Pressing Die for Multi-stage Adjustable Tantalum Electrolytic Capacitor Using Vibration Assist

A technology for tantalum electrolytic capacitors and pressing molds, which is applied in the manufacture of capacitors, capacitors, circuits, etc., can solve the problems of complex structure, low efficiency, and low energy utilization rate, and achieve complex structure, wide application prospects, and volume reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

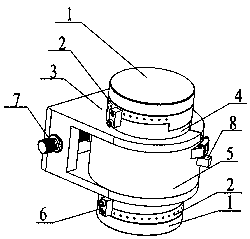

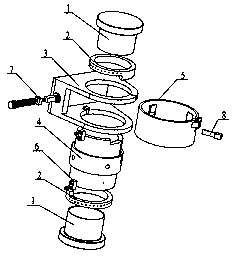

[0055] Specific implementation mode one: combine Figure 1~Figure 16 This embodiment will be described.

[0056] This embodiment provides a specific implementation of a vibration-assisted multi-stage adjustable tantalum electrolytic capacitor pressing die. The vibration-assisted multi-stage adjustable tantalum electrolytic capacitor pressing die can be a low-friction stacked tantalum electrolytic capacitor pressing die; the low-friction stacking tantalum electrolytic capacitor pressing die includes a pressing die 1, a height adjustment ring 2, and a cage 3. Female mold component 4, fixed sleeve 5, limit component 6, anti-friction excitation component 7 and pressure pole block 8; said die 1 is connected with the height adjustment ring 2, and the height adjustment ring 2 is opposite to the pressure die 1 Play a position-limiting role; the height-adjusting ring 2 and the female mold assembly 4 are connected through the space-limiting assembly 6; Function; the female mold assemb...

specific Embodiment approach 2

[0066] Specific implementation mode two: combination Figure 17~Figure 30 This embodiment will be described.

[0067] This embodiment provides another specific embodiment of a vibration-assisted multi-stage adjustable tantalum electrolytic capacitor pressing die. The vibration-assisted multi-stage adjustable tantalum electrolytic capacitor pressing die can be a flexible hinged tantalum electrolytic capacitor pressing die; the flexible hinged tantalum electrolytic capacitor pressing die includes a punch 101, a height adjustment ring 102, and a tightening ring 103 , mold body assembly 104, fixed installation sleeve 105, positioning device 106, vibrating assembly 107 and electric limit block 108; Described punch 101 is connected with height adjustment ring 102, and height adjustment ring 102 is limited to punch 101 The position effect; the height adjustment ring 102 is connected with the phantom assembly 104; the fastening ring 103 is connected with the phantom assembly 104 by s...

specific Embodiment approach 3

[0077] Specific implementation mode three: combination Figure 31~Figure 41 This embodiment will be described.

[0078] This embodiment provides another specific embodiment of a vibration-assisted multi-stage adjustable tantalum electrolytic capacitor pressing die. The vibration-assisted multi-stage adjustable tantalum electrolytic capacitor pressing die can be an oblique chip type tantalum electrolytic capacitor pressing die; body 203, electrode fixing block 204, and piezoelectric sheet 205; the stamping die body 201 is connected to the height adjustment device 202 through surface contact; the height adjustment device 202 is connected to the mold body 203 through surface contact; the electrode fixing block 204 is connected with the mold body 203 by means of interference fit; the piezoelectric sheet 205 is connected with the mold body 203 by adhesive.

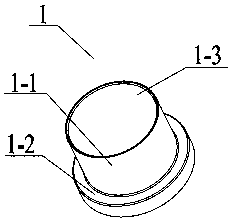

[0079] The stamping die body 201 is provided with a round table 201-1, a base 201-2, a molding surface 201-3 and an outer c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com