Self-cleaning coating and preparation method thereof

A self-cleaning and coating technology, applied in the field of coatings, can solve the problems that the exterior walls are easy to be pasted or printed advertisements, affect the appearance of buildings, and the coating elasticity is easy to age. It achieves high hydrophobicity and self-cleaning characteristics, excellent self-cleaning Cleaning ability, effect of low surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

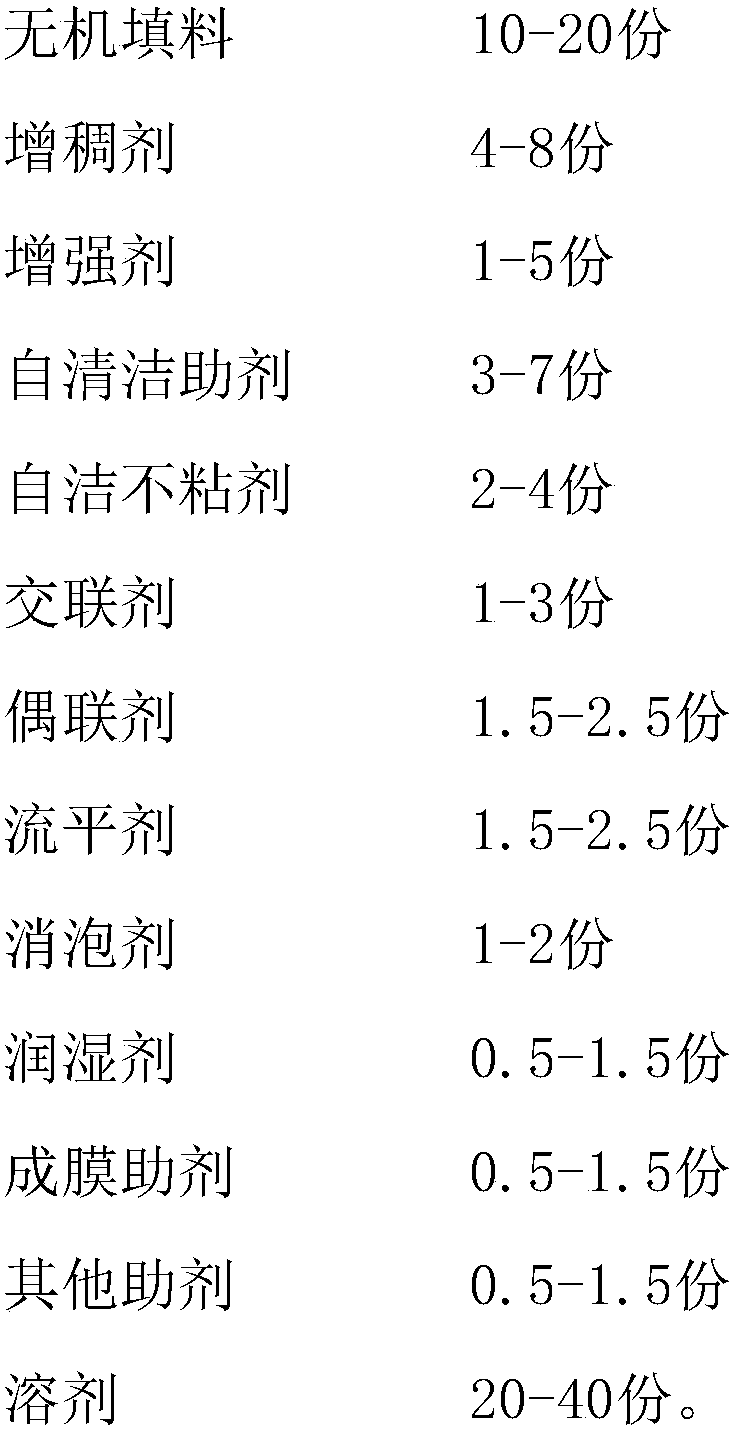

[0047] A self-cleaning paint, comprising the following raw materials in parts by weight:

[0048]

[0049] The fluorocarbon resin is a silicone modified fluorocarbon resin.

[0050] The inorganic filler is a mixture composed of modified nano kaolin, modified nano zirconium powder, modified calcium sulfate whiskers and rare earth mixture in a weight ratio of 0.4:0.8:1:0.2.

[0051] The thickener is a mixture of methyl cellulose, hydroxyethyl cellulose or hydroxypropyl methyl cellulose in a weight ratio of 1:0.5:1; the reinforcing agent is made of phenolic fiber, glass fiber and silicon A mixture of acid aluminum fibers in a weight ratio of 0.5:1.5:1.

[0052] The self-cleaning aid is a mixture of nano-titanium dioxide sol, silicon dioxide solution and nano-antimony-doped tin dioxide in a weight ratio of 0.4:1:0.8; the self-cleaning non-stick agent is composed of chlorinated paraffin, white oil and naphthenic oil in a weight ratio of 1:0.8:1.4.

[0053] The crosslinking agen...

Embodiment 2

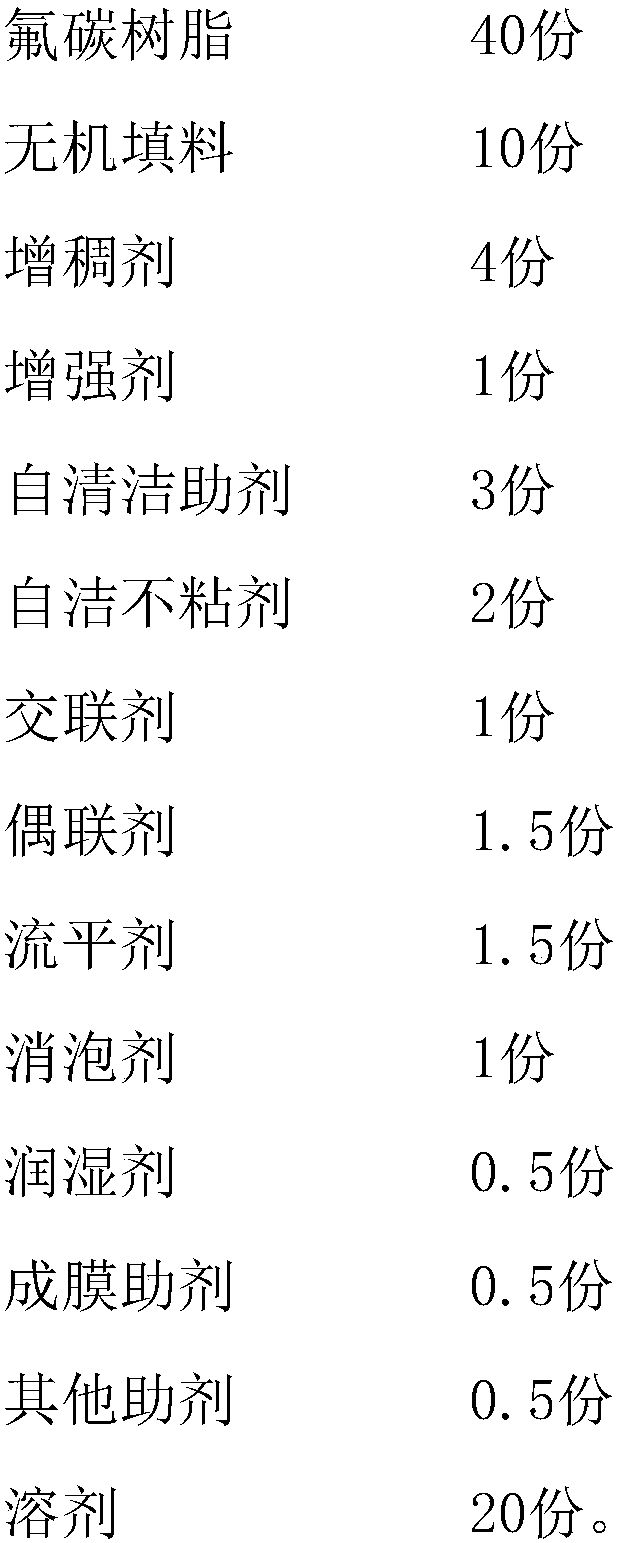

[0059] A self-cleaning paint, comprising the following raw materials in parts by weight:

[0060]

[0061] The fluorocarbon resin is a silicone modified fluorocarbon resin.

[0062] The inorganic filler is a mixture composed of modified nano kaolin, modified nano zirconium powder, modified calcium sulfate whiskers and rare earth mixture in a weight ratio of 0.5:0.9:1:0.3.

[0063] The thickener is a mixture of methylcellulose, hydroxyethylcellulose or hydroxypropylmethylcellulose in a weight ratio of 1.2:0.8:1; the reinforcing agent is made of phenolic fiber, glass fiber and silicon A mixture of acid aluminum fibers in a weight ratio of 0.8:1.8:1.

[0064] The self-cleaning aid is a mixture of nano-titanium dioxide sol, silicon dioxide solution and nano-antimony-doped tin dioxide in a weight ratio of 0.5:1:0.9; the self-cleaning non-stick agent is composed of chlorinated paraffin, white oil and naphthenic oil in a weight ratio of 1:0.9:1.6.

[0065] The crosslinking agen...

Embodiment 3

[0071] A self-cleaning paint, comprising the following raw materials in parts by weight:

[0072]

[0073]

[0074] The fluorocarbon resin is a silicone modified fluorocarbon resin.

[0075] The inorganic filler is a mixture composed of modified nano kaolin, modified nano zirconium powder, modified calcium sulfate whiskers and rare earth mixture in a weight ratio of 0.6:1:1:0.4.

[0076] The thickener is a mixture of methylcellulose, hydroxyethylcellulose or hydroxypropylmethylcellulose in a weight ratio of 1.5:1:1; the reinforcing agent is made of phenolic fiber, glass fiber and silicon A mixture of acid aluminum fibers in a weight ratio of 1:2:1.

[0077] The self-cleaning aid is a mixture of nano-titanium dioxide sol, silicon dioxide solution and nano-antimony-doped tin dioxide in a weight ratio of 0.6:1:1; the self-cleaning non-stick agent is composed of chlorinated paraffin, white oil and naphthenic oil in a weight ratio of 1:1:1.8.

[0078] The crosslinking agen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com