Multifunctional pulp molding buffer pad and application thereof

A pulp molding and cushioning technology, applied in the direction of containers, containers, transportation and packaging to prevent mechanical damage, can solve the problems of rising costs, increased weight and cost of paper-plastic products, and thickening treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the drawings and embodiments:

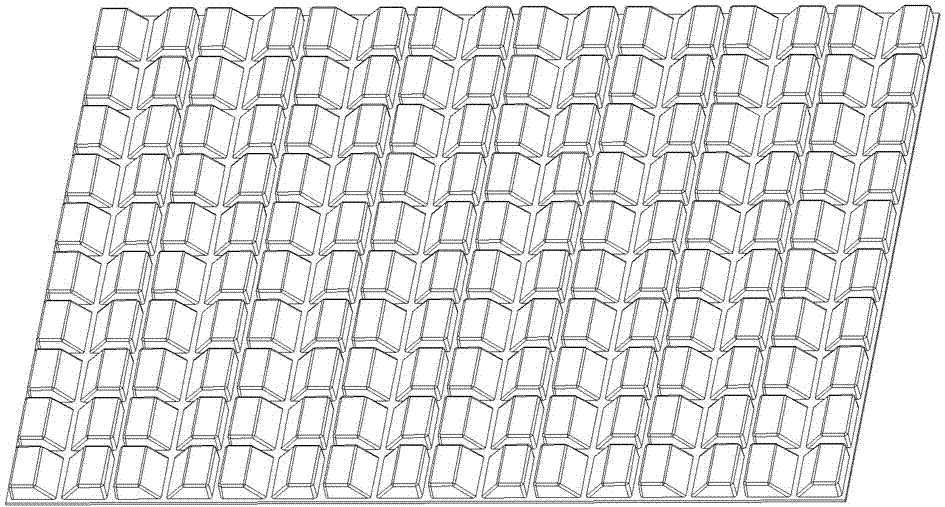

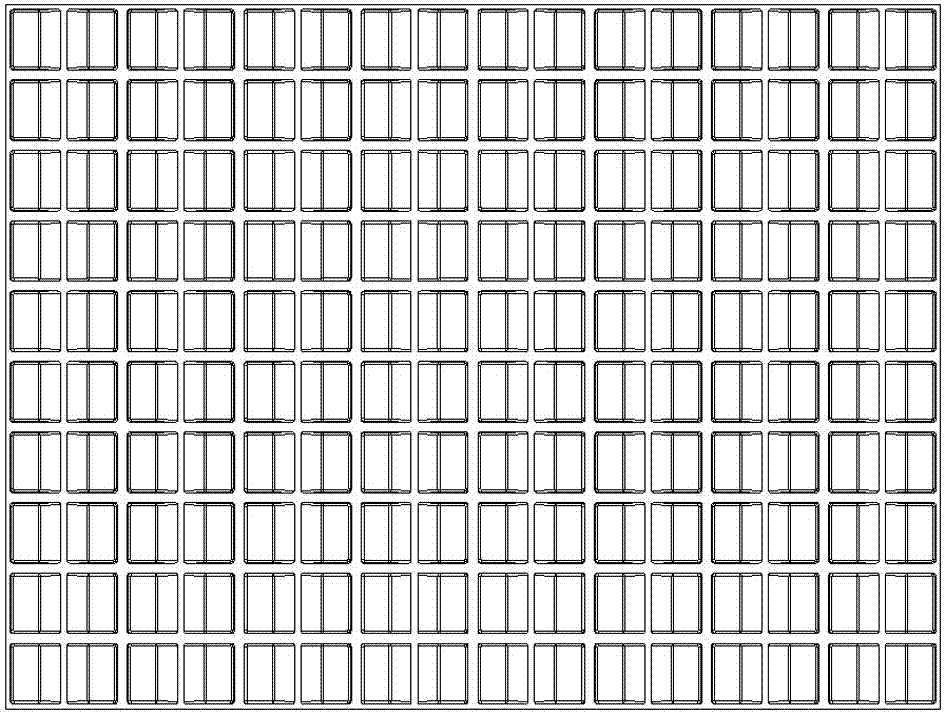

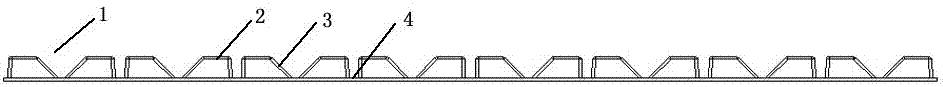

[0032] Example: see Figure 1 to Figure 4 As shown, a multifunctional pulp molded cushion pad is composed of a cushion unit 1 repeating an array structure along the transverse and longitudinal directions, and the cushion unit 1 is composed of a pair of cushion protrusions 2 molded from pulp. The connecting edge 4 at the periphery of the bottom of the protrusion 2 is formed, and the adjacent side surfaces of a pair of the buffer protrusions 2 are inclined surfaces 3. The arrangement direction of the inclined surfaces 3 makes the top surface of the buffer protrusion 2 smaller than the bottom surface of the buffer protrusion 2.

[0033] Among them, the repeating number of the buffer unit is set according to the mold forming requirements. Generally, the number of the buffer unit repeating in the transverse direction is not less than 6, and the number of repeating units in th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap