A constant speed drive shaft moving joint assembly machine

A constant-velocity drive shaft and assembly machine technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve problems such as inability to adapt to automated production line operations, poor product consistency and safety, and low production efficiency, so as to ensure product quality Consistency and safety, increased automation, and increased productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

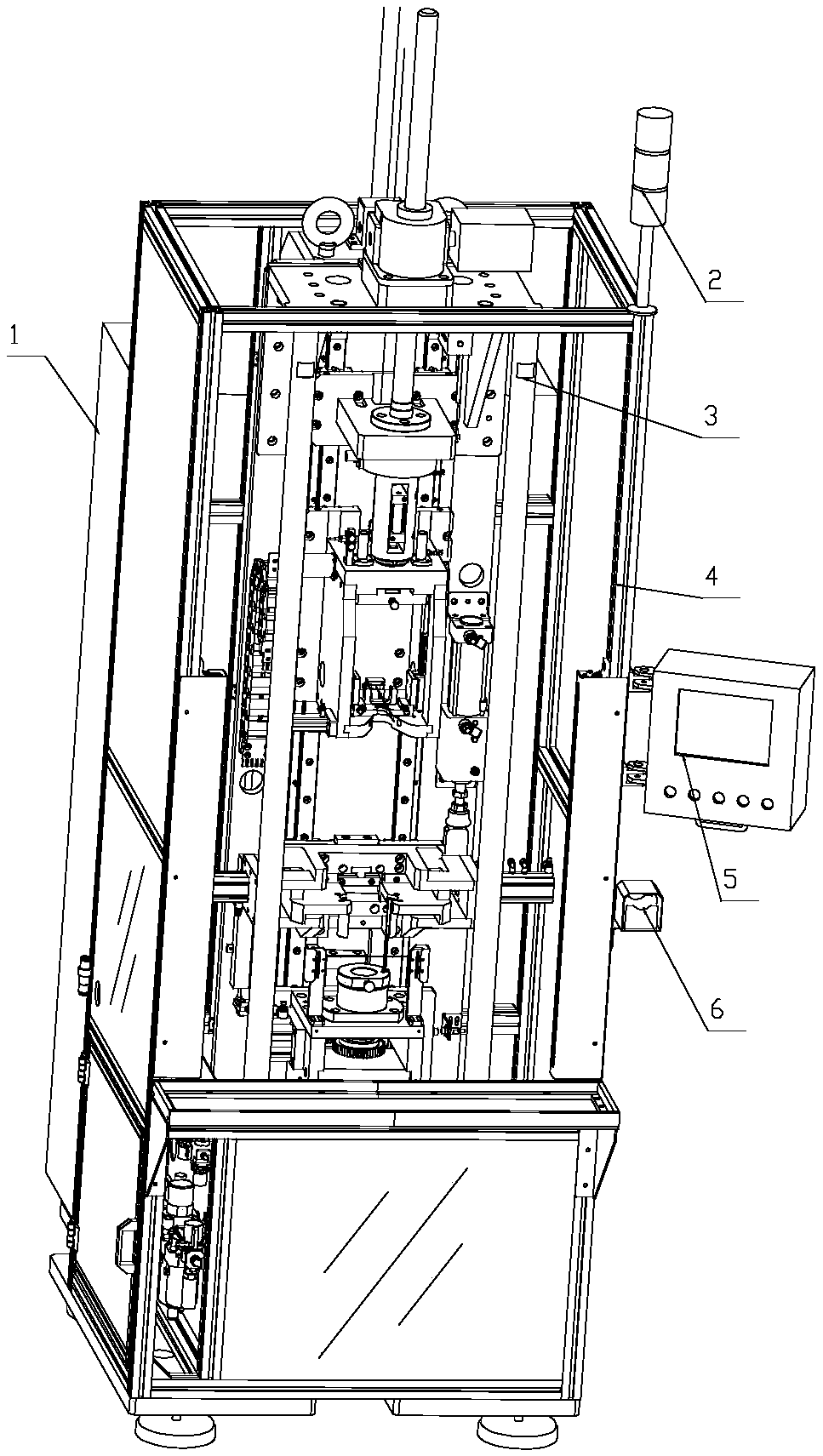

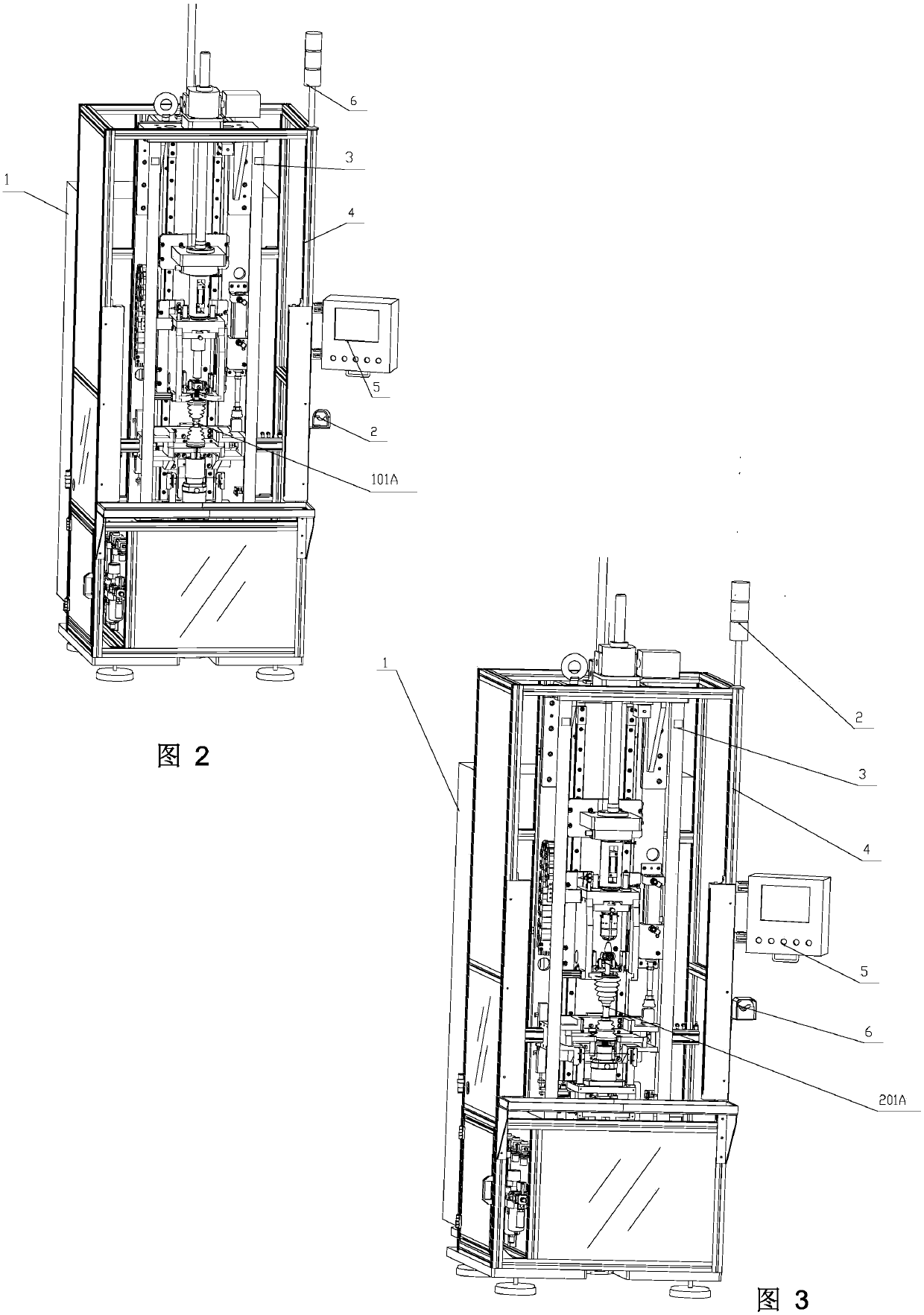

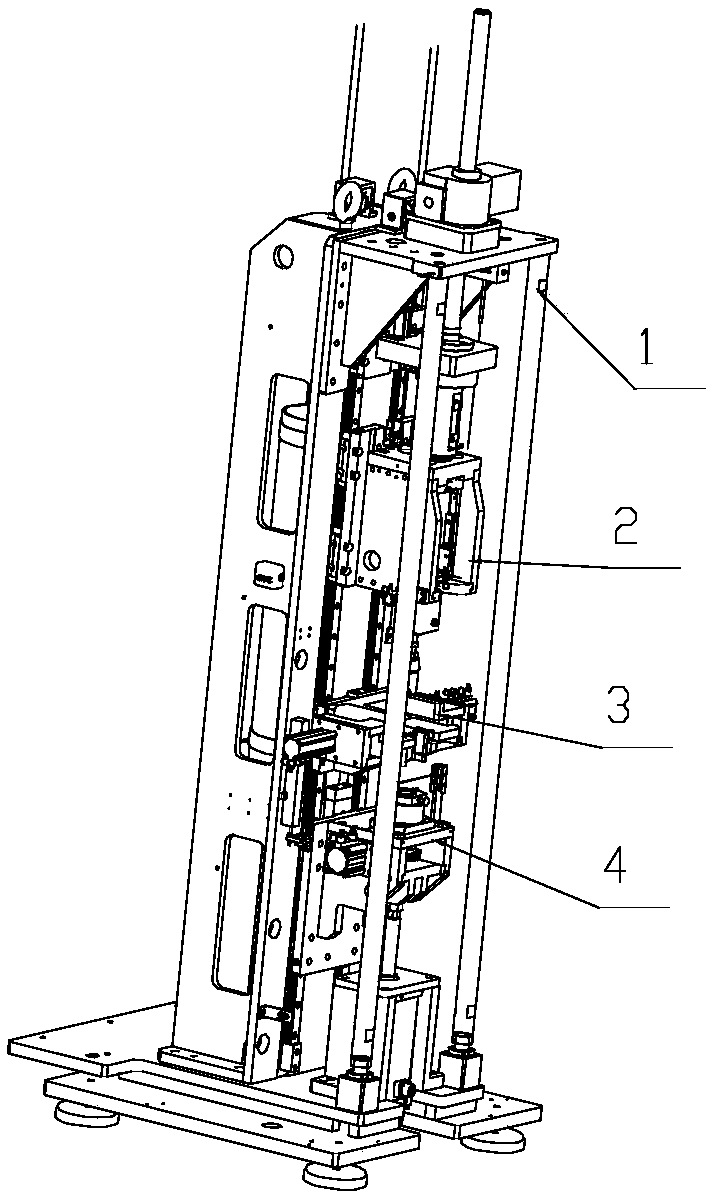

[0045] Such as figure 1 , figure 2 , Figure 4 to Figure 16 As shown, a constant speed drive shaft moving section assembly machine includes an electrical cabinet 1, a three-color warning light 2, a button control cabinet 5, a manual button panel 6, a host and a moving section assembly tool, the host includes a rack assembly, and the upper The moving mechanism, the middle moving mechanism and the lower moving mechanism, the upper moving mechanism, the middle moving mechanism and the lower moving mechanism are all slidably connected to the frame assembly, and the upper moving mechanism, the middle moving mechanism and the lower moving mechanism are connected to a PLC control system , the main working devices of the PLC control system are installed in the electrical cabinet 1, and the assembly tooling of the moving section is connected with the upper moving mechanism and the lower moving mechanism. The electrical cabinet 1 is arranged on the back of the main engine, and the th...

Embodiment 2

[0048] Such as image 3 , Figure 17a to Figure 22 The moving joint assembly tool is a three-pin joint assembly tool, which is composed of upper and lower two-section modules. The three-pin joint assembly tool includes an upper tool outer cylinder 204, and the upper tool outer cylinder 204 is provided with a light blocking sheet 201, Block 211, revolving pin 206, revolving pin 206 is provided with swing claw 207, swing claw 207 is provided with O-ring 208, outer cylinder 204 is also provided with flange 202, flange 202 is provided with first guide pin 203, the outer cylinder 204 is also provided with an inner cylinder 205, the inner cylinder 205 is provided with an upper top 210, the upper top 210 is provided with a second guide pin 209, and the lower top fixing seat 212 of the lower tooling is provided with a compression spring 213, the stage clip 213 is provided with the lower top 214, and the top holder 212 is also provided with a flange 215 and a guide spline sleeve 216. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com