Carbon fiber energy-saving heat generation floor tile line and line group and floor heating system

A carbon fiber heating and carbon fiber technology, applied in the carbon fiber field, can solve the problems of not meeting the use requirements, low heat resistance of the sheath, and increased heating power, and achieve the effects of reducing heating power, increasing resistance, and reducing the number of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

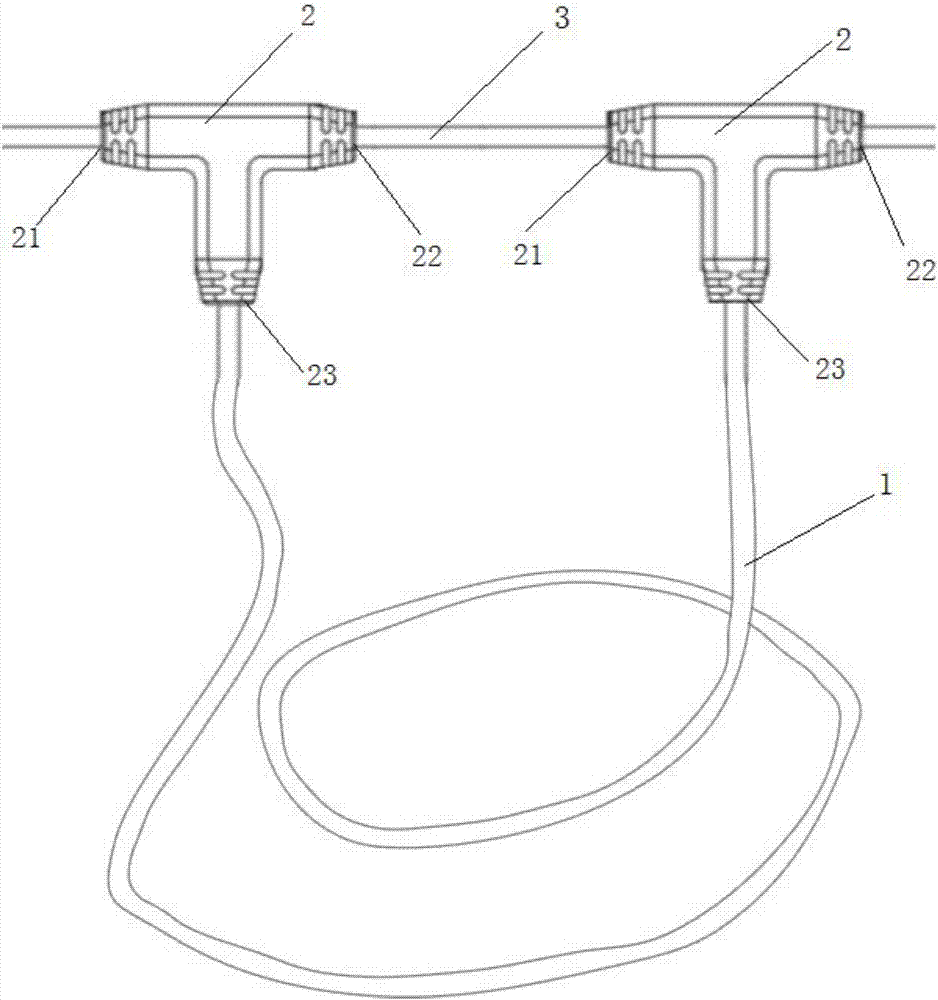

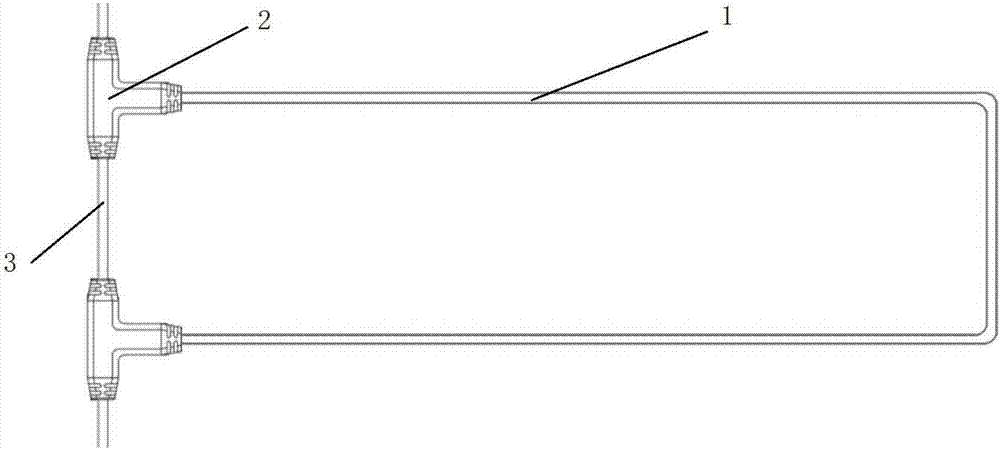

[0029] In one embodiment of the present invention, a carbon fiber energy-saving heating floor tile wire is provided, see figure 1 and figure 2 , the carbon fiber energy-saving heating floor tile wire includes a heating wire 1, a connecting wire 3 and two tee joints 2, the two tee joints 2 are separated by a certain distance, and one end of the connecting wire 3 passes through the first tee in turn The first joint part 21 and the second joint part 22 of the joint 2 pass through the first joint part 21 and the second joint part 22 of the second three-way joint 2 in sequence, and one end of the heating wire 1 extends into the first joint part 21 and the second joint part 22 of the second three-way joint 2. The third joint part 23 of the first three-way joint 2 is connected to the connecting wire 3 , and the other end of the heating wire 1 extends into the third joint part 23 of the second three-way joint 2 and is connected to the connecting wire 3 .

[0030] The heating wire 1 ...

Embodiment 2

[0038] Different from Embodiment 1, there are three carbon fiber heating element wires 11 in this embodiment, and each carbon fiber heating element wire 11 includes 4000 carbon fiber filaments. Compared with a single carbon fiber heating wire of 12K specification (12000 carbon fiber heating wires) in the prior art, the reduction of power consumption can also be achieved.

[0039] Correspondingly, the carbon fiber heating wires of the three carbon fiber heating unit wires 11 are all wrapped by the insulating layer 12, the thermally conductive protective layer 13 is wrapped around the three carbon fiber heating unit wires 11, and the carbon fiber energy-saving heating floor tile wires made of other carbon fiber heating unit wires 11. Not listed here.

Embodiment 3

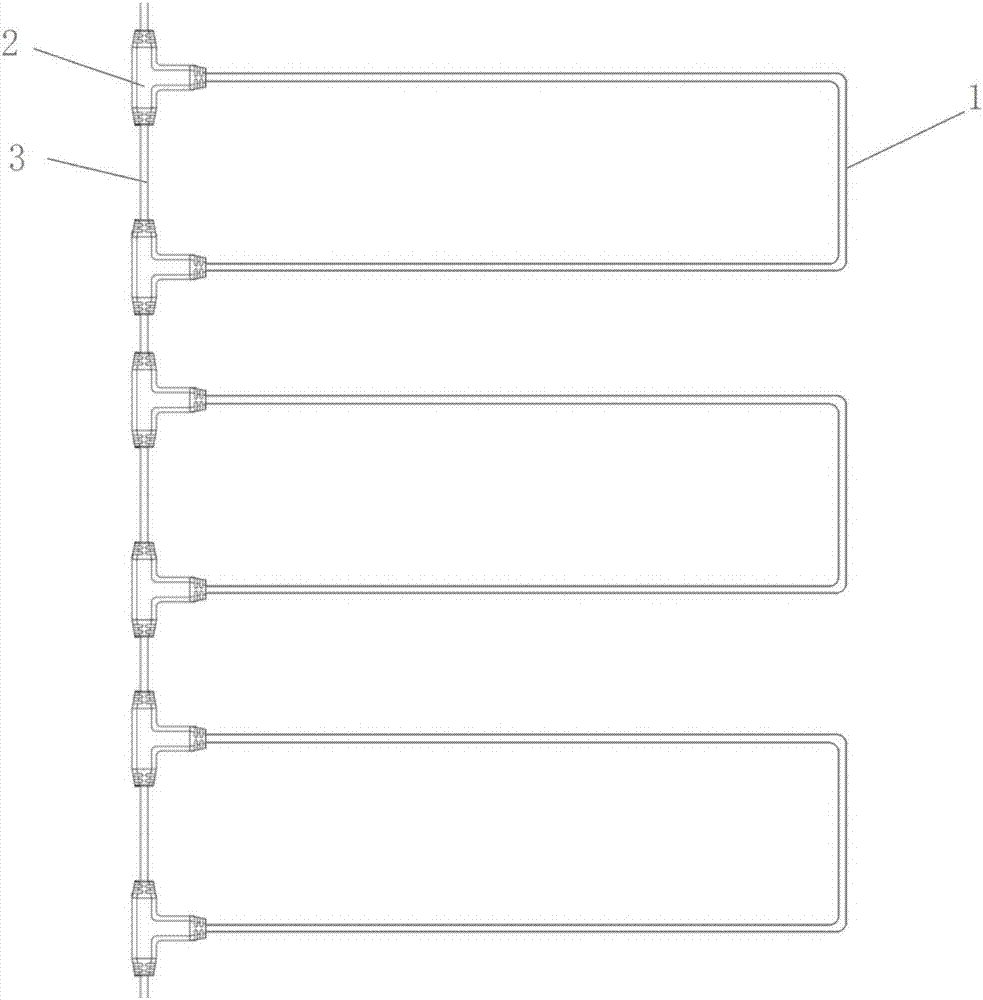

[0041] On the basis of Embodiment 1, the present invention provides a carbon fiber energy-saving heating-generating floor tile wire set, wherein the wire set includes a plurality of carbon fiber energy-saving heating-generating floor tile wires as described in Embodiment 1.

[0042] As a preferred embodiment, a plurality of carbon fiber energy-saving heating floor tile lines share one connecting wire 3, see image 3 , or, the connecting wires 3 of a plurality of carbon fiber energy-saving heating floor tile wires are connected in series.

[0043] In an embodiment of the present invention, a floor heating system is provided, the floor heating system includes floor tiles, a concrete layer and one or more carbon fiber energy-saving heating floor tile wire sets as described above, the wire sets are arranged on the concrete Below the layer, the floor tiles are laid above the concrete layer.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap