Pancake proportion uniformizing equipment and method for shredded cake production

A hand-grabbing and proportioning technology, which is applied to the field of even-proportioned pancake production equipment for hand-grasping cakes, can solve problems such as equipment operation interference, easy sticking of the bottom of the noodles, affecting the taste of the hand-grasping cakes, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

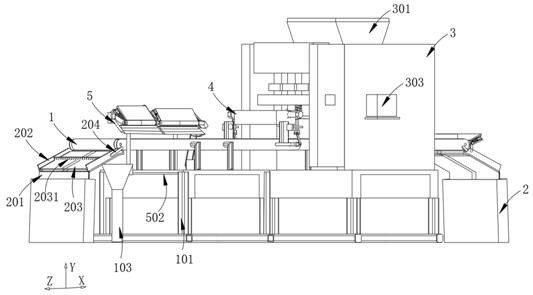

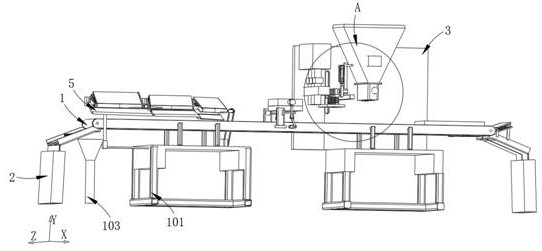

[0060] like Figure 1-5 Show, this implementation provides a uniform equipment for the production of hand -grasping cake production, including: transmission unit 1, and also includes:

[0061] The bottom oil return unit 2 is used to set the oil return unit 2 of the oil on the transfer unit 1 on the side of the transmission unit 1;

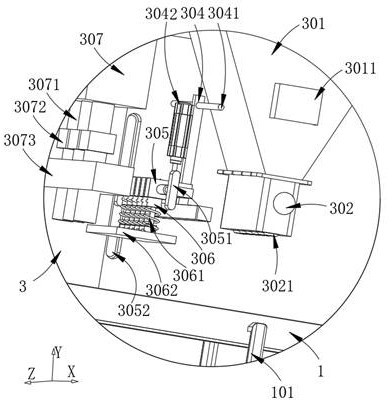

[0062] The top feed unit 3, used for the surface of the opposite side of the onion, the top feed unit 3 set at the top 3 set at the top of the transmission unit 1;

[0063] Pressure unit 4, used on the surface of the opposite side of the top oil for pressing oil unit 4 set on the side of the top 3 in the top 3;

[0064] The pressure unit 4, including the outer rod 401, the outer linked rod 401 used for linkage through its bottom movement rod 402 and the limited board 4021 sliding connection, which is Link 404 activity connection, which is connected by the connecting rod 404 through swinging board 405 and the motion column 406 rotating connection.

[006...

Embodiment 2

[0091] like Figure 11 Show, this implementation provides a uniform method for the proportion of hand -grasping cake production, including:

[0092] Step 1. Transfer oil: Quantitative oil unit 205 set on the outside of the transmission unit 1, rotate the surface of the transmitting unit 1 to quantitative oil;

[0093] Step 2, band conveyor: transmitting unit 1 transmits the noodles to the feeding port 3021, pressure plate 3062, oil pipe 3071, oil pressure unit 4, and rolled board unit 5 for processing;

[0094] Step 3: Onion flowers upper pressure: Transfer unit 1 will sprinkle the onion on the upper surface on the opposite side of the side of the feeding port 3021, and when the onion flowers on the surface of the surface to the lower end of the pressure plate 3062, the onion will be compacted by the pressure plate 3062 compact. To the inside of the face;

[0095] Step 4. Pressing oil: After compacking, the noodle belt containing the onion will be poured by the oil pipe 3071 in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com