Automatic variable diameter device of reinforcement cage (skeleton) seam welder

A technology of rolling welding machine and steel cage, which is applied in the direction of roller electrode welding, welding equipment, resistance welding equipment, etc., can solve the problems of complicated equipment fabrication and installation, long time for changing type, and small diameter change range. To achieve the effect of shortening the replacement time, simple and convenient maintenance and maintenance, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

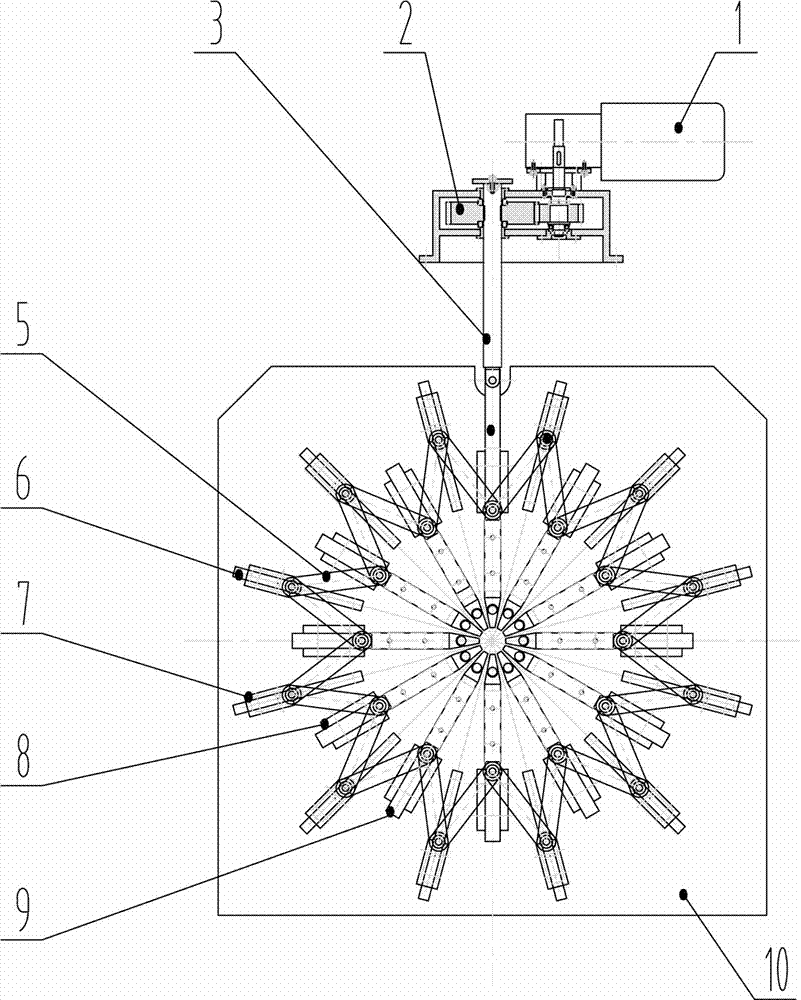

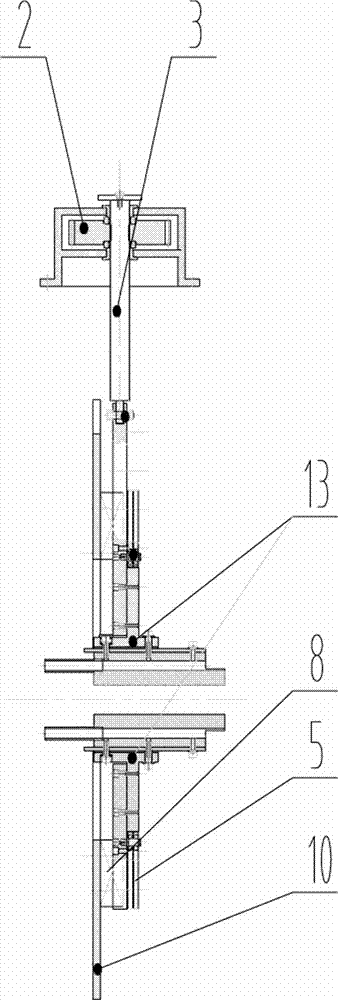

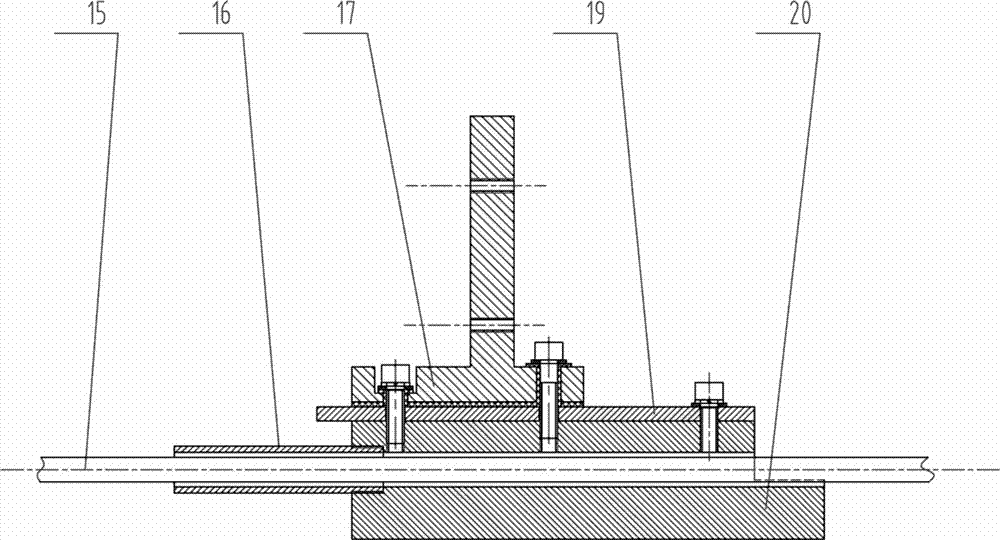

[0027] Such as figure 1 , figure 2 As shown, a diameter reducing device of a steel cage roll welding machine includes a mounting plate 10 and a plurality of first limiting devices 8 evenly arranged with point P on the mounting plate 10 as the center of the circle, and the first limiting devices 8 slide The moving position of guide rod 9 is limited. Preferably, the first position limiting device 8 is a sliding sleeve with two open ends, and the sliding guide rod 9 penetrates from one end of the sliding sleeve and passes out from the other end. The sliding guide rod 9 reciprocates along the straight line from the point P to the center point of the first limiting device 8;

[0028] A second limiting device 7 is arranged between adjacent two first limiting devices 8, and the second limiting device 7 limits the moving position of the transition guide rod 6. Preferably, the second limiting device 7 is a two-terminal Open sliding sleeve, the transition guide rod 6 penetrates from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com