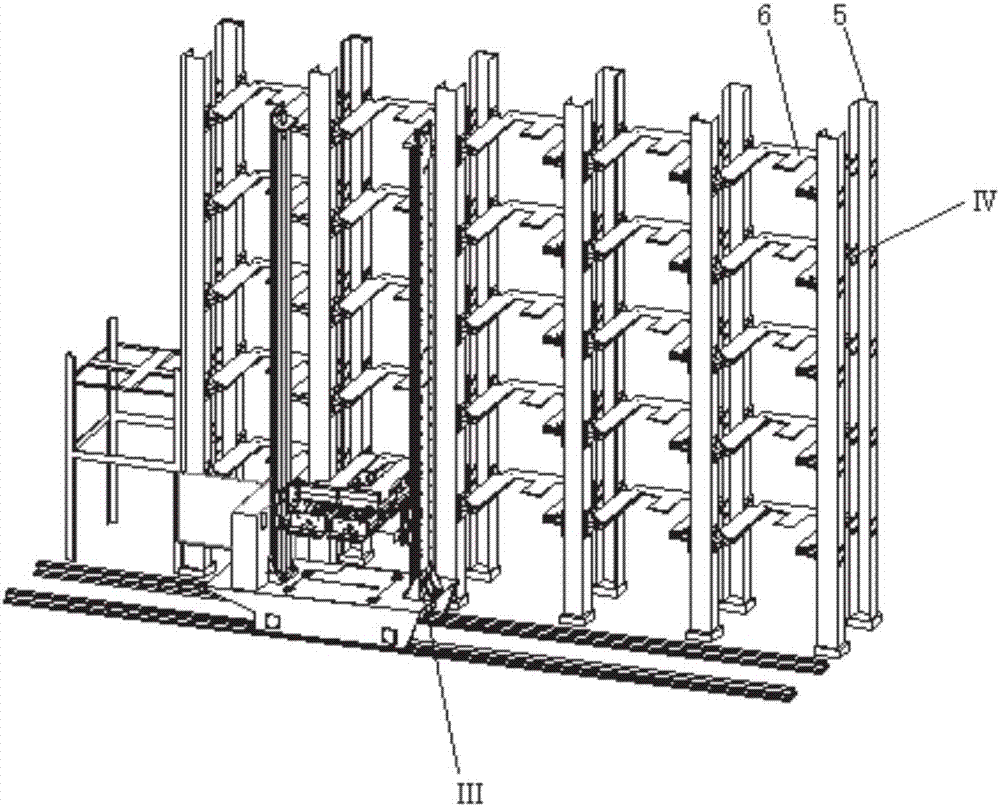

Automated warehouse

An automated warehouse and drive mechanism technology, applied in the field of warehouses, can solve the problems of limited lifting height of forklifts, limited height of warehouse shelves, and low utilization of warehouse space, so as to increase capacity, facilitate cargo management, and improve handling efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0064] The difference between this embodiment and embodiment 1 is:

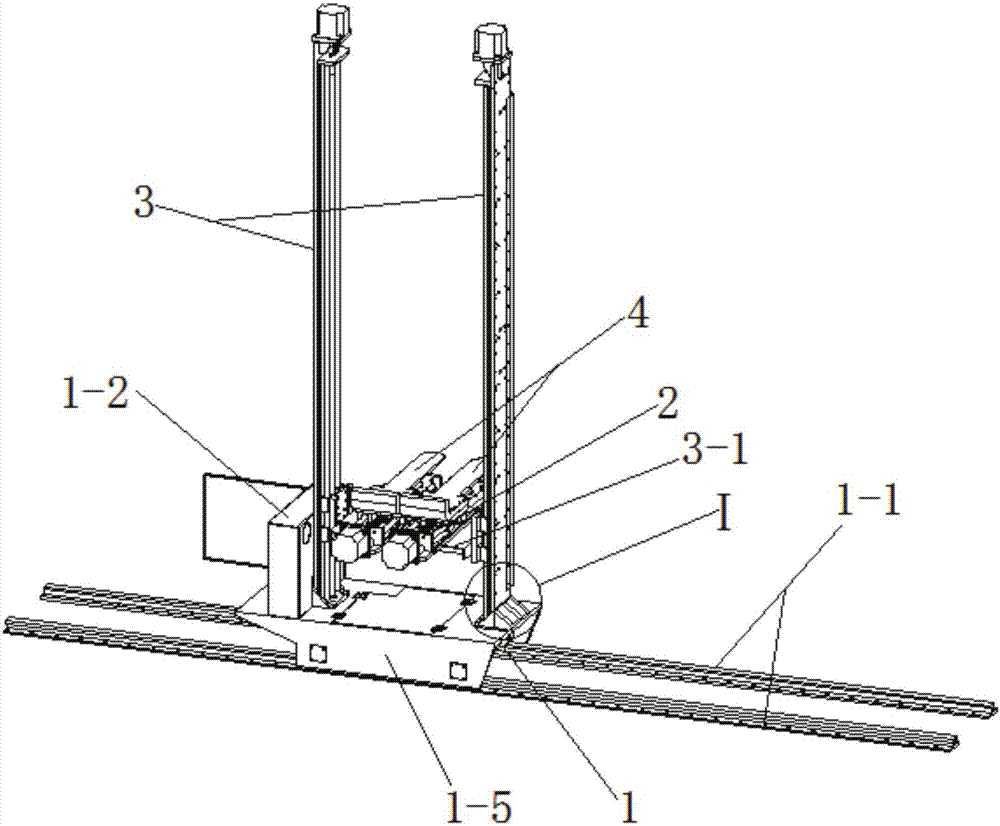

[0065] see Figure 14 , the X-axis guide rail includes two parallel first walking guide rails 1-6, and a rack assembly is provided in the middle of the first walking guide rail 1-6, and the rack assembly includes a rack guide rail 1-8 and a rack The first driving gear 1-7 matched with the guide rail 18; the X-axis driving mechanism includes a first X-axis driving motor fixed on the trolley, and the power output shaft of the first X-axis driving motor is connected with the first driving gear 1 -7 is fixedly connected; both sides of the bottom of the trolley are connected to the first walking guide rail 1-6 through sliders. By setting the rack assembly, the motor drives the first driving gear 1-7 to move on the rack guide rail 1-8, so that the trolley 1-5 slides on the first running guide rail 1-6.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap