Double-hole parallel beam type six-dimensional force sensor

A six-dimensional force sensor and parallel beam technology, applied in the field of sensors, can solve the problems of large inter-dimensional coupling, large nonlinearity, and low sensitivity, and achieve the effects of small inter-dimensional coupling, good linearity, and low sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

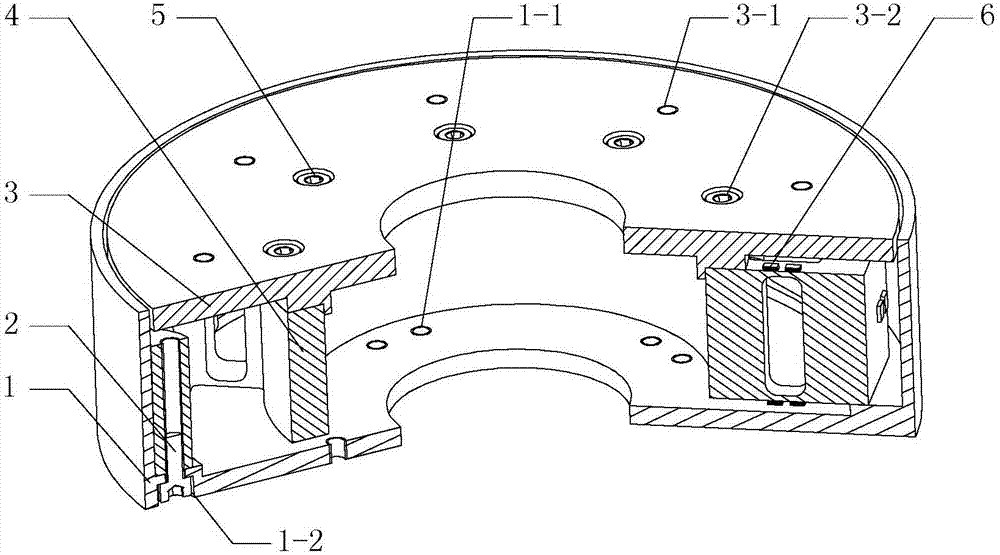

[0025] Specific embodiment one: reference Figure 1 to Figure 4 Specifically describing this embodiment, a dual-hole parallel beam type six-dimensional force sensor described in this embodiment includes: a housing 1, a plurality of lower end fixing screws 2, an upper end cover 3, an elastic body 4, a plurality of upper end fixing screws 5, and Multiple resistance strain gauges 6;

[0026] The shell 1 is in the shape of a barrel, a central through hole is opened in the center of the bottom surface of the shell 1, and the upper end cover 3 is in a circular ring shape.

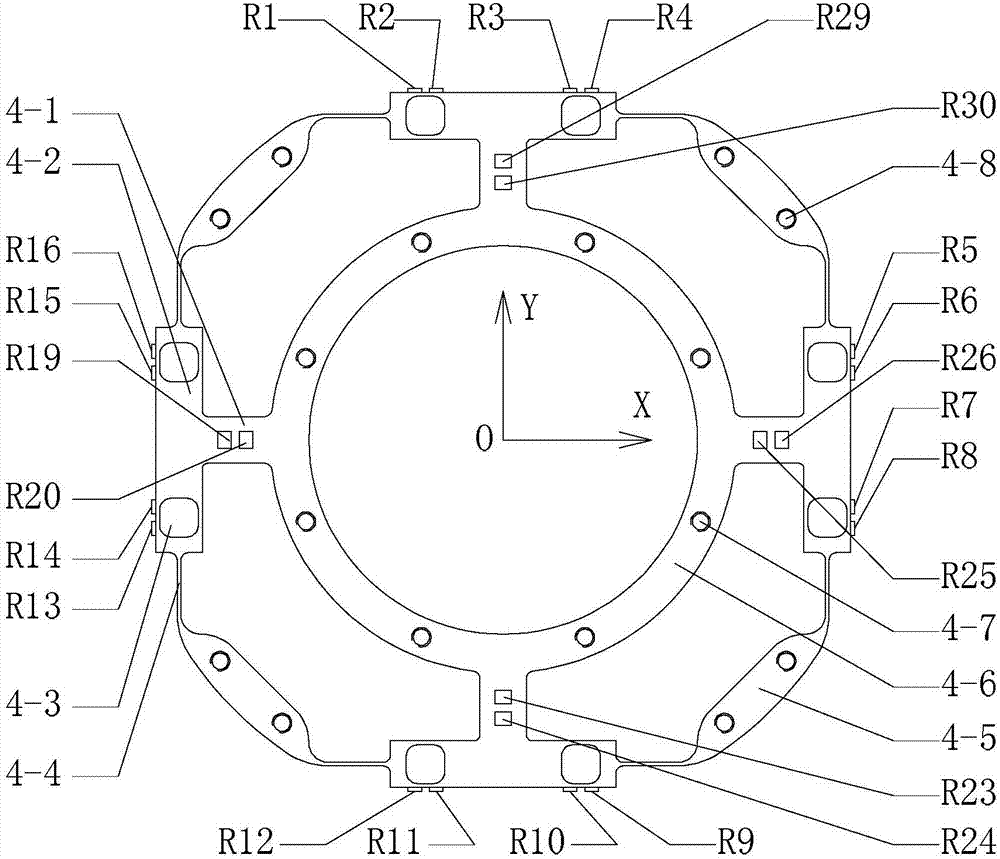

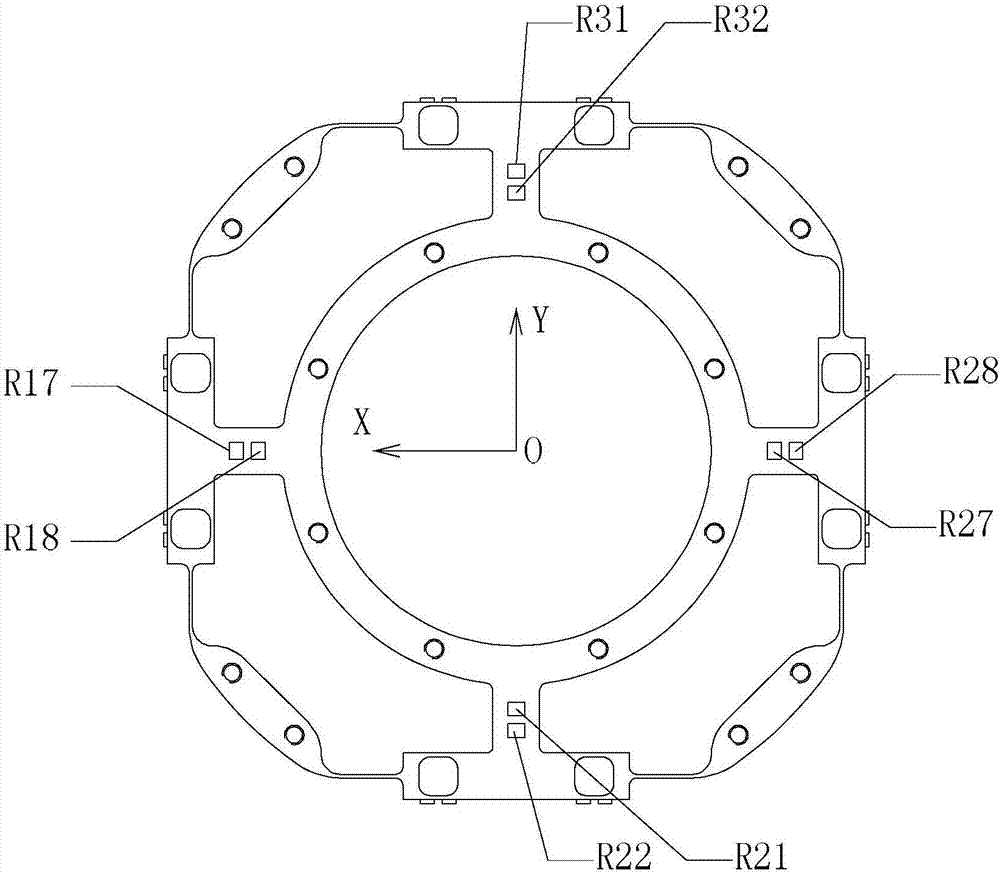

[0027] The elastic body 4 includes: four inner elastic beams 4-1, four outer elastic beams 4-2, eight floating beams 4-4, four fixed platforms 4-5 and loading platforms 4-6;

[0028] The loading platform 4-6 is cylindrical, one end of the four inner elastic beams 4-1 is fixed on the outside of the loading platform 4-6, and the four inner elastic beams 4-1 are evenly arranged on the outside of the loading platform 4-6, ...

Example Embodiment

[0033] Embodiment 2: This embodiment is a further description of a double-hole parallel beam type six-dimensional force sensor described in Embodiment 1. In this embodiment, there are 8 shell threaded holes 1 on the bottom surface of the shell 1 -1 and 8 shell through holes 1-2, the upper end cover 3 has 8 upper end cover threaded holes 3-1 and 8 upper end cover through holes 3-2,

[0034] 8 shell threaded holes 1-1 in pairs form a total of 4 sets of threaded hole groups, the 4 sets of threaded holes are evenly arranged along the circumference of the shell, and the adjacent two sets of threaded hole sets are separated by 90°, 8 A total of 4 sets of through hole groups are formed in two sets of two through-holes of the shell, and the four sets of through holes are evenly arranged along the circumferential direction of the shell, and the adjacent two sets of through hole sets are separated by 90°, 4 sets The radius of the circumference of the threaded hole group is smaller than the...

Example Embodiment

[0037] Specific embodiment three: this embodiment is a further description of a double-hole parallel beam type six-dimensional force sensor described in specific embodiment two. In this embodiment, the loading platform 4-6 is provided with 8 platform threads Holes 4-7, the 8 screw holes 4-7 of the carrier are respectively aligned with the 8 upper end cover through holes 3-2, and the upper fixing screw 5 passes through the upper end cover through holes 3-2 and threaded holes 4-7. Threaded connection,

[0038] Each fixing table 4-5 is provided with two fixing table threaded holes 4-8. The 8 fixing table threaded holes 4-8 are directly opposite to the 8 shell through holes 1-2, and the lower end fixing screws 2 pass through. The threaded connection is realized through the shell through hole 1-2 and the screw hole 4-8 of the fixing table.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com