Hydraulic fracture tester and method for simulating permeable liquid of suddenly-heightened water head

A hydraulic splitting and permeability technology, applied in the direction of applying stable tension/pressure to test the strength of materials, instruments, scientific instruments, etc., to achieve the effect of good water tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

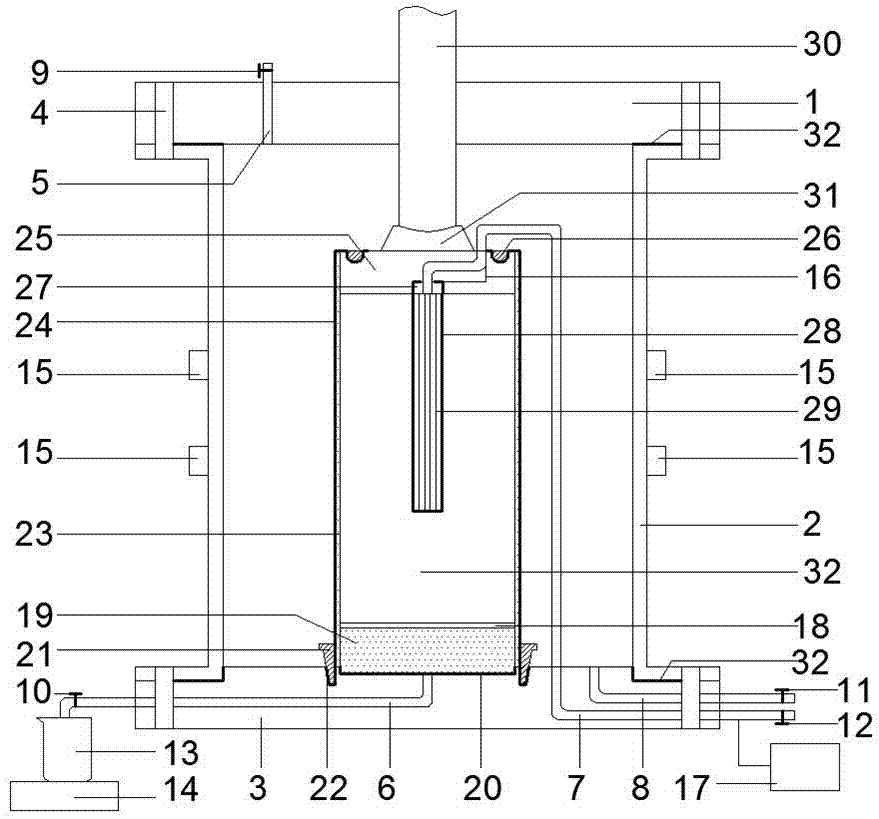

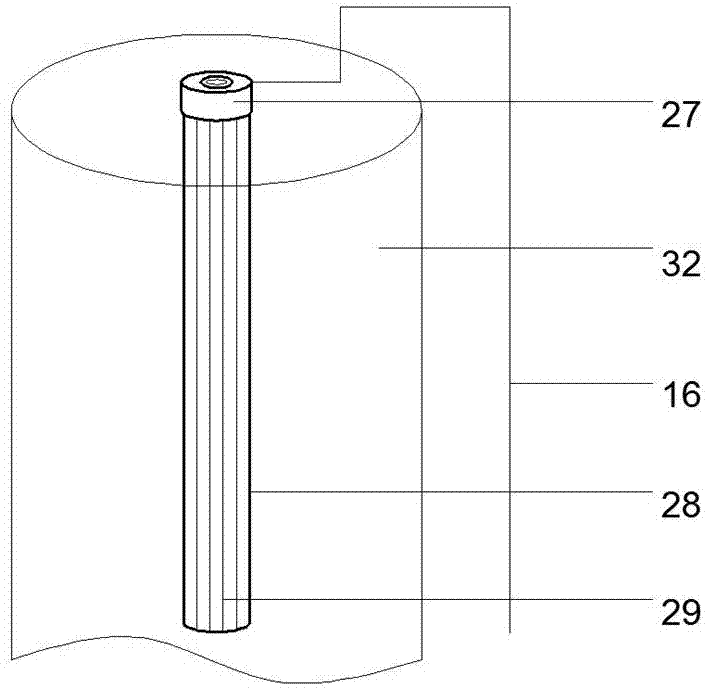

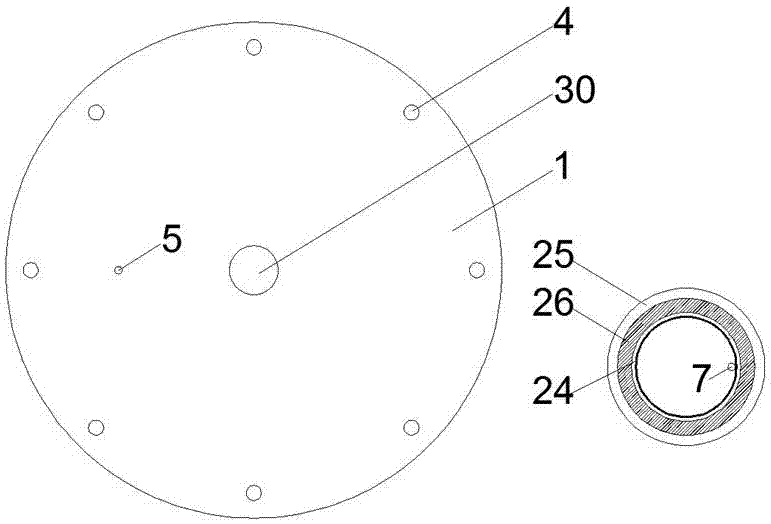

[0033] The hydraulic splitting test instrument of the simulated sudden increase of high water head permeability liquid of the present embodiment is as follows: Figure 1-5As shown, the device mainly includes 1 pressure chamber top cover, 2 cylinder, 3 pressure chamber base, 4 bolts, 5 air outlet, 6 water outlet pipe, 7 first water inlet pipe, 8 second water inlet pipe, 9 air outlet valve, 10 outlet pipe valve, 11 first control valve, 12 second control valve, 13 measuring cylinder, 14 electronic balance, 15 acoustic emission sensor, 16 wire, 17 power supply, 18 impermeable steel plate, 19 permeable plate, 20 first water-stop rubber , 21 wedge-shaped steel ring, 22 second water-stop rubber, 23 permeable cylinder, 24 rubber sleeve, 25 top block, 26 steel ring, 27 hollow cylinder, 28 impermeable membrane, 29 resistance wire, 30 axial force steel rod, 31 Axial force backing plate, 32 hydraulic splitting test piece, 33 sealing gasket; the pressure chamber top cover 1, cylinder 2, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com