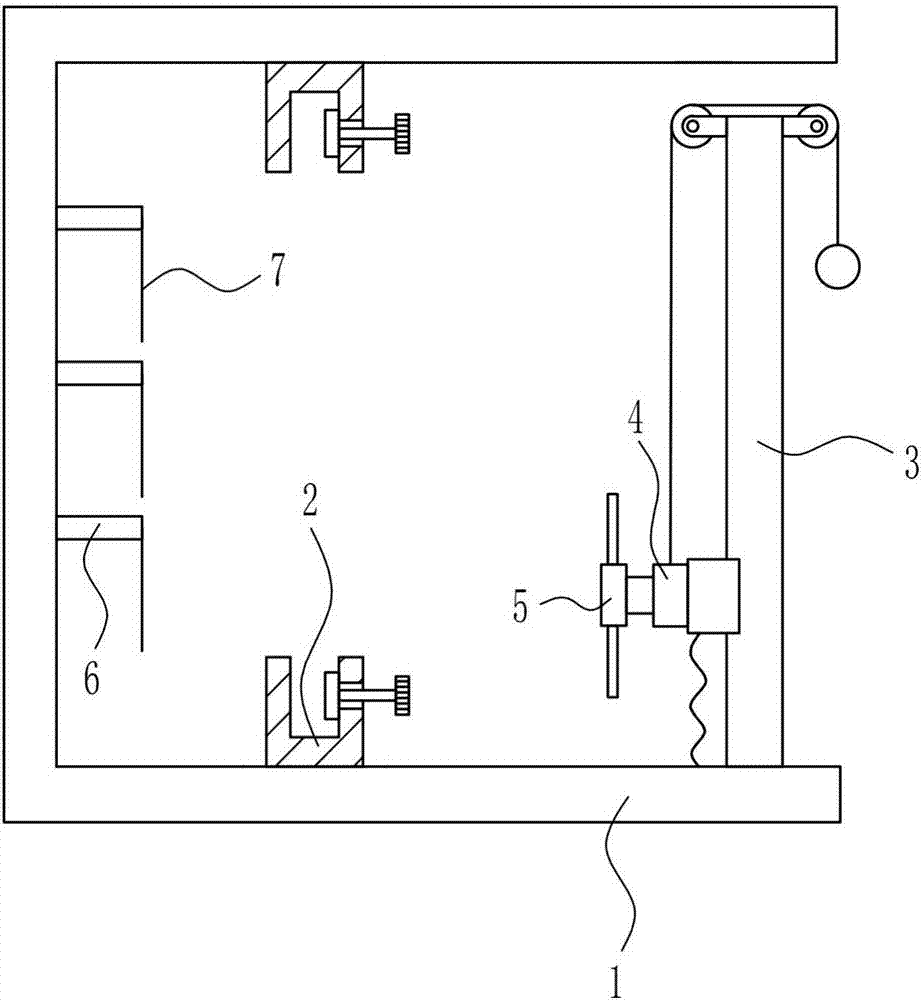

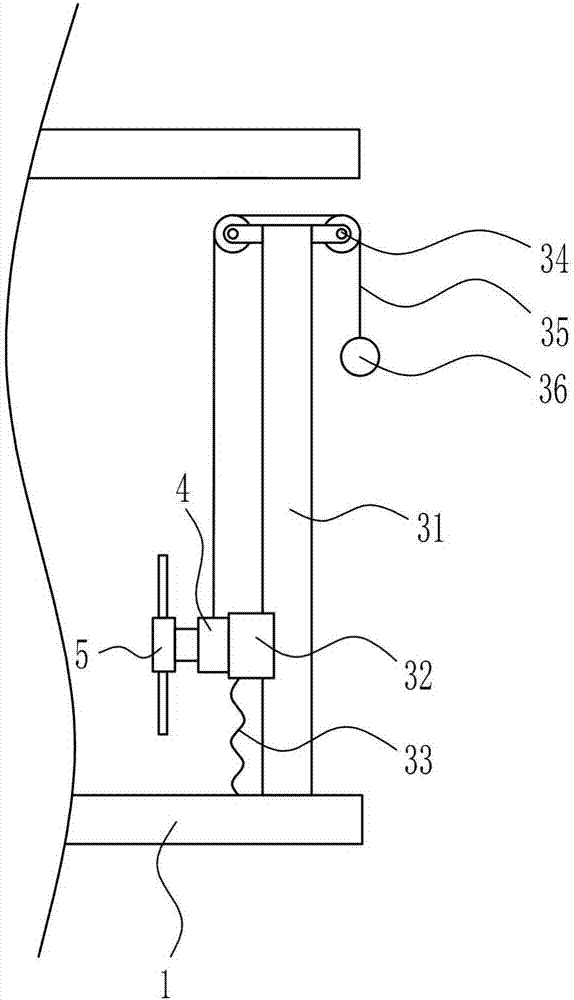

[0031] A textile air permeability detection equipment, such as Figure 1-6 As shown, it includes a mounting frame 1, a fixing device 2, a lifting device 3, a motor 4, a fan 5, a connecting rod 6 and a string 7, and the left side of the inner bottom of the mounting frame 1 and the left side of the inner top of the mounting frame 1 are provided with fixed Device 2, the right side of the inner bottom of the mounting frame 1 is provided with a lifting device 3, the lower left side of the lifting device 3 is provided with a motor 4, the output shaft on the left side of the motor 4 is connected to a fan 5, and the left wall of the mounting frame 1 is evenly provided with connecting rods up and down 6. A string 7 is connected to the right end of the connecting rod 6 .

Embodiment 2

[0033] A textile air permeability detection equipment, such as Figure 1-6 As shown, it includes a mounting frame 1, a fixing device 2, a lifting device 3, a motor 4, a fan 5, a connecting rod 6 and a string 7, and the left side of the inner bottom of the mounting frame 1 and the left side of the inner top of the mounting frame 1 are provided with fixed Device 2, the right side of the inner bottom of the mounting frame 1 is provided with a lifting device 3, the lower left side of the lifting device 3 is provided with a motor 4, the output shaft on the left side of the motor 4 is connected to a fan 5, and the left wall of the mounting frame 1 is evenly provided with connecting rods up and down 6. A string 7 is connected to the right end of the connecting rod 6 .

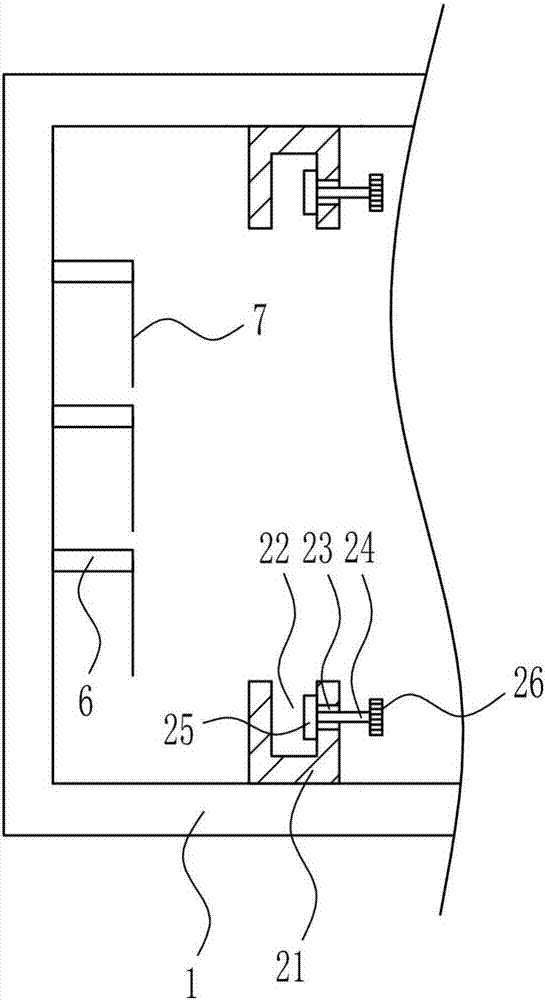

[0034] The fixing device 2 includes a fixing block 21, a bolt 24, a rubber plate 25 and a rubber sleeve 26. The left side of the inner bottom of the mounting frame 1 and the left side of the inner top of the mounting ...

Embodiment 3

[0036] A textile air permeability detection equipment, such as Figure 1-6 As shown, it includes a mounting frame 1, a fixing device 2, a lifting device 3, a motor 4, a fan 5, a connecting rod 6 and a string 7, and the left side of the inner bottom of the mounting frame 1 and the left side of the inner top of the mounting frame 1 are provided with fixed Device 2, the right side of the inner bottom of the mounting frame 1 is provided with a lifting device 3, the lower left side of the lifting device 3 is provided with a motor 4, the output shaft on the left side of the motor 4 is connected to a fan 5, and the left wall of the mounting frame 1 is evenly provided with connecting rods up and down 6. A string 7 is connected to the right end of the connecting rod 6 .

[0037] The fixing device 2 includes a fixing block 21, a bolt 24, a rubber plate 25 and a rubber sleeve 26. The left side of the inner bottom of the mounting frame 1 and the left side of the inner top of the mounting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com