A kind of heat radiation welding device and welding method

A welding method and a technology of a welding device, which are applied in the field of heat fusion welding of large heat exchanger tube sheets, and can solve problems such as the one-time welding process of heat exchangers that cannot be solved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

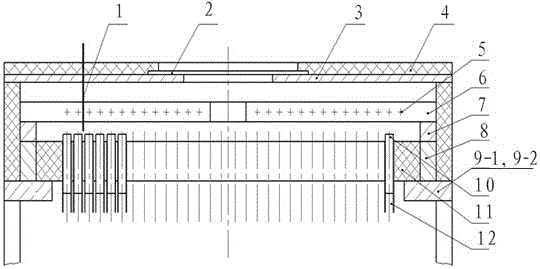

[0024] Such as figure 1As shown, a heat radiation welding device includes a heating element, a welding fixture, a composite cover, and a temperature control system. The welding fixture is connected to the composite cover; when the porous end plate to be welded is installed in the welding fixture, the The welding fixture, the porous end plate and the composite cover plate form an airtight constant temperature chamber; the heating element is installed in the airtight constant temperature chamber, and the temperature control system connects the airtight constant temperature chamber and the heating element. The heating element is composed of a heat pipe 5 and an aluminum mounting plate 6, and the heat pipe is installed on the aluminum mounting plate. The aluminum height adjustment ring 7 is combined with the mold frame strip 8 to form a welding fixture, the molding cavity, the bottom cabinet 9-1 and the bracket 9-2 are combined to form a welding fixture, and the quartz glass obser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com