Thermoplastic material filter screen baffle and extrusion device

A technology of thermoplastic materials and extrusion devices, applied in the field of extrusion devices, can solve problems such as affecting product quality, reducing product yield, and product failure, and achieves the effects of uniform state, quality improvement, and quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to describe the technical content, structural features, and achieved effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

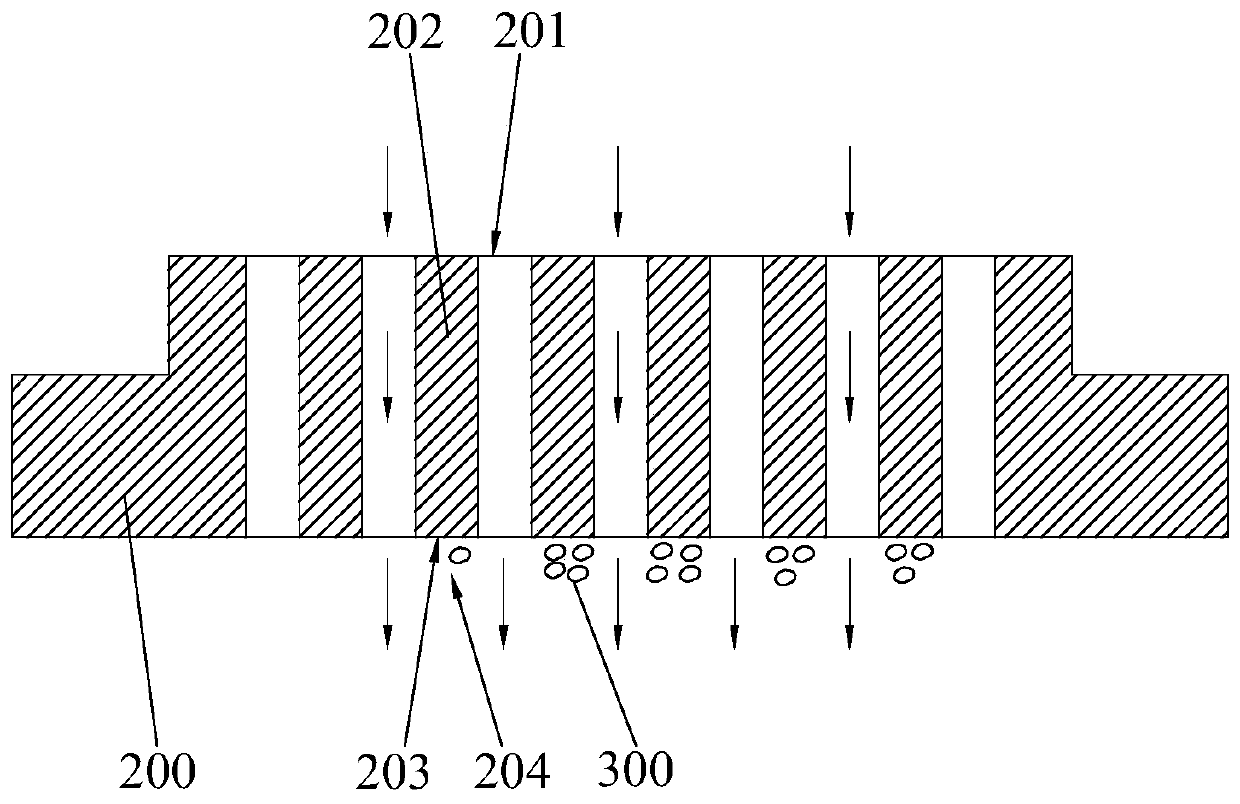

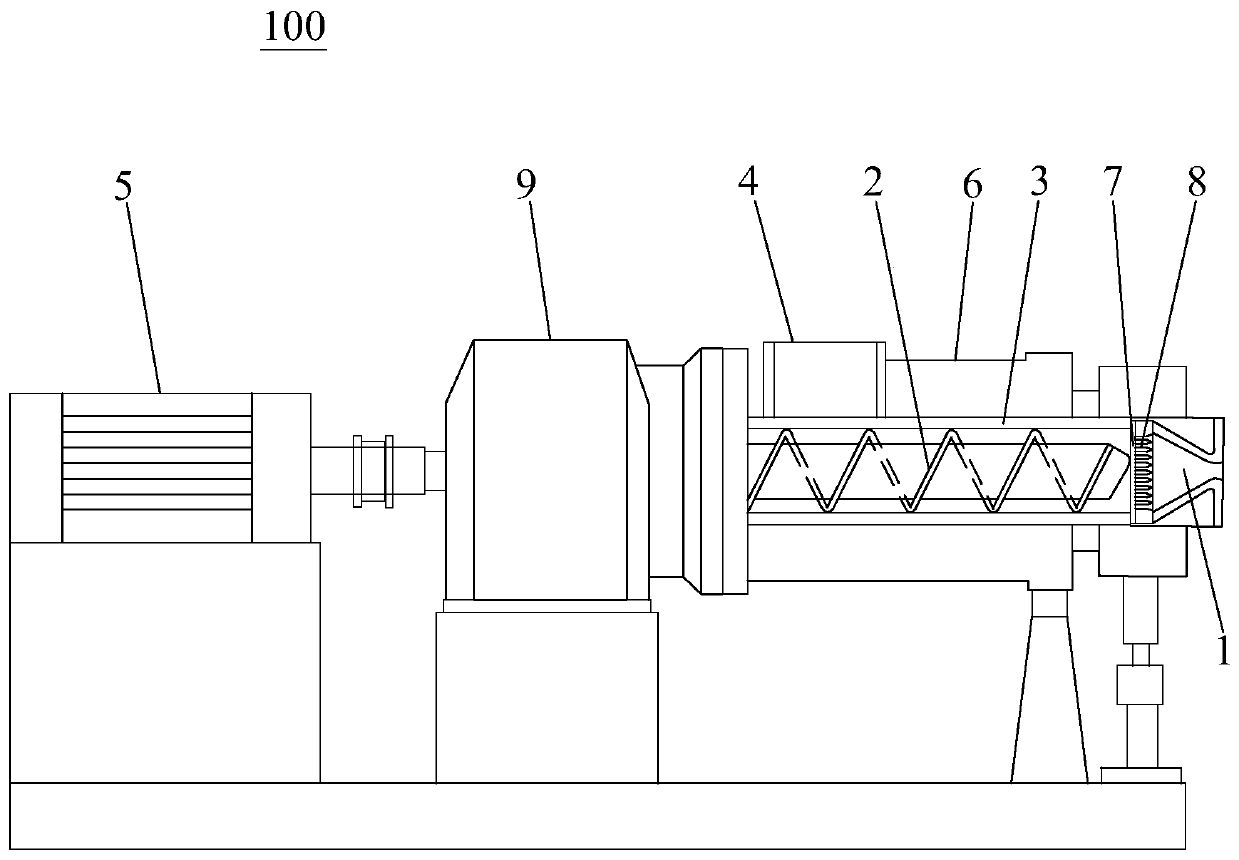

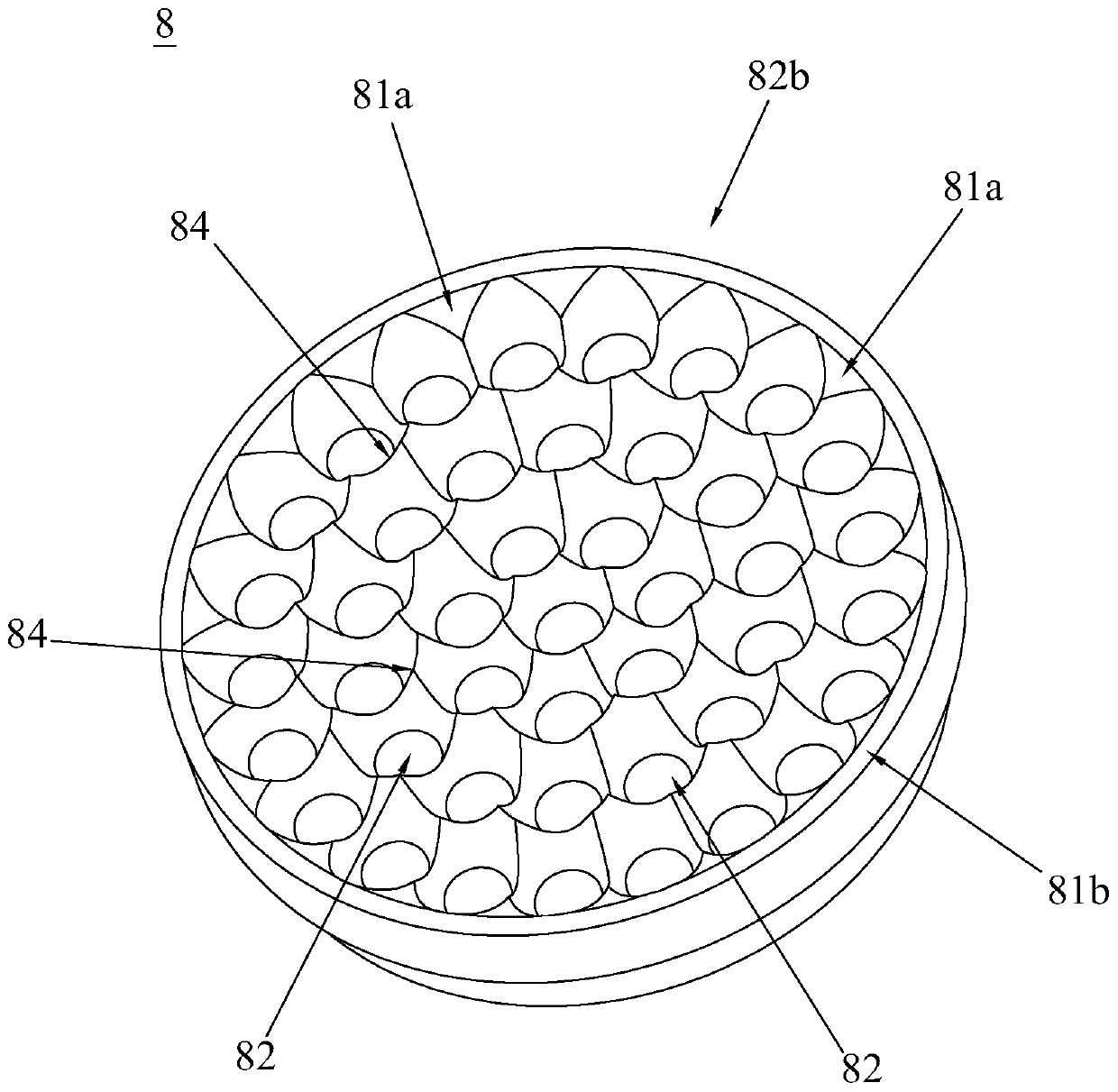

[0024] Such as Figure 2 to Figure 5 As shown, the thermoplastic material extrusion device 100 of the present invention includes an extrusion nozzle 1, a screw 2, a screw barrel 3, a feeding mechanism 4, a motor 5, a heating device 6, a filter 7, a filter baffle 8 and a reduction box , the screw 2 is built in the screw barrel 3, the extrusion nozzle 1 is set at one end of the screw barrel 3, and the filter baffle 8 is set at the screw barrel 3 close to the extrusion nozzle 1, the filter 7 is set on one side of the inlet 82a of the filter baffle 8, the feeding mechanism 4 is set on the other end of the screw barrel 3, and the heating device 6 is set on the outside the screw barrel 3 and heat the material in the screw barrel 3; the output end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com