Super-hydrophobic stain-resistant multicolour coating and preparation method thereof

A multi-colored, super-hydrophobic technology, applied in multi-color effect coatings, anti-fouling/underwater coatings, coatings, etc., can solve problems such as insufficient stain resistance, achieve improved stain resistance, and huge market development potential Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Example 1: Preparation of a super-hydrophobic stain-resistant colorful paint

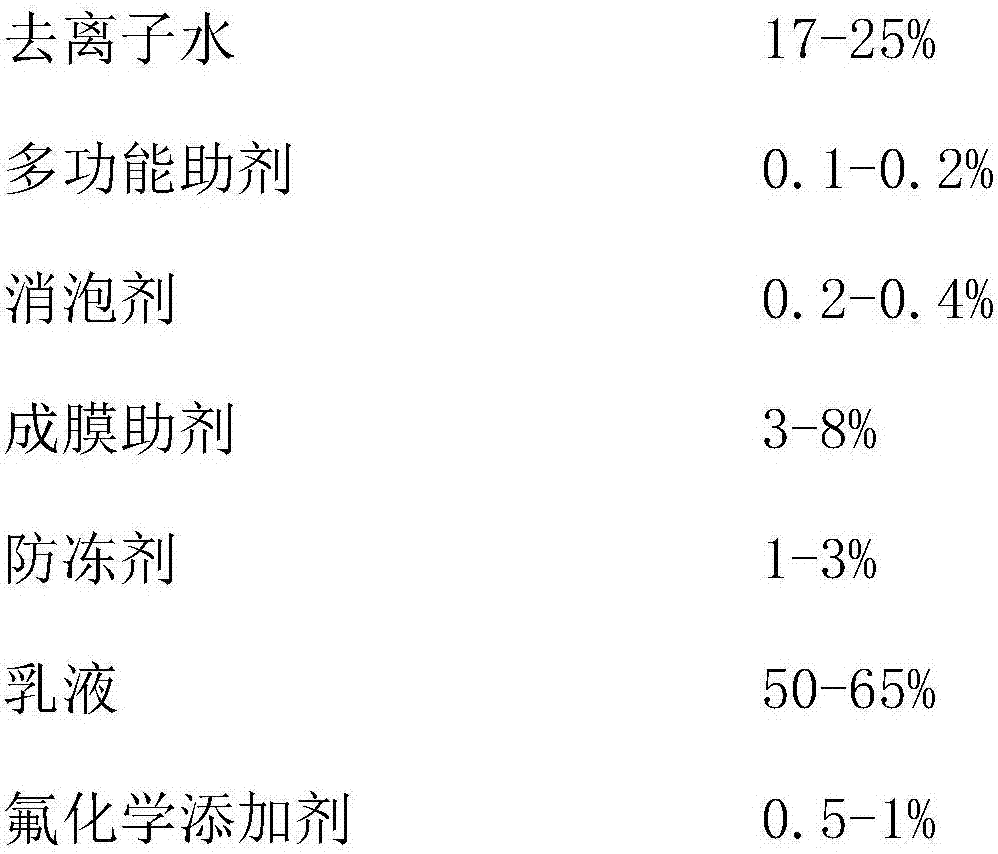

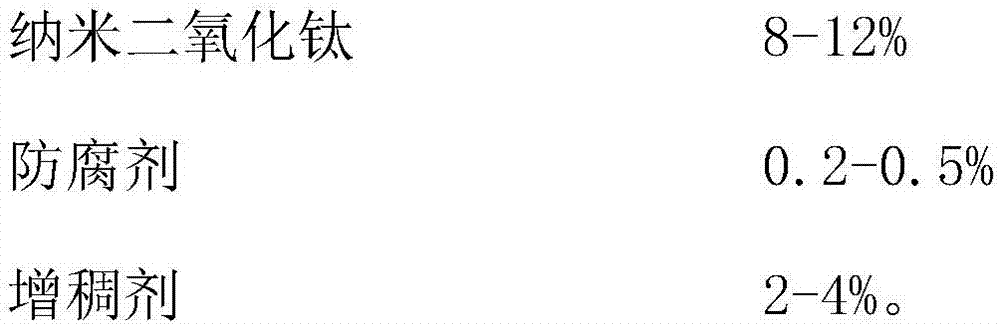

[0056] Table 1 Example 1-3 Super-hydrophobic anti-staining multi-color paint formula table (w / w%)

[0057]

[0058]

[0059] The raw material formula is shown in Table 1, where:

[0060] The protective colloidal salt is LAPONITE-S 482; the multifunctional auxiliary is 2-amino-2methyl-1-propanol; the dispersive wetting agent is an ammonium salt dispersing wetting agent; the defoaming agent The agent is a mineral oil defoamer; the film-forming aid is 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate; the antifreeze is ethylene glycol; the emulsion It is a pure acrylic emulsion; the nano TiO 2 TiO with 30-100nm surface modified by fluorosilane 2 Nano particles; the preservative is 2-methyl-4-isothiazolin-2-methyl-4-isothiazolin-3-one; the thickener is a polyurethane thickener.

[0061] Preparation:

[0062] Weigh each component raw material according to weight percentage.

[0063] Preparation of protective...

Embodiment 2

[0073] Example 2: Preparation of a super-hydrophobic and stain-resistant colorful paint

[0074] The raw material formula is shown in Table 1, where:

[0075] The protective colloidal salt is a mixture of LAPONITE-RDS and LAPONIE-RD; the multifunctional auxiliary agent is 2-amino-2methyl-1-propanol; the dispersing wetting agent is a potassium salt dispersing wetting agent The defoaming agent is a mixture of mineral oil defoamers and silicone defoamers; the film-forming aid is 2,2,4-trimethyl-1,3-pentanediol monoisobutyl Acid ester; the antifreeze is ethylene glycol; the emulsion is a silicon-modified acrylic emulsion; the nano TiO 2 TiO with 30-100nm surface modified by fluorosilane 2 Nano particles; the preservative is formaldehyde; the thickener is an alkali swelling thickener.

[0076] The preparation method is the same as in Example 1.

[0077] Experimental effect:

[0078] After the finished product prepared in Example 2 is sprayed and dried, the contact angle between the surface...

Embodiment 3

[0079] Example 3: Preparation of a super-hydrophobic stain-resistant colorful paint

[0080] The raw material formula is shown in Table 1, where:

[0081] The protective colloidal salt is LAPONITE-RDS; the multifunctional auxiliary agent is 2-amino-2methyl-1-propanol; the dispersing wetting agent is an ammonium salt dispersing wetting agent; the defoaming agent It is a mineral oil defoamer; the film-forming aid is 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate; the antifreeze is ethylene glycol; the emulsion is Mixing of pure acrylic emulsion and silicon modified acrylic emulsion; the nano TiO 2 TiO with 30-100nm surface modified by fluorosilane 2 Nano particles; the preservative is 2-methyl-4-isothiazolin-2-methyl-4-isothiazolin-3-one, 5-chloro-2-methyl-4isothiazolin-3- Mixing of ketones; the thickener is a mixture of polyurethane thickener and alkali swelling thickener.

[0082] The preparation method is the same as in Example 1.

[0083] Experimental effect:

[0084] After the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com