Liquid supply device, printing apparatus and liquid ejection system

A technology for liquid supply, printing device, applied in the direction of printing, printing device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0132] A-1. Structure of liquid injection system:

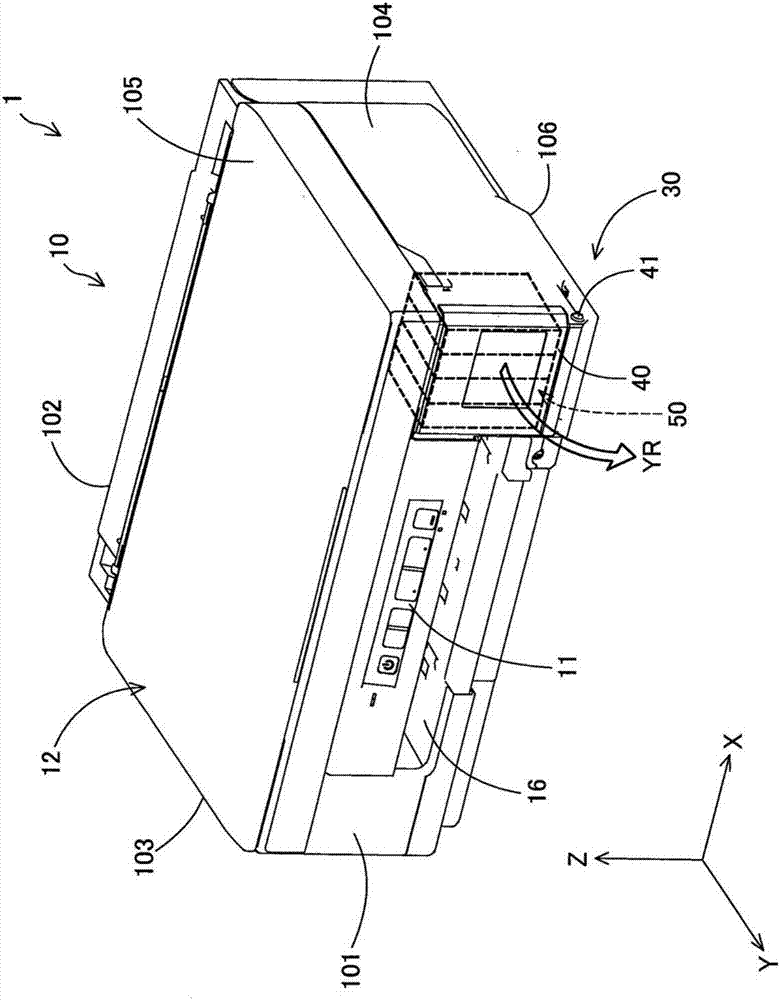

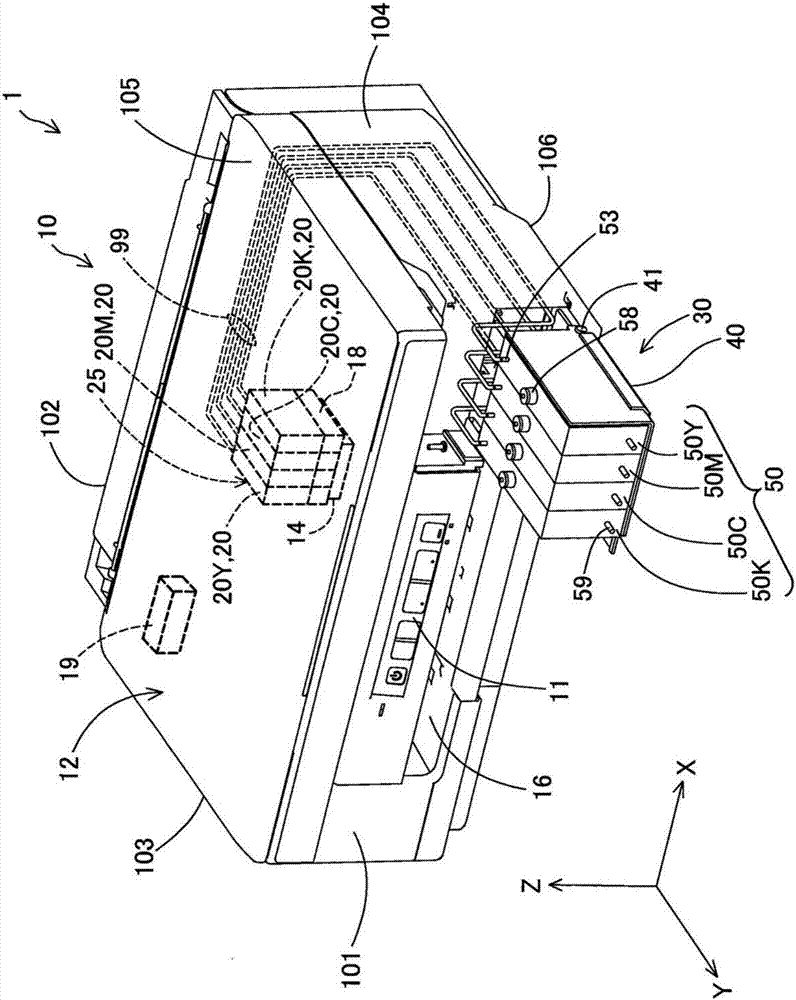

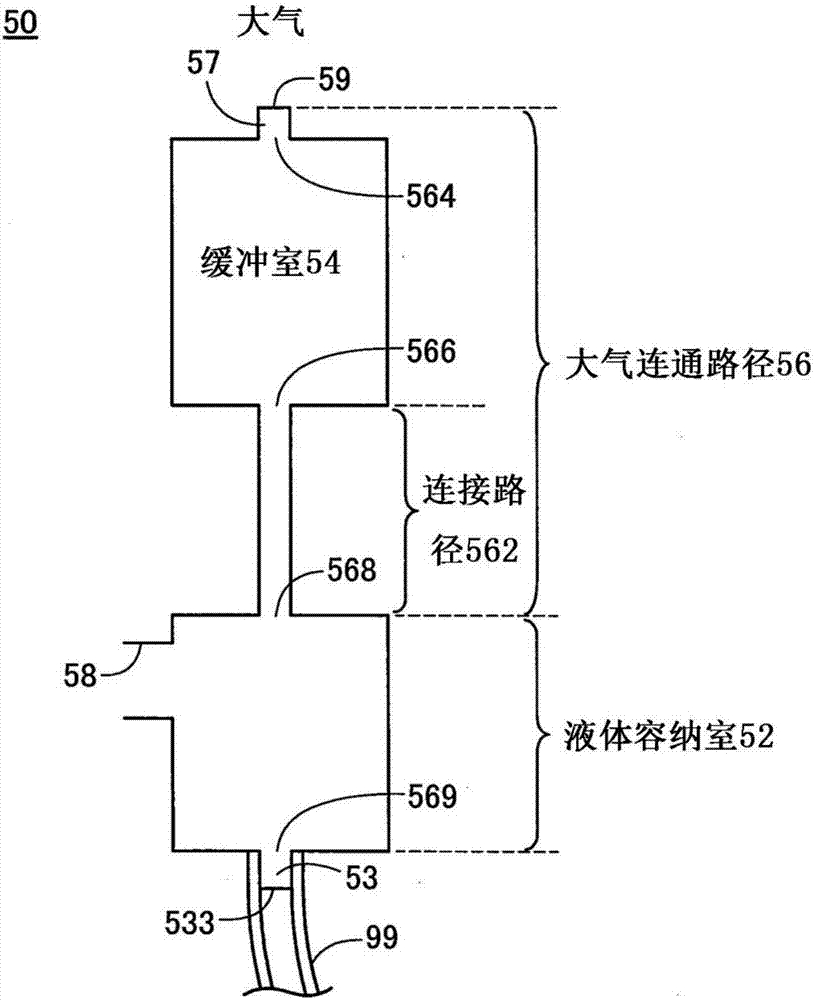

[0133] figure 1 and figure 2 It is a schematic diagram of the liquid ejection system 1 as the first embodiment of the present invention. figure 1 The appearance of the liquid ejection system 1 in use is shown. figure 2 The external appearance and part of the internal structure (dotted line) of the liquid ejection system 1 in the injected state are shown. exist figure 1 and figure 2 There are mutually orthogonal X-axis, Y-axis and Z-axis plotted in . The X-axis corresponds to the “width direction” of the printer 10 . Likewise, the Y axis corresponds to the “depth direction” of the printer 10 , and the Z axis corresponds to the “height direction” of the printer 10 . That is, the printer 10 is installed on a horizontal installation surface defined by the X-axis direction and the Y-axis direction. In addition, in figure 1 and figure 2 Herein, the +Z-axis direction (ie, the upper side of the paper) is also referred t...

no. 2 approach

[0208] Figure 9 It is a diagram conceptually showing a flow path from the atmosphere opening 59 of the liquid supply device 50 a to the liquid outlet 53 according to the second embodiment of the present invention. The liquid supply device 50a of the second embodiment differs from the liquid supply device 50 of the first embodiment in the number of buffer chambers 54a1 to 54a3 and the structure of the atmosphere communication path 56a. The other configurations of the liquid supply device 50 a are the same as those of the liquid supply device 50 , so the same reference numerals are assigned to the same configurations, and description thereof will be omitted.

[0209] In the liquid supply device 50a, three buffer chambers 54a1, 54a2, and 54a3 are provided in series in the middle of the atmosphere communication path 56a. The buffer chamber 54a1, the buffer chamber 54a2, and the buffer chamber 54a3 are arranged in this order from the upstream side toward the downstream side. Her...

no. 3 approach

[0236] D-1. Structure of Liquid Injection System:

[0237] Figure 11 as well as Figure 12 It is a schematic diagram of a liquid ejection system 1m as a third embodiment of the present invention. Figure 11 Indicates the appearance of the liquid injection system 1m, Figure 12 The external appearance and a part of the internal structure (dotted line) of the liquid ejection system 1m are shown. The liquid ejection system 1 m includes a printer 10 m, a liquid storage unit 30 m including a liquid storage chamber 50 m, and an air storage chamber 60 m. The printer 10m functions as a "liquid ejecting device". The liquid storage unit 30m (liquid storage chamber 50m) and the air storage chamber 60m function as a "liquid supply device".

[0238] Such as Figure 11 As shown, in the use state of the liquid ejection system 1m, the liquid storage unit 30m (liquid storage chamber 50m) is accommodated inside the printer 10m. Such as Figure 12 As shown, in the liquid supply state of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com