Paper folding method applicable to single-width perforated folded tissues

A technology of drawing paper and punching line, applied in the direction of folding thin materials, metal processing, thin material processing, etc., can solve the problems of increasing the production cost of enterprises, slow production speed, single product, etc., to improve production speed and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

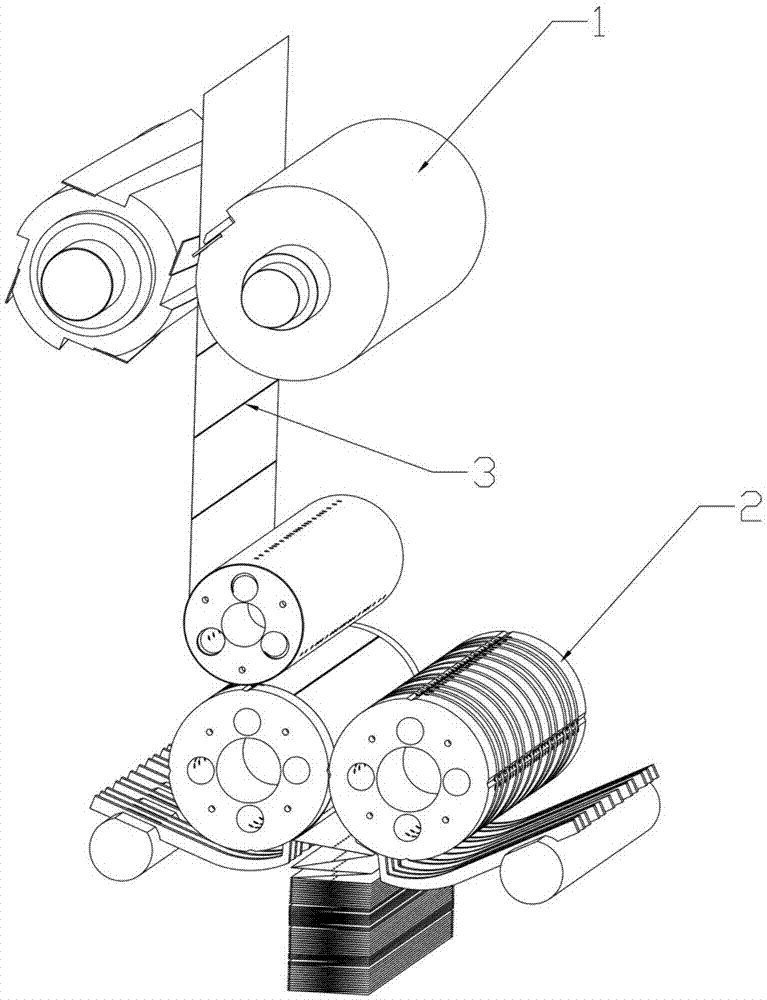

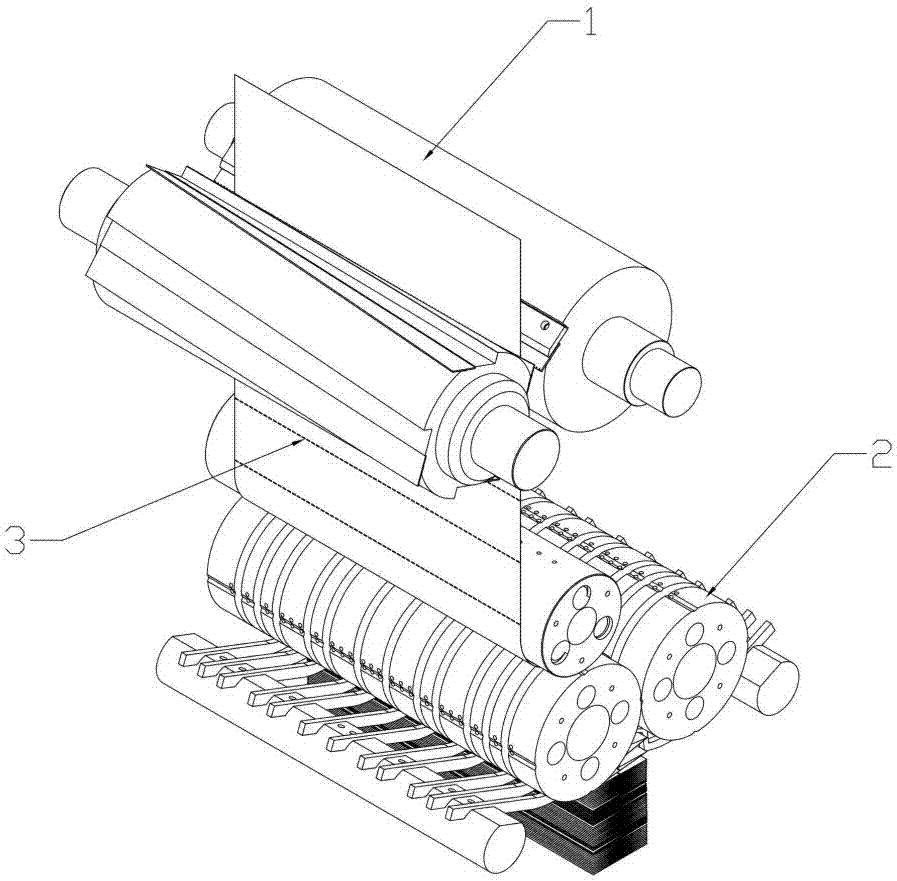

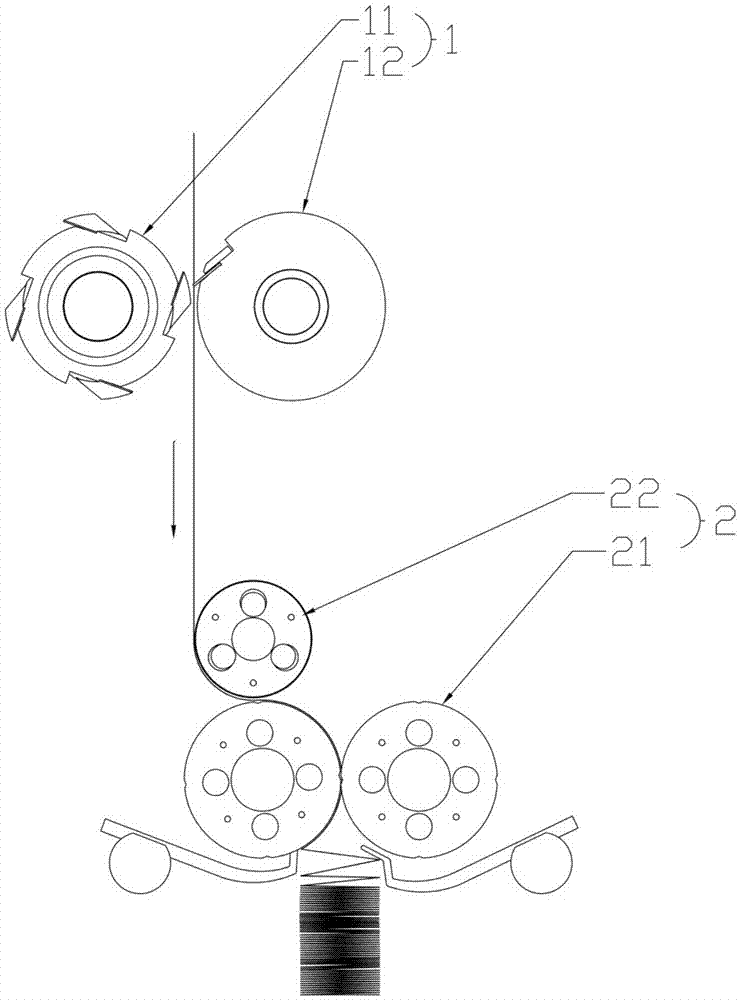

Method used

Image

Examples

Embodiment 1

[0030] See attached Figure 4 And attached Figure 5 As shown, in this embodiment, the folding line 4 coincides with the perforated line 3 in the gap, that is, the finished single layer of perforated and folded paper is one layer of paper 5 .

Embodiment 2

[0032] See attached Image 6 As shown, in this embodiment, a folding line 4 is formed between any two adjacent gap perforation lines 3, that is, one grid of paper 5 is folded once in the finished single-width perforated and folded paper, In this way, when the length dimension of one grid of paper 5 is increased, the width dimension of the finished single punched and folded paper does not need to be changed.

Embodiment 3

[0034] See attached Figure 7 As shown, in this embodiment, two folding lines 4 are formed between two adjacent gap perforation lines 3, that is, one grid of paper 5 is folded twice in the finished single-width perforated and folded paper. In this way, the length of each paper is not limited by the width of the finished single punched and folded paper.

[0035] In summary, this solution is described using the above three embodiments. By adopting the unilateral feeding method of single-width base paper, the production efficiency is greatly improved; by adjusting the distance between two adjacent gap perforation lines 3, each of the finished single-width perforated and folded paper is adjusted. The length and size of the grid paper is no longer limited by the size, and it can be properly selected according to the required size. There are 4 folding lines between any two adjacent gap punching lines 3, thereby realizing a single-width punching The folding paper machine is suitabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com