Small asphalt mixture mixing equipment

A technology of asphalt mixture and equipment, which is applied in the field of small asphalt mixture mixing equipment, and can solve the problems of incomplete mixing and inconvenient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

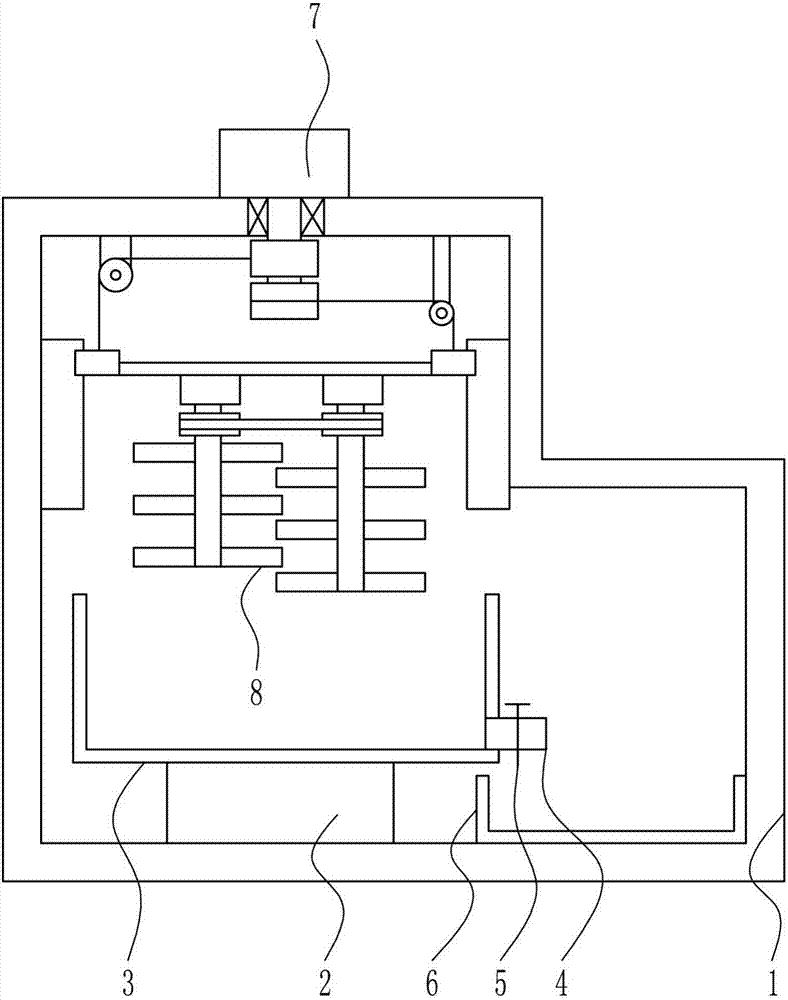

[0029] A small asphalt mixing plant, such as Figure 1-5 As shown, it includes a mounting frame 1, a support rod 2, a frame body 3, a discharge pipe 4, a first valve 5, a collection frame 6, a lifting device 7 and a stirring device 8, and a support rod is provided on the left side of the bottom of the mounting frame 1 2. A frame body 3 is provided on the top of the support rod 2, a discharge pipe 4 is provided at the lower part of the right wall of the frame body 3, a first valve 5 is provided on the discharge pipe 4, and the inner bottom of the installation frame 1 on the lower right side of the discharge pipe 4 is placed There is a collection frame 6, and the top of the installation frame 1 is provided with a lifting device 7 and a stirring device 8, and the stirring device 8 is installed at the bottom of the lifting device 7.

Embodiment 2

[0031] A small asphalt mixing plant, such as Figure 1-5 As shown, it includes a mounting frame 1, a support rod 2, a frame body 3, a discharge pipe 4, a first valve 5, a collection frame 6, a lifting device 7 and a stirring device 8, and a support rod is provided on the left side of the bottom of the mounting frame 1 2. A frame body 3 is provided on the top of the support rod 2, a discharge pipe 4 is provided at the lower part of the right wall of the frame body 3, a first valve 5 is provided on the discharge pipe 4, and the inner bottom of the installation frame 1 on the lower right side of the discharge pipe 4 is placed There is a collection frame 6, and the top of the installation frame 1 is provided with a lifting device 7 and a stirring device 8, and the stirring device 8 is installed at the bottom of the lifting device 7.

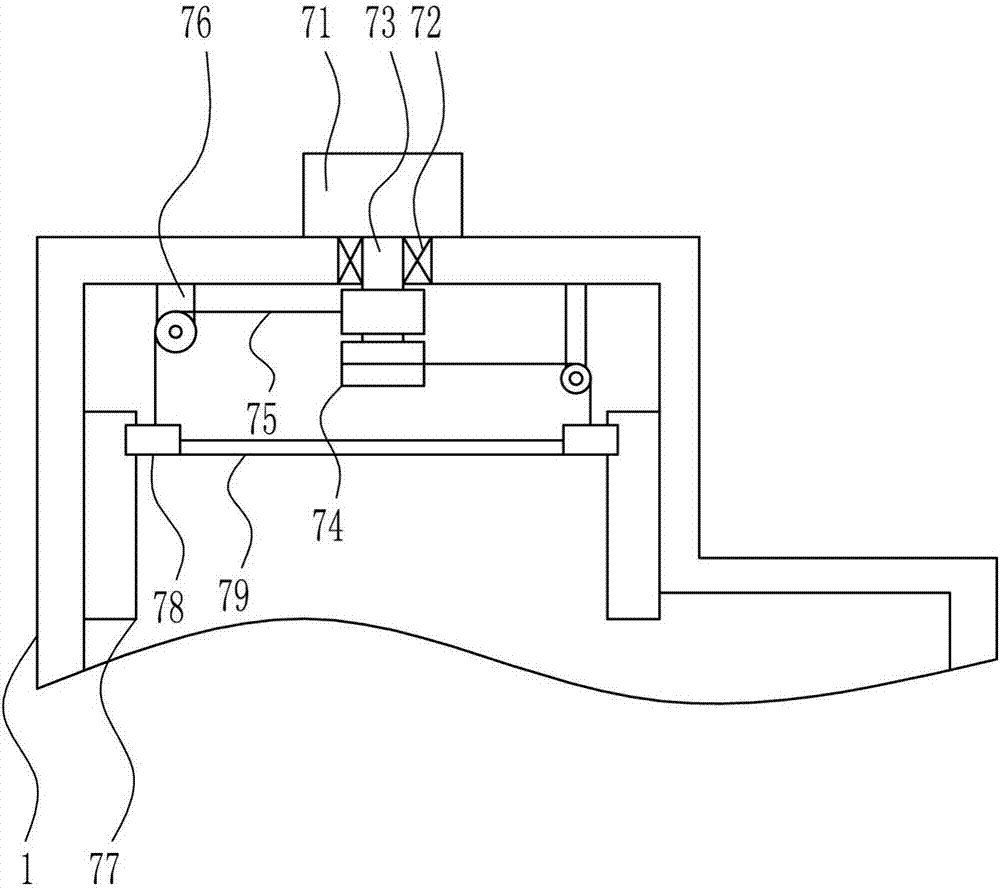

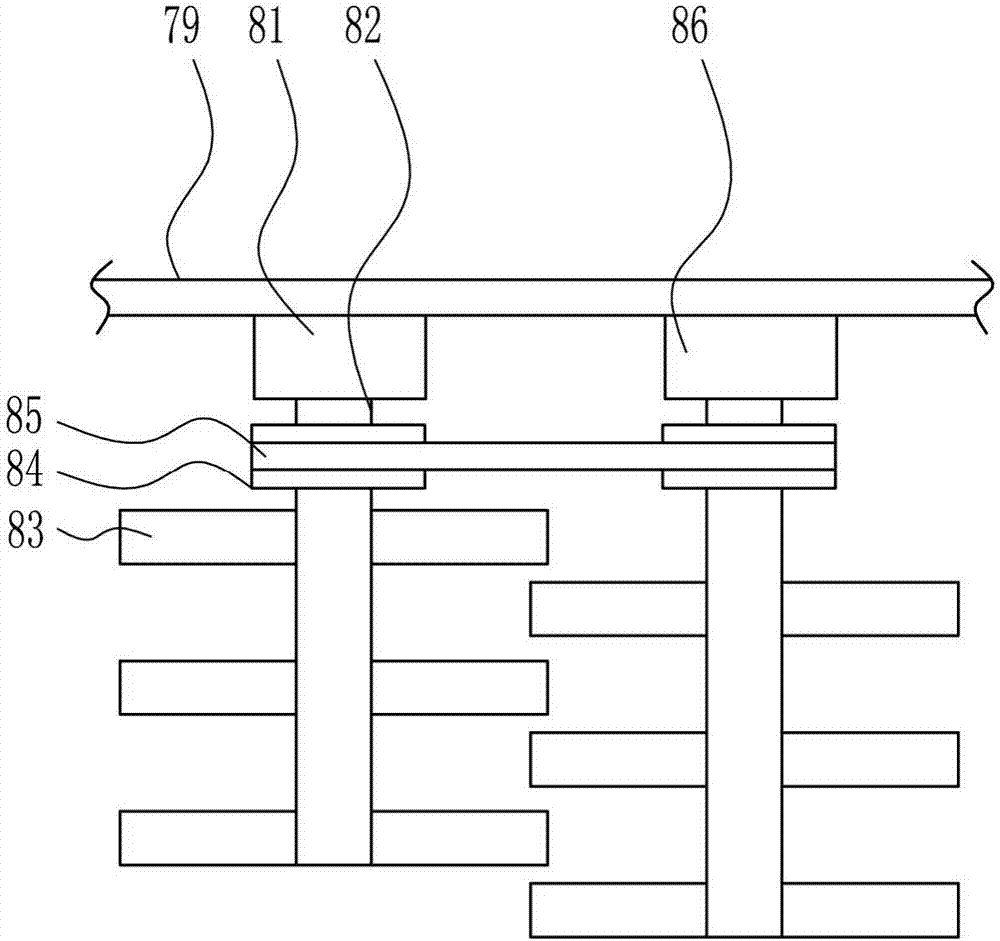

[0032] The lifting device 7 includes a first motor 71, a first bearing 72, a first rotating shaft 73, a reel 74, a rope 75, a fixed pulley 76, a sli...

Embodiment 3

[0034] A small asphalt mixing plant, such as Figure 1-5As shown, it includes a mounting frame 1, a support rod 2, a frame body 3, a discharge pipe 4, a first valve 5, a collection frame 6, a lifting device 7 and a stirring device 8, and a support rod is provided on the left side of the bottom of the mounting frame 1 2. A frame body 3 is provided on the top of the support rod 2, a discharge pipe 4 is provided at the lower part of the right wall of the frame body 3, a first valve 5 is provided on the discharge pipe 4, and the inner bottom of the installation frame 1 on the lower right side of the discharge pipe 4 is placed There is a collection frame 6, and the top of the installation frame 1 is provided with a lifting device 7 and a stirring device 8, and the stirring device 8 is installed at the bottom of the lifting device 7.

[0035] The lifting device 7 includes a first motor 71, a first bearing 72, a first rotating shaft 73, a reel 74, a rope 75, a fixed pulley 76, a slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com