battery support structure

A technology for supporting structures and batteries, applied in structural parts, battery pack parts, battery/battery traction, etc., to achieve the effects of improving assembly accuracy, increasing diameter, and reducing manufacturing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

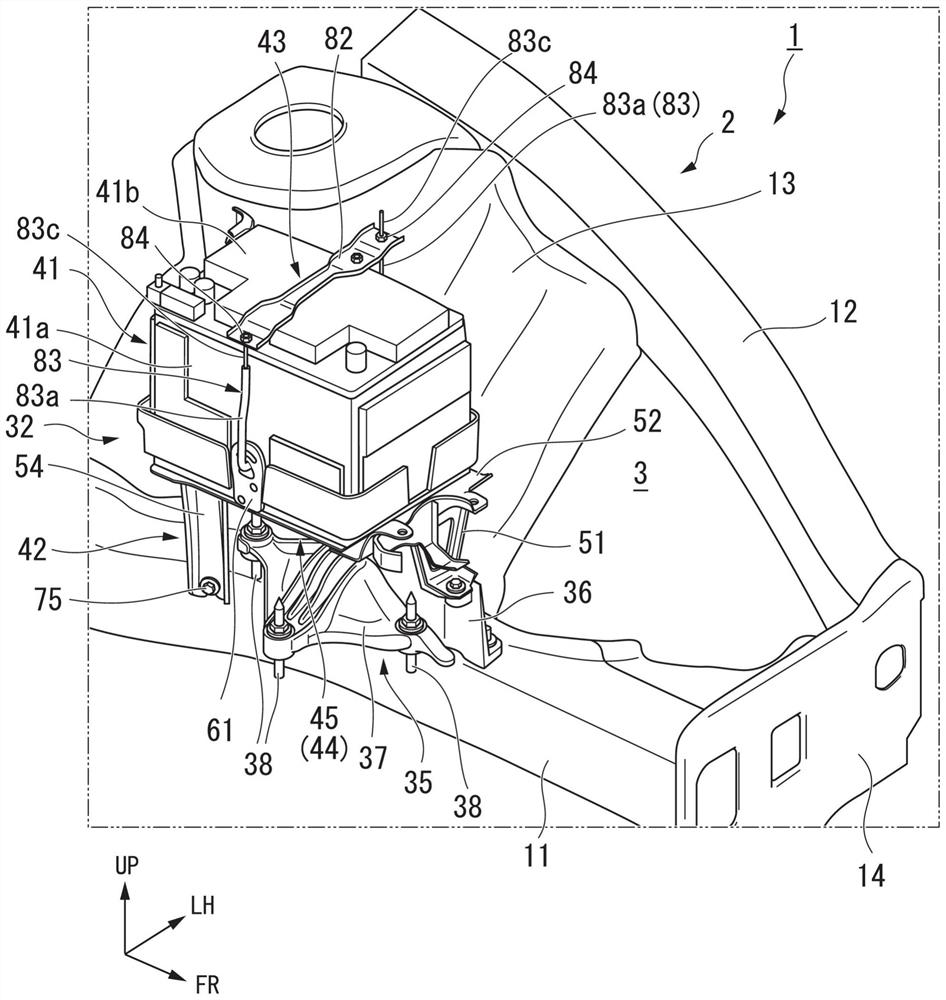

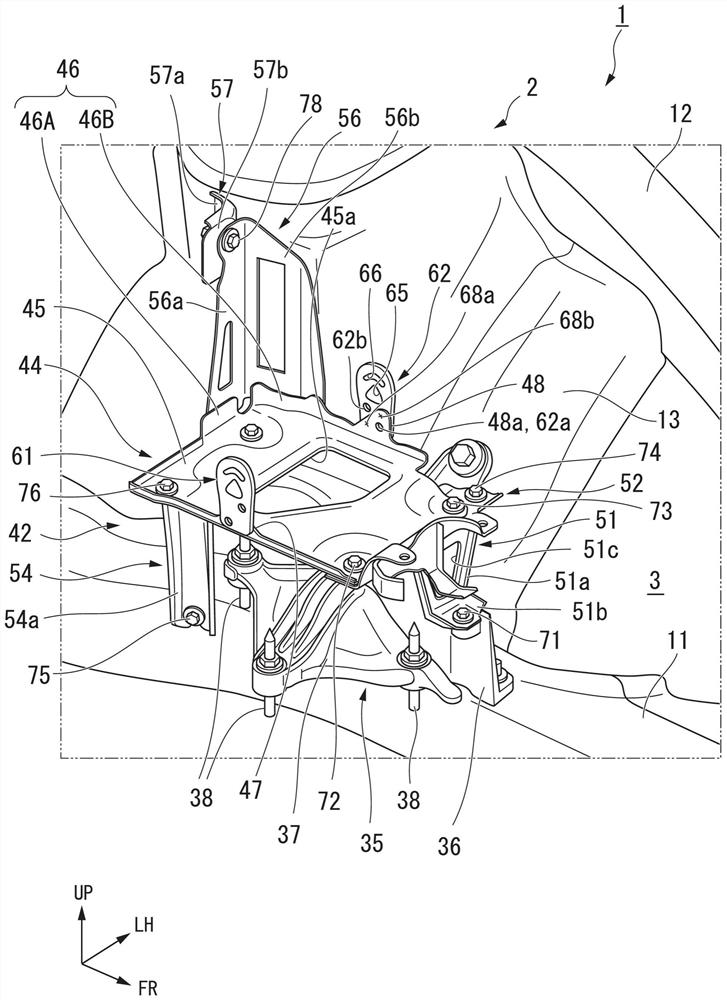

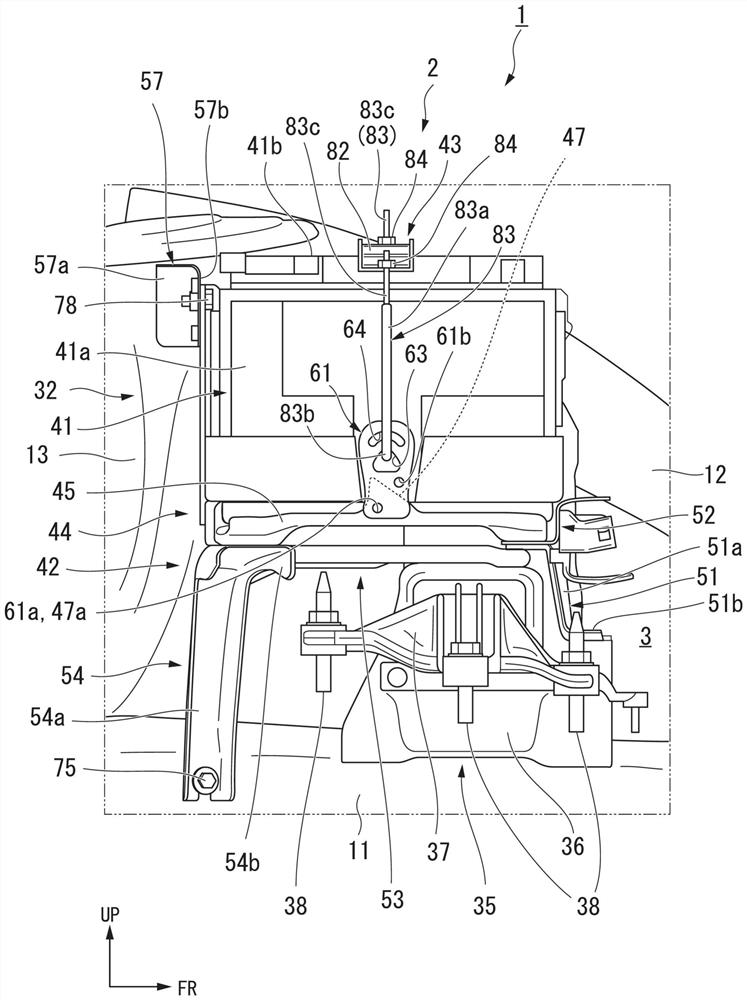

[0039] Embodiments of the present invention will be described below with reference to the drawings. Unless otherwise specified, directions such as front, rear, up, down, left, and right in the following description are the same as those of the vehicle 1 . In addition, in the drawing, an arrow UP indicates upward, an arrow FR indicates the front, and an arrow LH indicates the left.

[0040] figure 1 It is a perspective view of the battery support structure according to the embodiment viewed from the inside in the vehicle width direction.

[0041] Such as figure 1 As shown, in the vehicle 1 , an engine compartment 3 is formed in the front portion of the vehicle body 2 . The engine compartment 3 is framed by, for example, an instrument panel (not shown), a front side frame 11 , a subframe (not shown), an upper member 12 , a shock absorber housing 13 , and the like.

[0042] The front side frame 11 is arranged in the lower part of the engine compartment 3 on both sides in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com