Automatic filter debugging device

An automatic debugging and filter technology, which is applied in the direction of instruments, measuring devices, measuring electronics, etc., can solve problems that affect the pass rate of back-end tests and customer repair rates, high investment in hardware equipment, poor product consistency, etc., to improve debugging efficiency , management standardization, and the effect of ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

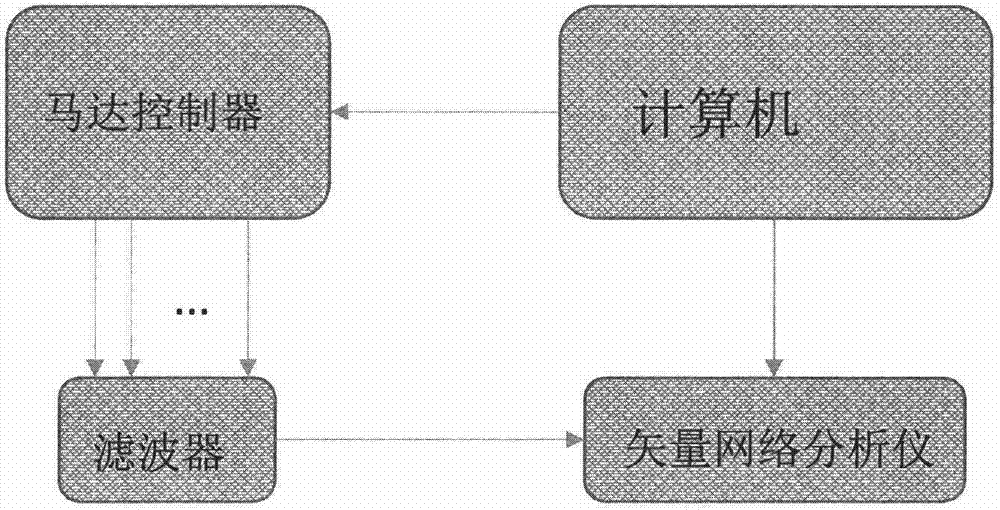

[0011] Such as figure 1 As shown, the filter automatic debugging equipment of the present invention is mainly composed of a vector network analyzer, a computer, a motor controller and a motor, and the target filter to be debugged, the vector network analyzer, the computer, the motor controller and the output end of the motor are connected in sequence. Among them, the vector analysis network analyzer is used to measure the filter to obtain the S parameter of the filter; the computer is used to compare and analyze the measurement data and the standard data, and the motor controller receives the control quality output by the computer to realize the control of the motor , through the change of the motor rotation direction or rotation angle to realize the debugging of the filter index.

[0012] The specific process is as follows:

[0013] (1) star...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com