Mesochite, display module, display device and assembling method of display module

A technology for display components and components, applied in nonlinear optics, instruments, optics, etc., can solve problems such as narrowing the frame of mobile phones, and achieve the effect of reducing the width of the bottom surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

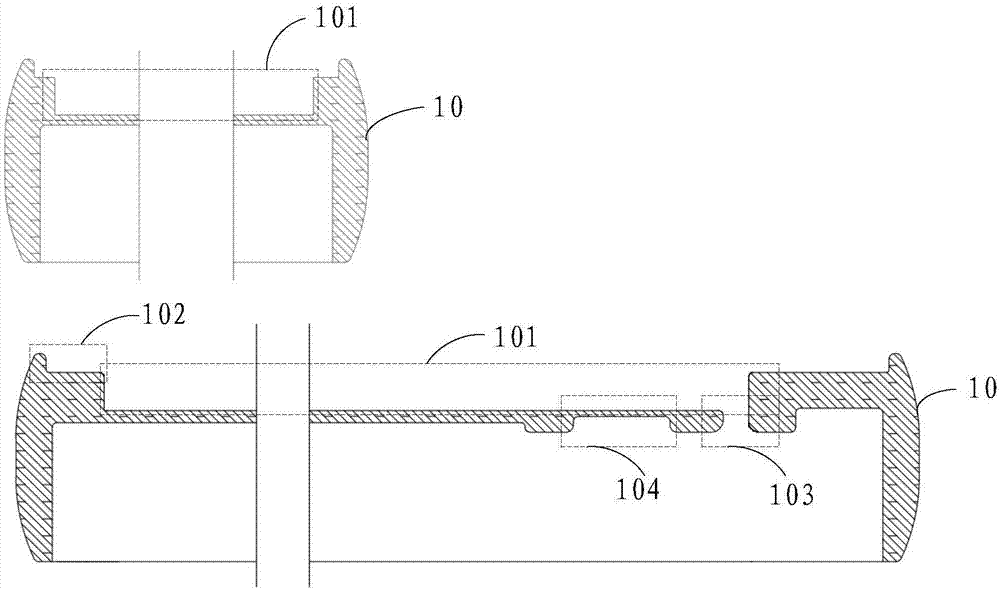

[0040] An embodiment of the present invention provides a middle case.

[0041] The middle case 10 is provided with a first groove 101 for carrying a backlight assembly;

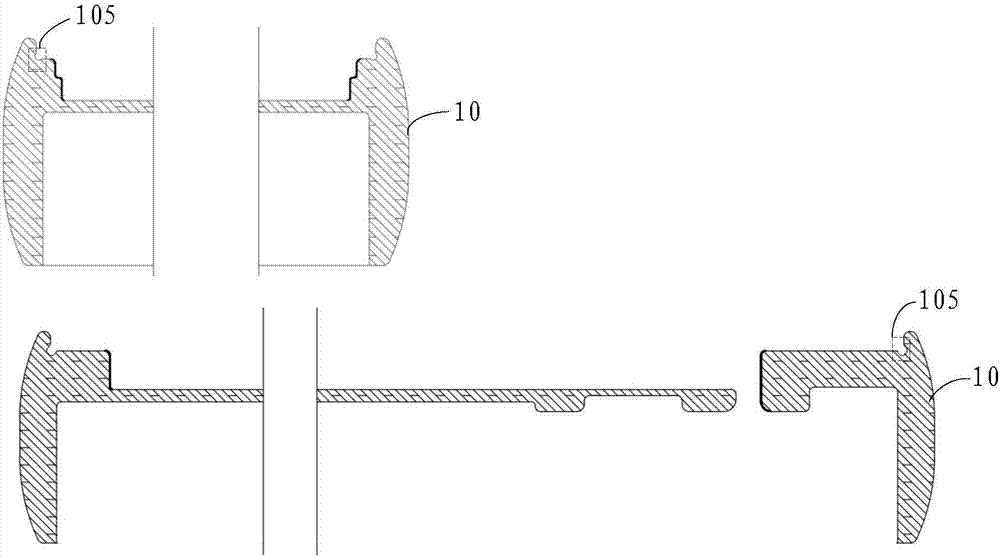

[0042] The top of the side wall of the first groove 101 is provided with a second groove 102, and the bottom surface and the side surface of the second groove 102 form a right angle for assembling the glass cover;

[0043] The bottom surface of the first groove 101 is provided with a slot 103 for the flexible circuit board to protrude from the slot 103 and bend to the back of the first groove 101;

[0044] The back of the first groove 101 is provided with a third groove 104 for placing chips.

[0045] In this embodiment, the middle case 10 is provided with a first groove 101, and the backlight assembly can be assembled in the first groove 101, so that the sidewall of the first groove 101 can protect the backlight assembly. refer to figure 1 In the middle case shown, the top of the side wall of the first gr...

Embodiment 2

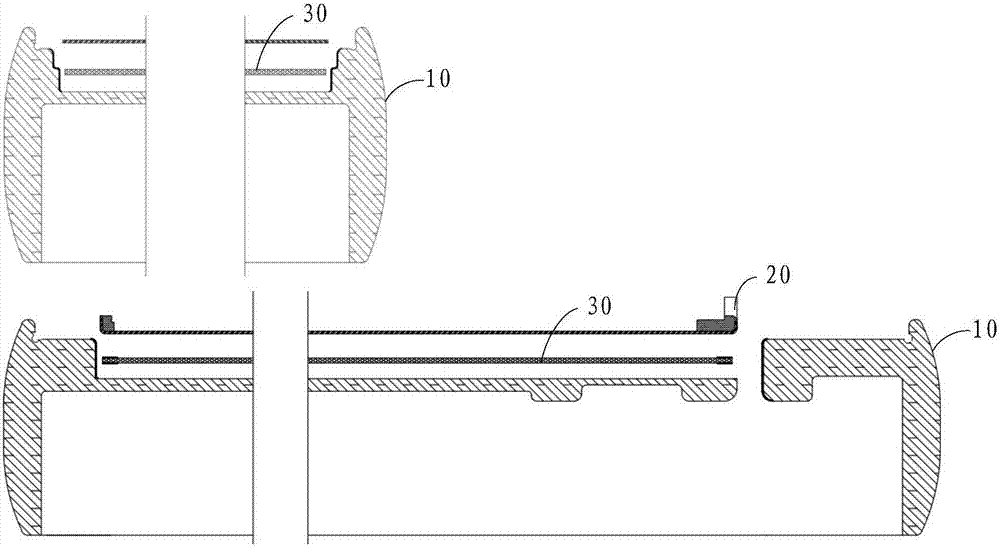

[0054] An embodiment of the present invention provides a display component. The display assembly includes the middle case 10 described in Embodiment 1, a plastic frame 20 , a foam 30 , a backlight assembly 40 , a liquid crystal display assembly 50 , an optical bonding glue 60 and a cover glass 70 .

[0055] The plastic frame 20 is arranged inside the short side wall of the first groove 101 of the middle shell 10;

[0056] The foam 30 , the backlight assembly 40 , the liquid crystal display assembly 50 , the optical adhesive 60 and the cover glass 70 are stacked on the middle casing 10 .

[0057] In this embodiment, the glue frame 20 is disposed on the inner side of the short side wall of the first groove 101 . Specifically, the metal plastic frame can be formed by injecting plastic frame 20 on the short side of the metal sheet, and the metal plastic frame is embedded in the first groove 101, and the plastic frame 20 is located inside the short side wall of the first groove 10...

Embodiment 3

[0068] A display device provided by an embodiment of the present invention. The display device includes the display component described in the second embodiment.

[0069] In this embodiment, the display device includes the display assembly described in Embodiment 2, and the display assembly includes the middle case 10 described in Embodiment 1, as well as the plastic frame 20, the foam 30, the backlight assembly 40, the liquid crystal display assembly 50, the optical sticker Glue 60 and cover glass 70. The middle case 101 is provided with a first groove 101 carrying a backlight assembly; the top of the side wall of the first groove 101 is provided with a second groove 102, and the bottom surface and the side surface of the second groove 102 form a right angle, which is used for assembling glass Cover plate; the bottom surface of the first groove 101 is provided with a slot 103, which is used for the flexible circuit board to protrude from the slot 103 and bend to the back of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com