Die for mounting big-area GRG panel

A large-area, mold-based technology, applied in construction, building construction, etc., can solve the problems of large cumulative errors and low construction efficiency, and achieve the effects of reducing cumulative errors, improving construction efficiency, and improving construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

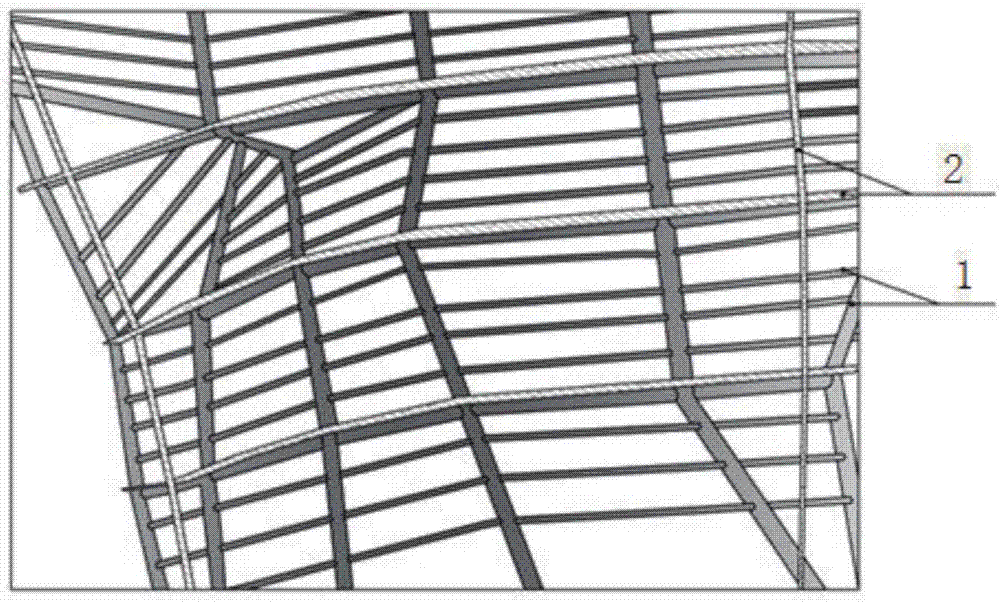

[0022] Such as figure 1 As shown, a mold for installing a large-area GRG panel includes a detachable mold 2 installed on the base steel structure 1 of the GRG panel. The mold 2 is spliced by multiple unit frames. A connecting piece 3 is provided, one end of the connecting piece 3 is fixedly connected to the base steel structure 1, and the other end is fixedly connected to the unit frame and can be disassembled.

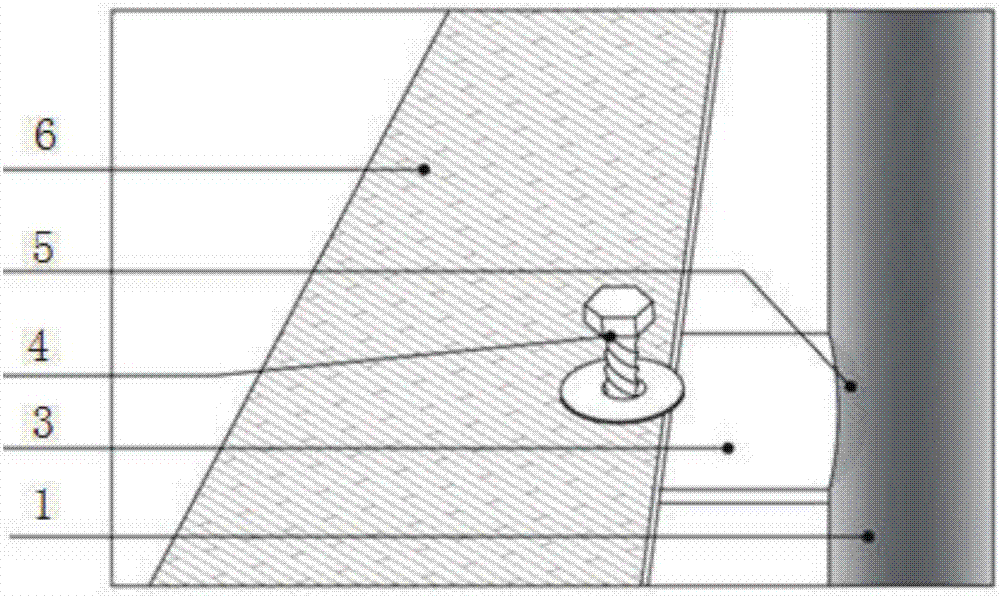

[0023] The unit frame of this embodiment is a plank frame 6 . The unit frame can be a plate structure that can achieve the same function, such as wood, fiberboard or plastic plate. On the one hand, the plate structure is used as a unit frame, and on the other hand, it is used as a positioning part for GRG panel installation, which effectively ensures the installation accuracy of GRG panels. The cumulative error is reduced.

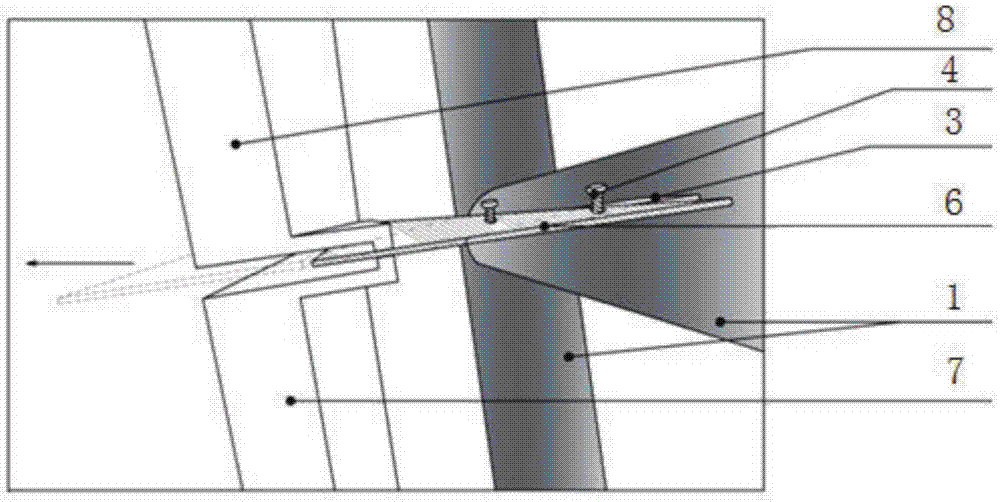

[0024] The example mold is installed as figure 2 , image 3 As shown, one end of the connecting piece 3 is welded on the base steel struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com