Construction method applied to deviation rectification of sea silt soil square pile groups

A construction method, earth square technology, applied in the direction of foundation structure engineering, construction, etc., can solve the problems of gradual transition force and passive pressure relief of the pile body, pile foundation deflection, etc., to achieve gradual transition force and passive The effects of pressure relief, enhanced bearing capacity of pile groups, and high efficiency of deviation correction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The implementation process of the present invention will be described in detail below in conjunction with the accompanying drawings.

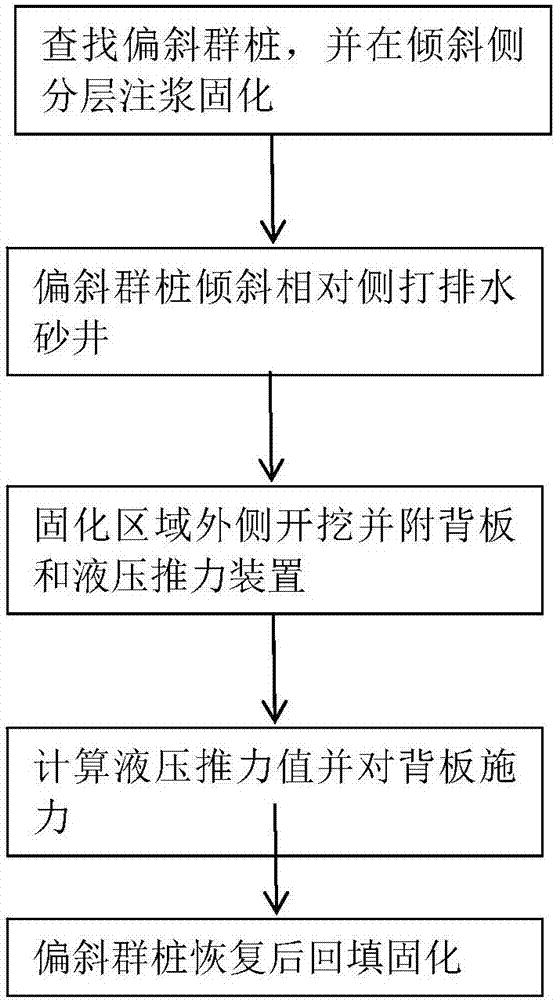

[0033] A construction method for rectifying deviation of square piles in sea silt soil, such as figure 1 shown, including the following steps:

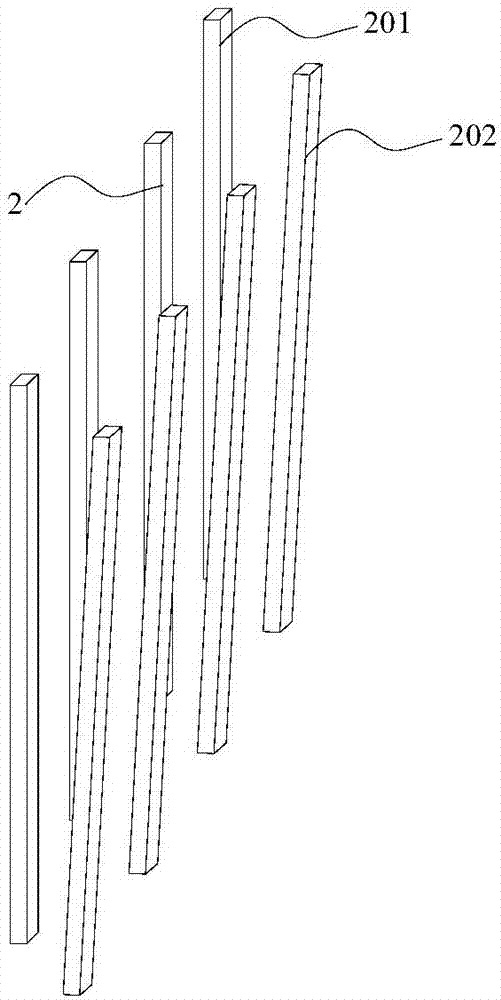

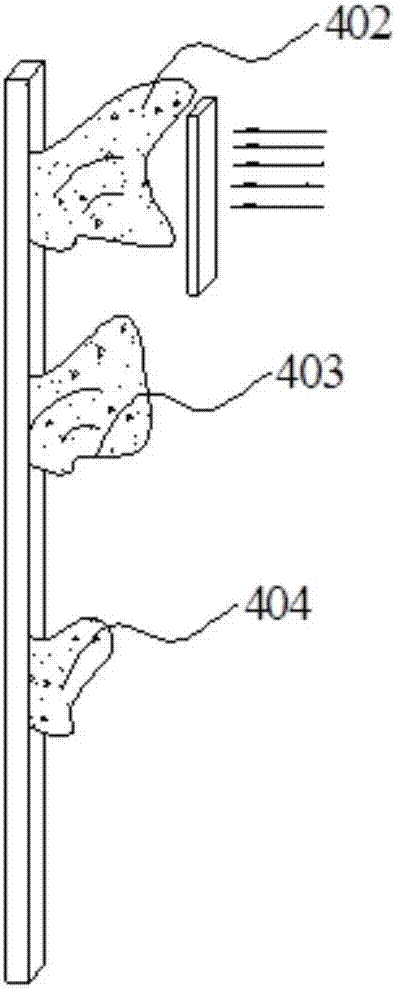

[0034] 1. At first, search for skewed square piles, and use a plurality of adjacent square piles with the same skewed direction as a group of skewed piles 202 (such as figure 2 ), measuring the offset displacement X of pile group pile top 0 and offset tilt angle φ 0 , and then layer-by-layer grouting on the inclined side of the skewed pile group 202 is solidified. The details are as follows: on the inclined side of the skewed pile group, the distance from the pile foundation to the pile foundation is 3 times the length of the side of the square pile. The length of the grouting hole is 1 / 3 of the length of the square pile. image 3 ) into the solidified sea silt slurry, pre-coagulated for 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com