Emergency system for engineering machinery after failure of hydraulic system

A technology for hydraulic systems and construction machinery, which is applied to the safety of fluid pressure actuation systems, mechanical equipment, and fluid pressure actuation devices. High practical value, obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

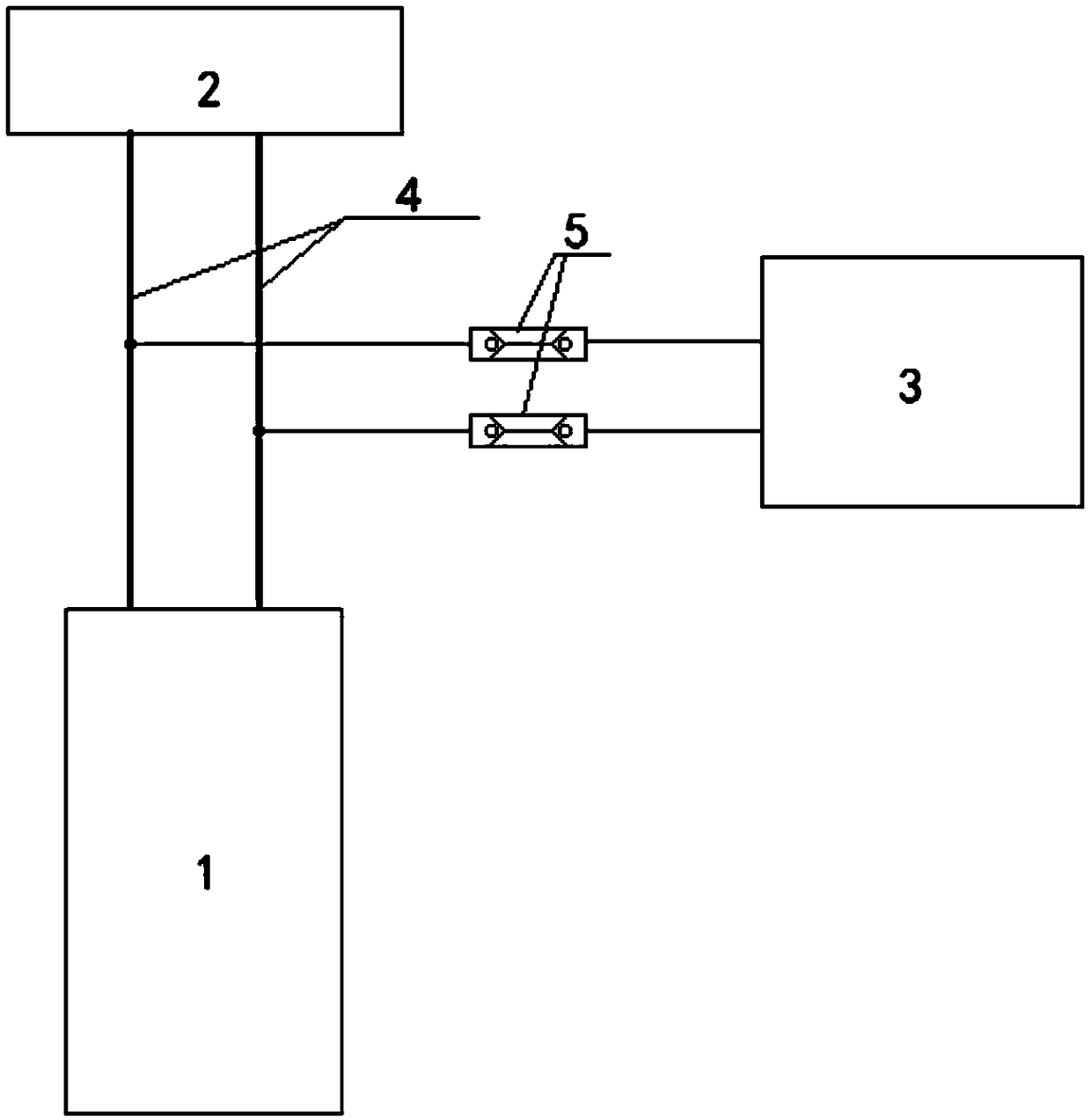

[0025] The emergency system after the failure of the hydraulic system of construction machinery is to add emergency power equipment 3, quick-change joints 5, tee joints, hydraulic hoses, etc. to the original pipeline on the basis of basically not changing the original hydraulic system of construction machinery. Such as figure 1 As shown, the main power equipment 2 provides high-pressure oil for the hydraulic equipment 1 through the hydraulic pipeline 4. The hydraulic pipeline 4 includes an oil inlet pipe and an oil discharge pipe. The end of the root emergency pipe is provided with a quick-change joint 5 . The emergency power equipment 3 is a backup oil supply device, which provides a backup power source for the hydraulic system of construction machinery. Both the oil inlet pipe and the oil discharge pipe are connected to the emergency pipe through a three-way joint. The ends of the two emergency pipes are provided with quick-change joints 5. The oil outlet and the oil inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com