Manufacturing method of micro-LED device array unit

A technology of LED devices and array units, which is applied in the production field of micro-LED device array units, and can solve problems such as difficulties, precise grasping, displacement, difficult placement, complex manufacturing process of OLED display screens, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0064] The GaN-based LED epitaxial wafer includes a blue light band and / or a green light band, the wavelength range of the blue light band is 430nm-490nm, and the wavelength range of the green light band is 520nm-580nm. This embodiment is a GaN-based blue LED epitaxial wafer.

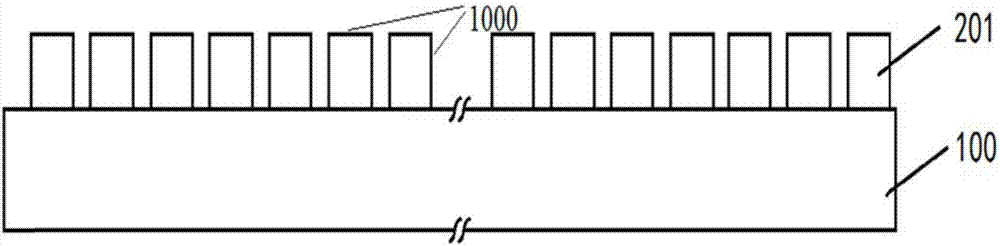

[0065] Select a sapphire substrate 100; deposit various material layers on the sapphire substrate to form a GaN-based blue LED epitaxial wafer; photolithographically etch the GaN-based blue LED epitaxial wafer to the sapphire substrate to form a GaN-based blue light micro LED mesa array 1000, GaN The blue-based micro-LED mesa array 1000 includes a plurality of GaN-based blue-light micro-LED mesas 201 . The arrangement period of the GaN-based blue light micro LED mesa array 1000 is 20 μm×20 μm in the longitudinal direction and the transverse direction respectively.

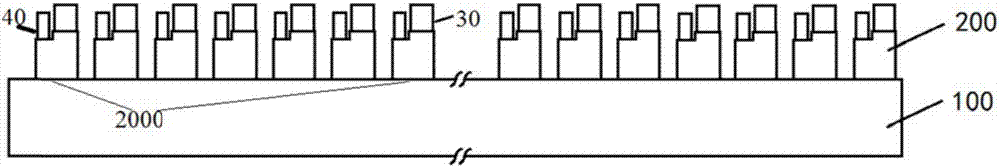

[0066] On each of the above-mentioned GaN-based blue light micro LED mesa array 201, a NiAg metal pn electrode layer and 5 pairs of TiW is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com