Second-class absorption heat pump

An absorption heat pump and absorber technology, which is applied in the direction of adsorption machines, energy-saving heating/cooling, lighting and heating equipment, etc., can solve the problems of small temperature difference between inlet and outlet, large investment cost, and complicated operation, so as to improve COP, Effect of reducing energy waste rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

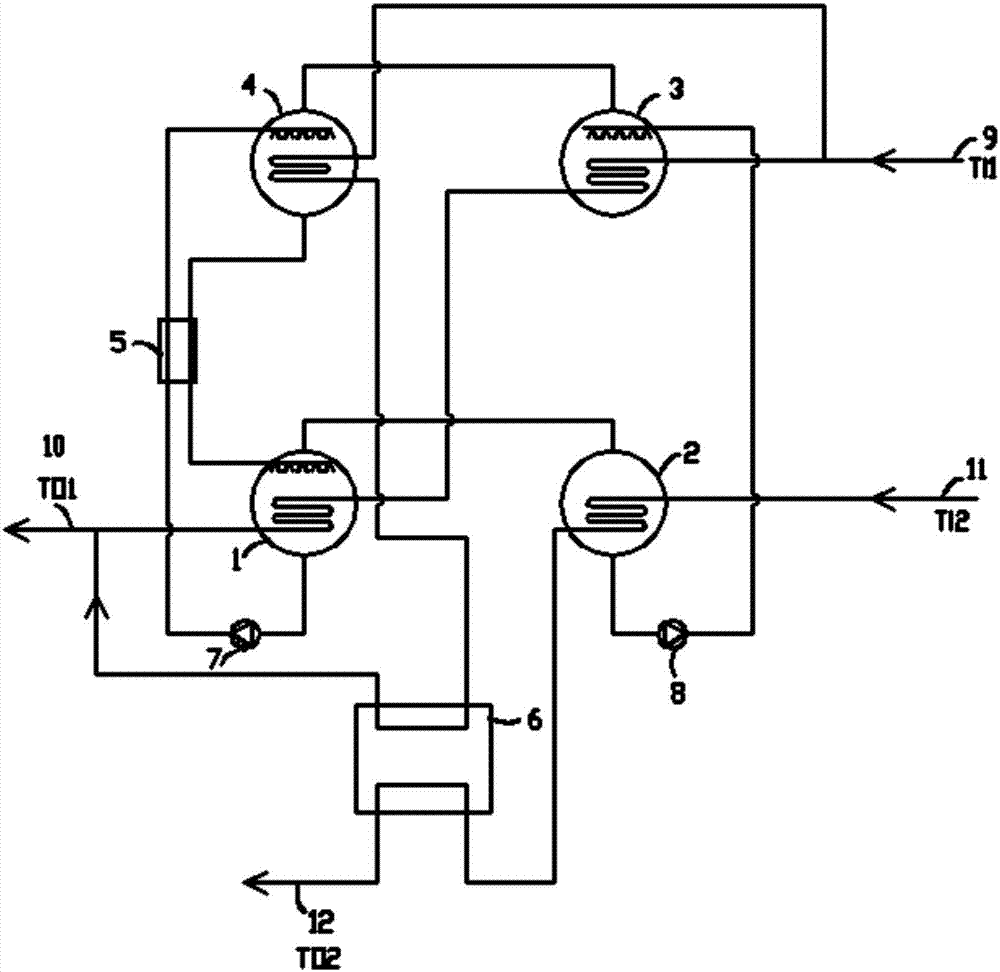

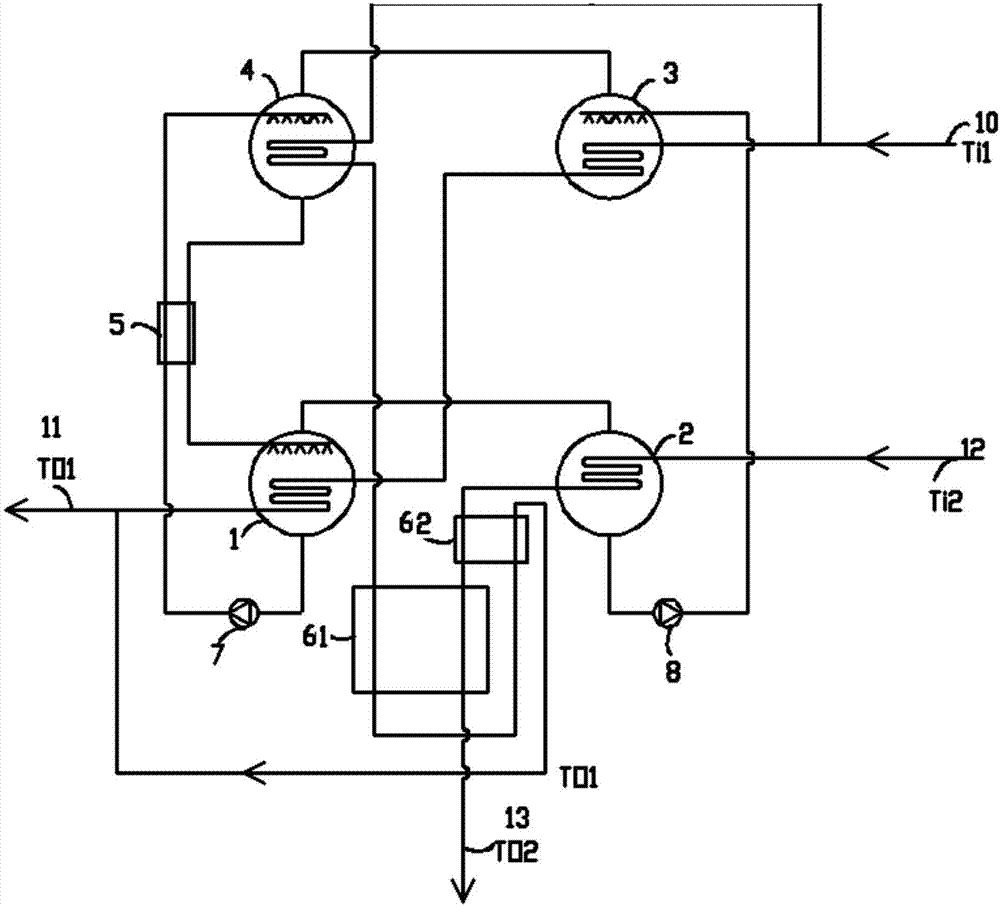

[0015] Aiming at the technical problem of high investment cost when the second type of absorption heat pump is applied to the heated source with large temperature difference pointed out in the prior art, this paper conducts in-depth research. The study found that: the COP of the existing single second-type absorption heat pump is relatively low, usually 0.48 for a single-stage temperature increase, and 0.32 for a two-stage temperature increase. The so-called COP value is the energy efficiency ratio. The ratio of heating capacity to input heat.

[0016] That is to say, the key to reducing unit input cost is to increase the COP of the second type of absorption heat pump, aiming at how to increase the COP of the second type of absorption heat pump and reduce energy waste. In this paper, the second type of absorption heat pump in the prior art is studied in detail.

[0017] The second type of absorption heat pump in the prior art includes a generator, a condenser, an absorber and...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap