High-precision hydraulic press

A hydraulic press, high-precision technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of guide plate shaking, affecting the forming accuracy of the workpiece, and the deviation of the upper mold's downward route, and achieve the effects of tight and reliable contact, improved elasticity, and reduced wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings.

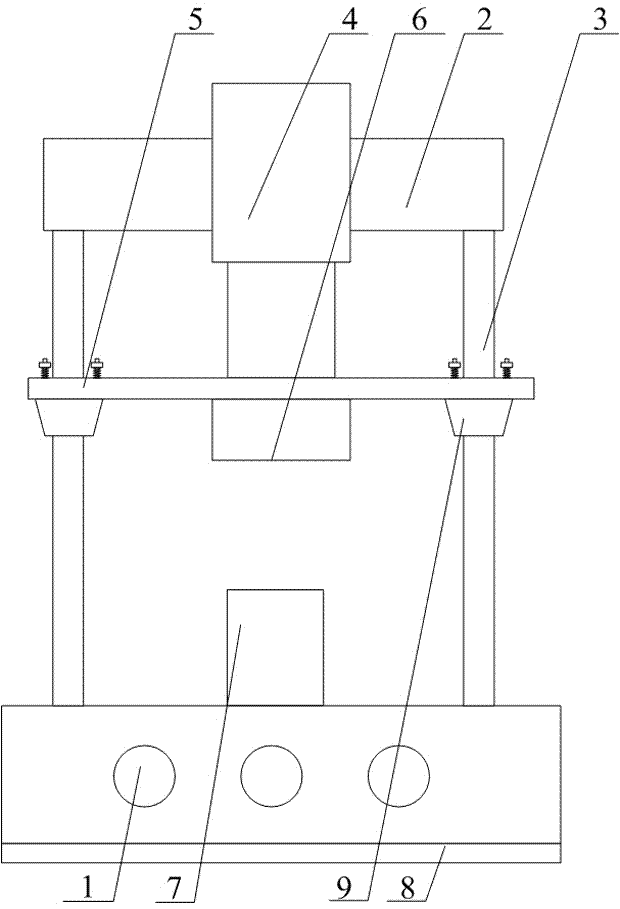

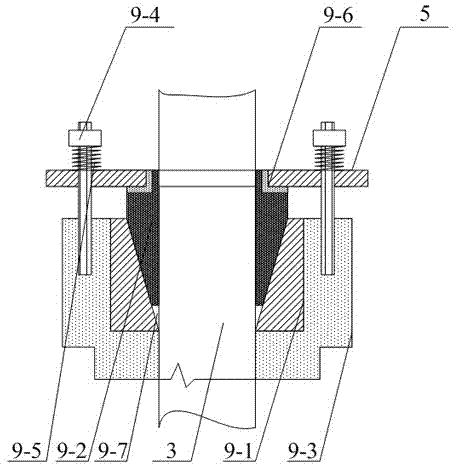

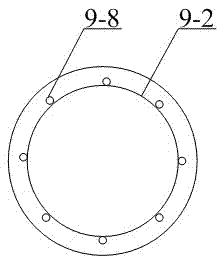

[0013] like figure 1 As shown, the high-precision hydraulic press of the present invention includes a base 1 , an upper die 6 , a lower die 7 , an upper frame 2 , a hydraulic jack 4 and a guide column 3 . The four corresponding corners of the upper frame 2 and the base 1 are respectively connected with guide posts 3 , and rubber pads 8 are laid on the bottom of the base 1 . The hydraulic jack 4 is installed on the upper frame 2 and is connected with the hydraulic system (not shown in the figure). The lower end of the push-pull rod of the hydraulic jack 4 is connected to the guide plate 5, and the four corners of the guide plate 5 have holes corresponding to the four guide columns 3, and the lower part of the guide plate 5 is connected to the upper mold 6, and the hydraulic jack 4 passes through the guide plate 5 The upper mold 6 is driven to run up and down...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com