A continuous zoom optical device

A technology of optical devices and optical systems, applied in the field of optical systems, can solve the problems of increased volume and weight of optical devices, unfavorable miniaturization design, etc., and achieve the effect of reducing the entrance pupil distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

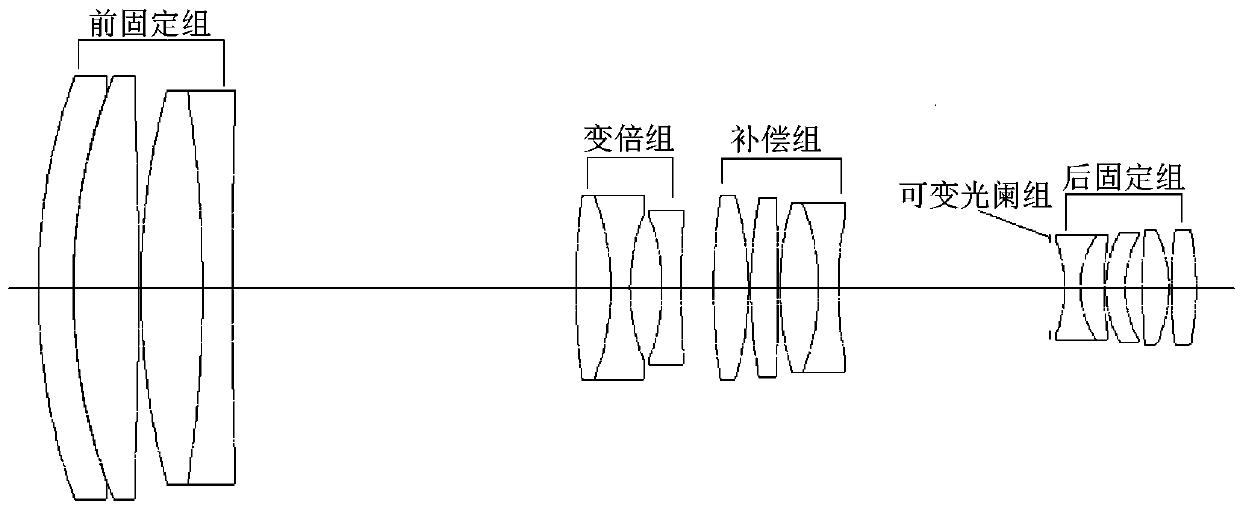

[0023] Such as Figure 5 to Figure 7 As shown, a basic embodiment of a continuous zoom optical device with a small aperture and a large amount of light in the present invention, it includes being installed on the same optical axis O-O, and the total length of the optical system changes accordingly during the process of continuously changing the focal length, and the distance between the image plane 6 Five components that remain unchanged, three moving along the direction of the optical axis, one moving in the direction perpendicular to the optical axis, and one fixed on the optical axis: the five mirror groups take the end of the compensation group 1 where the light enters as the front end , one end of the image plane 6 is the rear end, which are arranged in order from front to back: compensation group 1, zoom group 2, iris group 3, focusing group 4 and rear fixed group 5.

[0024] The compensation group 1 is a positive refractive power group with a dual structure, which is us...

Embodiment 2

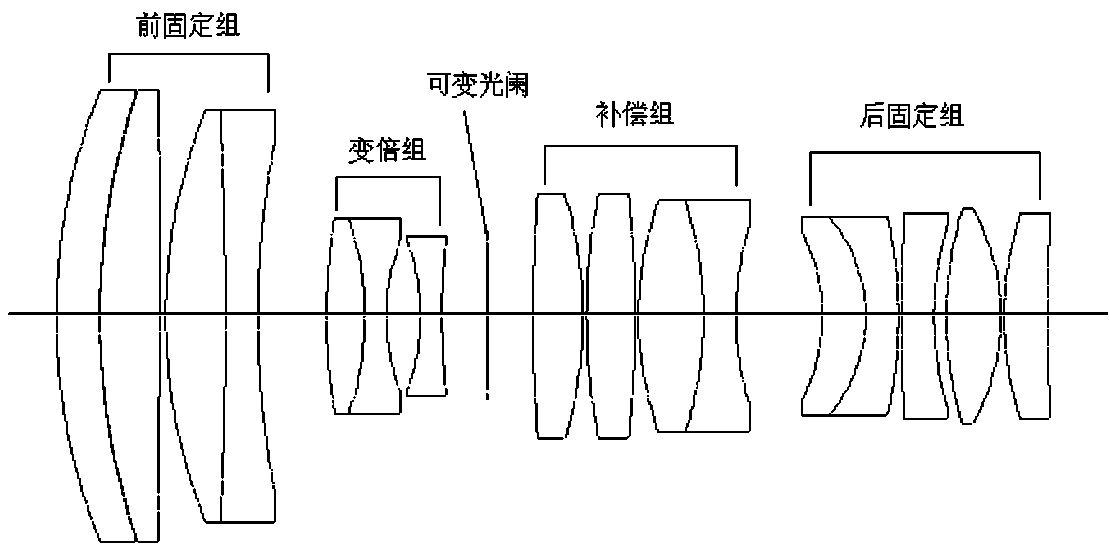

[0030] It is a further technical scheme on the basis of embodiment 1.

[0031] The relative aperture D / f of the compensation group 1 is 1 / 1.9, and from the front to the back is: a double cement composed of a high refractive index medium dispersion lanthanum flint positive meniscus lens and a low dispersion low refractive index light crown biconvex lens The lens is a doublet lens composed of a low dispersion low refractive index light crown biconvex lens and a high refractive index high dispersion heavy flint biconcave lens.

[0032] The variable magnification group 2 is as follows from front to back: a doublet lens composed of a high refractive index high dispersion heavy flint biconvex lens and a medium refractive index low dispersion lanthanum crown biconcave lens, and a low dispersion heavy barium flint negative meniscus lens .

[0033] The iris group 3 is located at a fixed position between the zoom group 2 and the focus group 4, and the aperture of the light is variable....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com